Lower-hook-molding type commutator hook mechanism

A forming type commutator technology, applied in the field of fully automatic motor commutator assembly equipment, can solve the problems of large space and cost, inconvenient installation and operation, and inability to carry out at the same time, so as to reduce the occupied space, Easy to install and operate, easy to transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

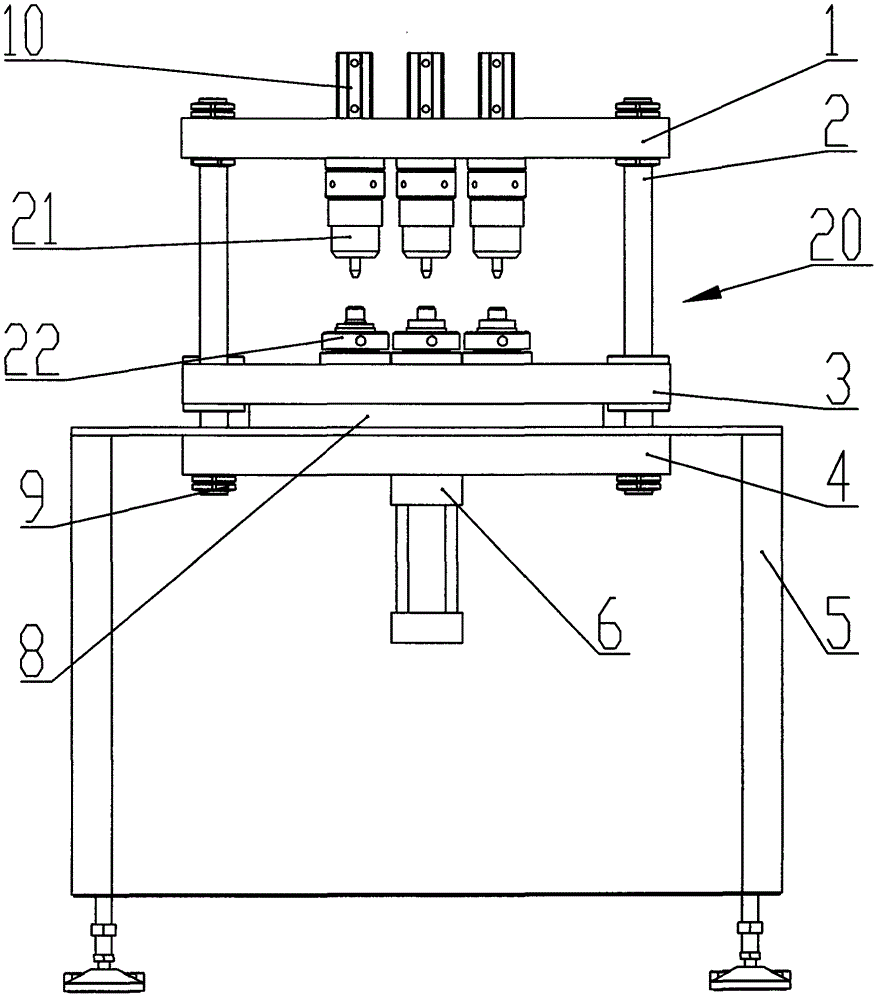

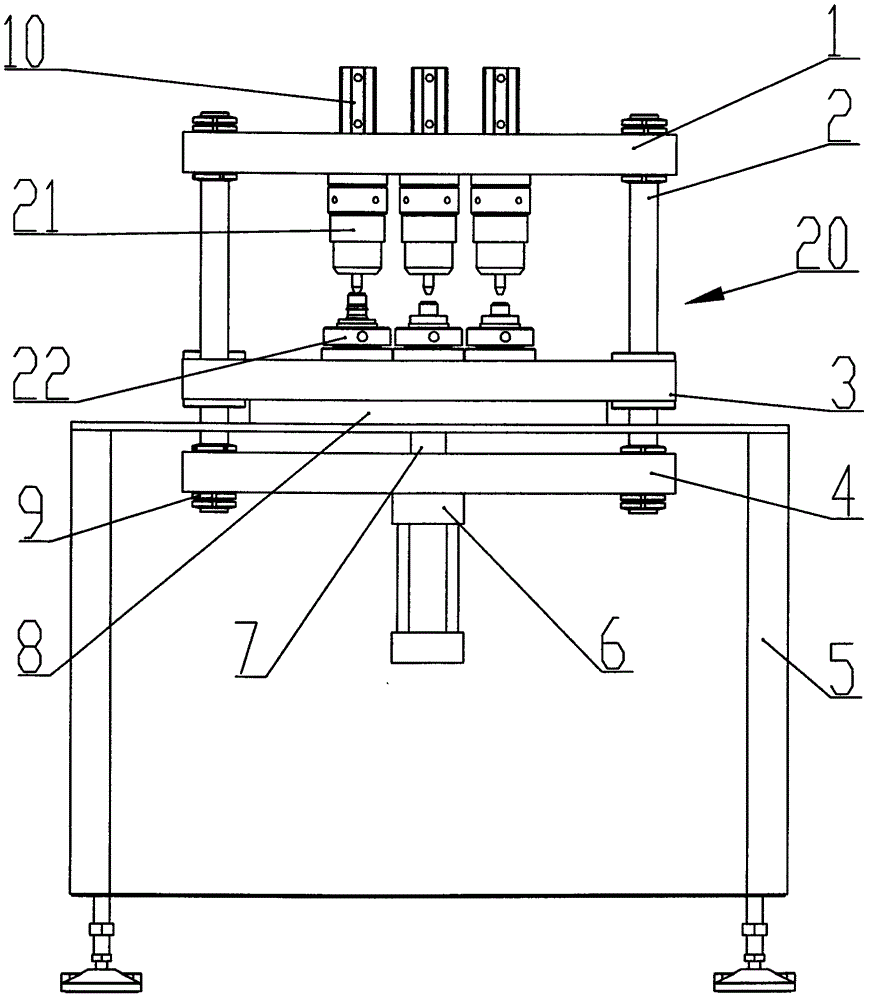

[0012] refer to figure 1 , figure 2 It can be seen that the lower hook forming type commutator hook mechanism of the present invention includes a frame 5, on which a fixed pressure plate 3 is installed on the frame 5 (through the fixed pressure plate backing plate 8), and at both ends of the fixed pressure plate 3 A guide post 2 is installed, and an upper pressing plate 1 and a lower pressing plate 4 are respectively installed at both ends of the guiding post 2 (and locked with lock nuts 9); the lower hook assembly die 22 is installed on the fixed pressing plate 3 , upper crotch assembly mold 21 is housed under described upper pressing plate 1, and power execution source 6 (being an oil cylinder or an air cylinder, sharing one piece and getting final product) is housed under described lower pressing plate 4.

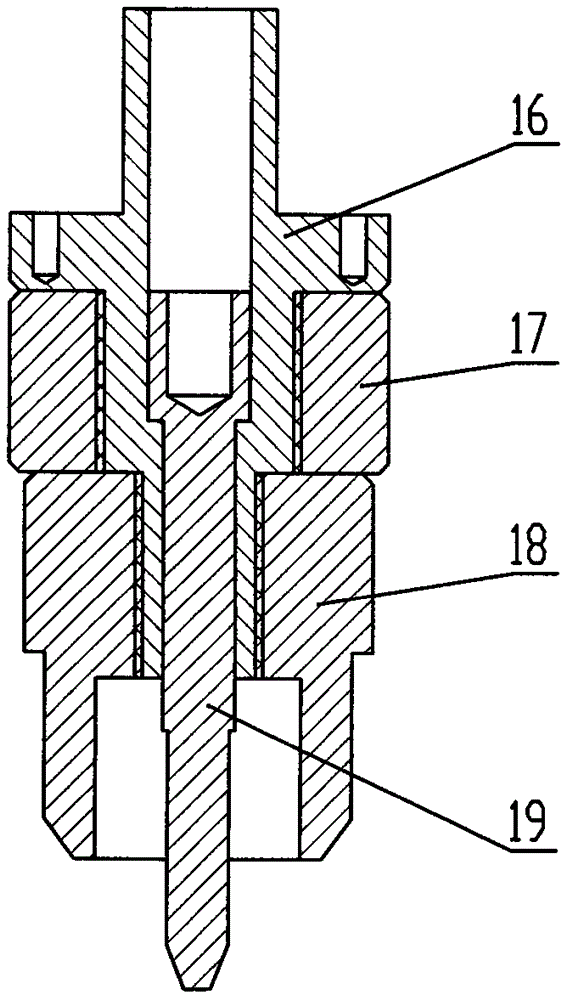

[0013] Such as Figure 5 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com