Automatic heating and pressurization system for polymer soft pack battery

A soft pack battery, polymer technology, applied in secondary battery manufacturing, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of high labor cost and production cost, easy scrapping of batteries, low battery output, etc. Achieve the effect of saving energy, reducing losses, and increasing battery output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

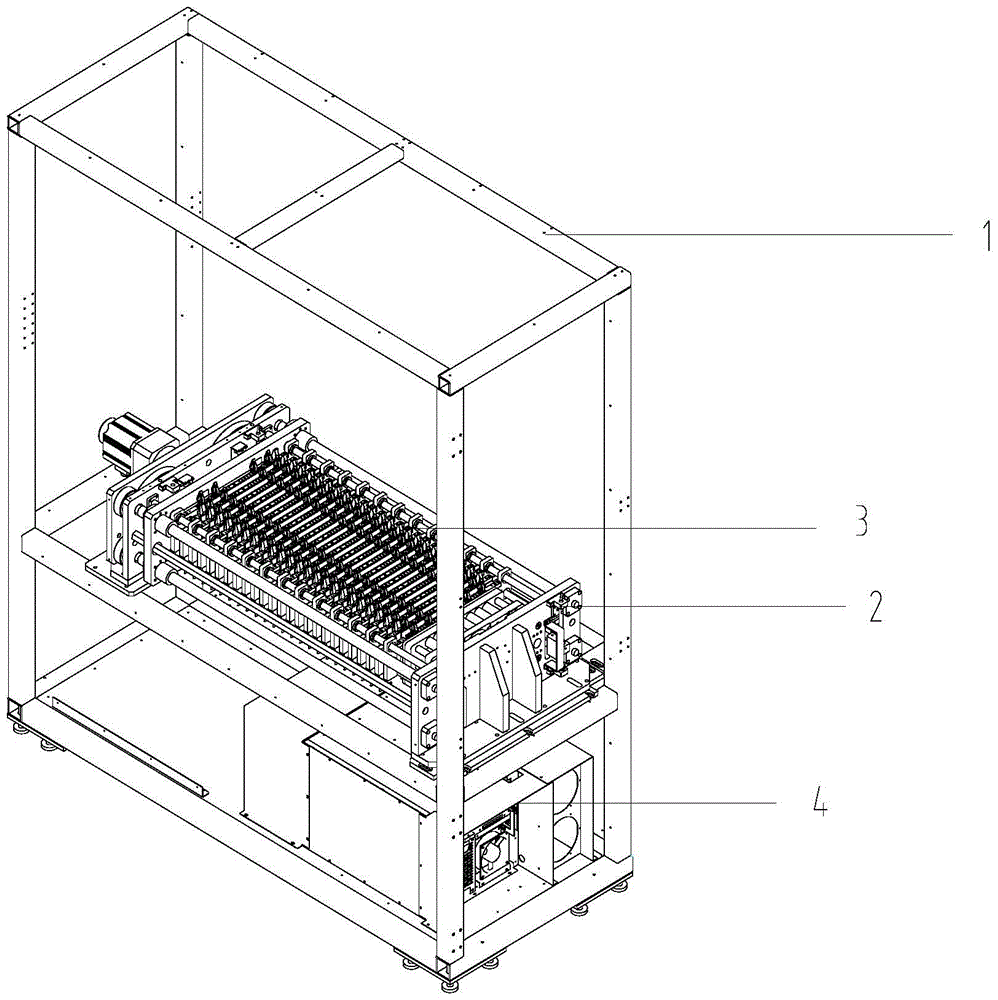

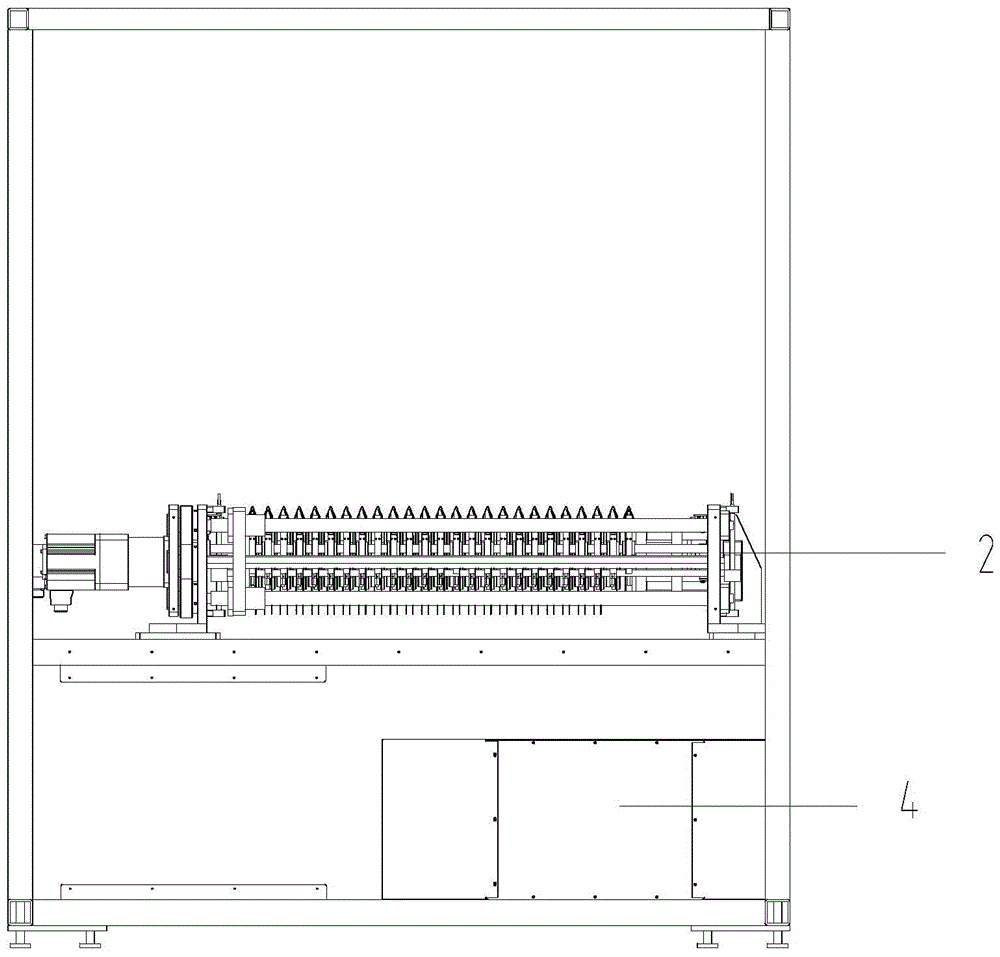

[0036] refer to Figure 1 to Figure 8c , the automatic heating and pressurizing formation system of the polymer pouch battery, including a frame 1, a pressure control device 2, several heating clamp bodies 3 and a formation mechanism 4 for clamping and heating the polymer pouch battery, the pressure The control device 2 and the formation mechanism 4 are respectively arranged on the frame 1, and several of the heating clamp bodies 3 are arranged in parallel on the pressure control device 2, and the heating clamp bodies 3 correspond to the formation mechanism 4 one by one. .

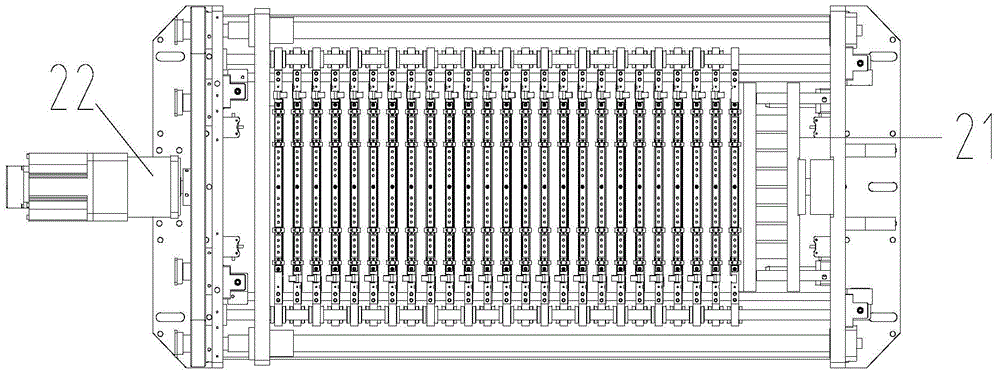

[0037] The pressure control device 2 includes a pressure detection and automatic adjustment mechanism 21 and a power transmission mechanism 22. The pressure detection and automatic adjustment mechanism 21 and the power transmission mechanism 22 are respectively arranged at both ends of the frame 1. The heating clamp body 3 is located between the pressure detection and automatic adjustment mechanism 21 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com