Crush ridging machine used for surface fertilization and surface fertilization method of crush ridging machine

A powder ridge machine and a powder ridge technology are applied in the field of ridge tillage machinery, which can solve the problems of single function of agricultural machinery and inability to adjust the fertilization device, etc., and achieve the effect of simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

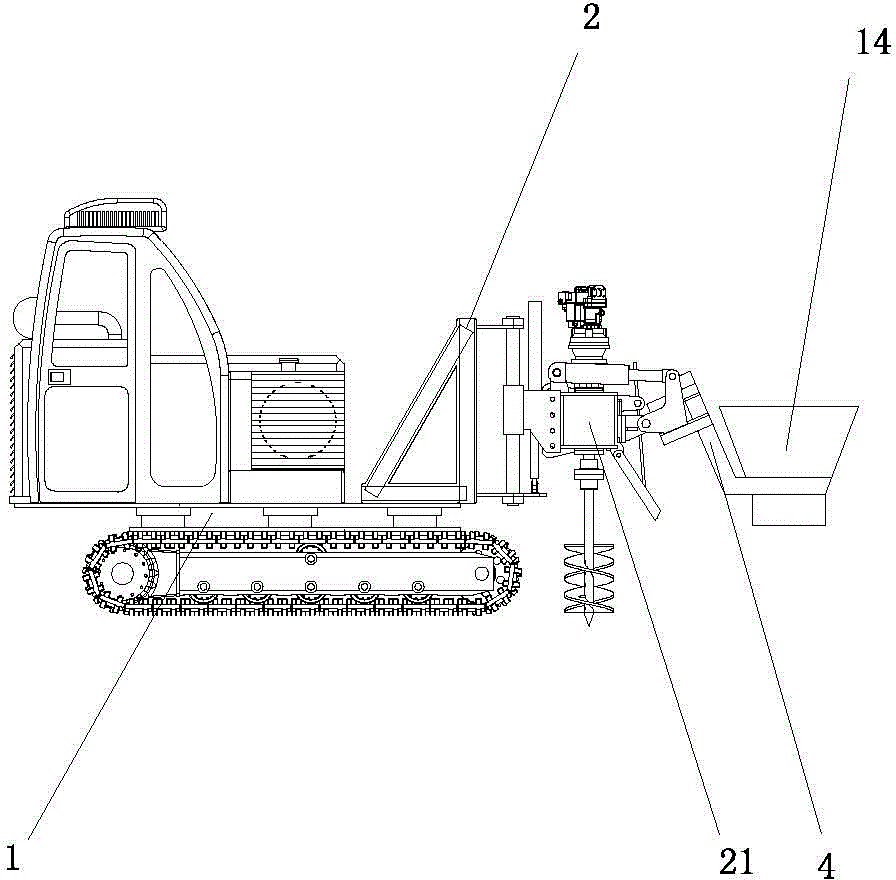

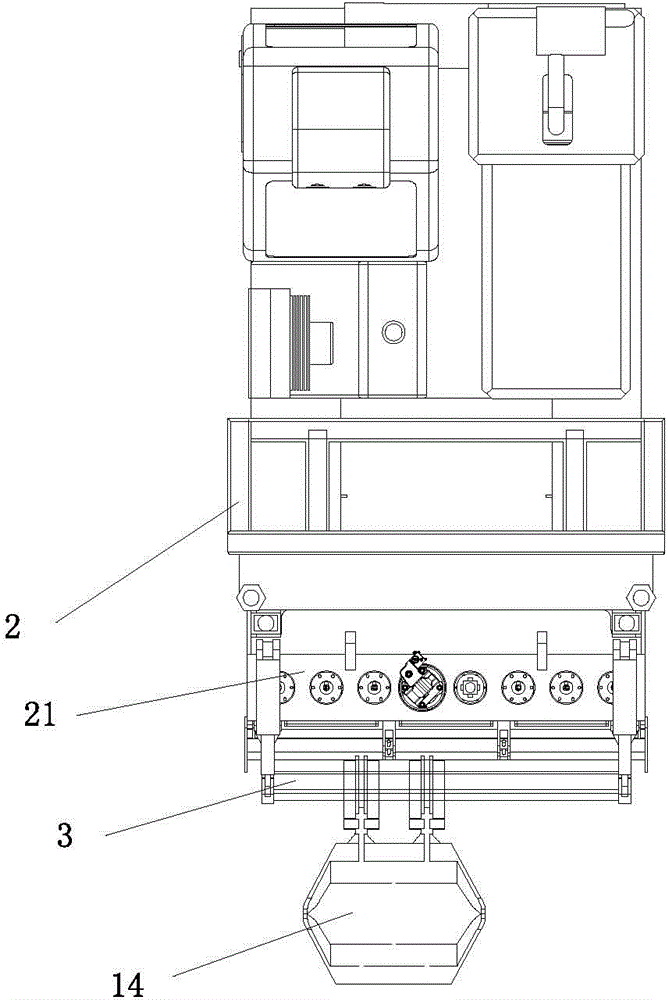

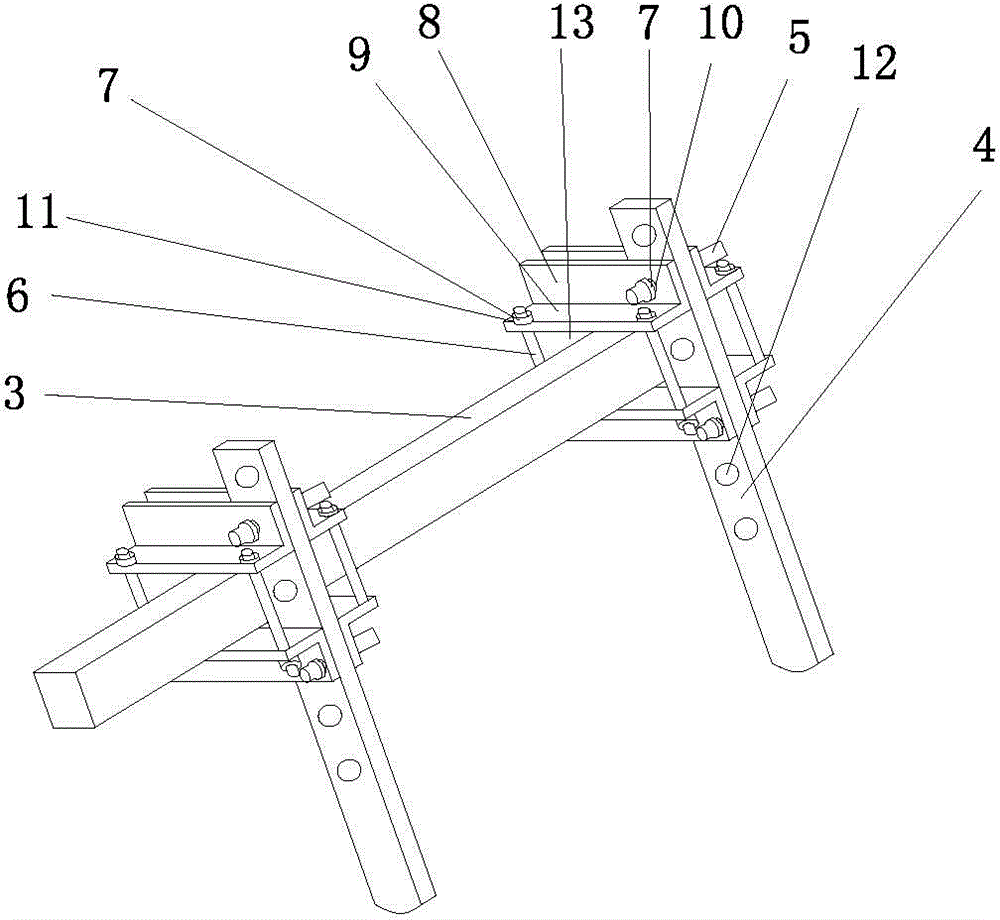

[0016] Depend on Figure 1 to Figure 4 As shown, the present invention comprises vehicle frame 1, and one end of vehicle frame 1 is provided with support 2, and support 2 is provided with powder ridge device 21, is provided with traction frame 3 on powder ridge device 21, is provided with on traction frame 3 Mounting seat mechanism, said mounting seat mechanism includes eight mounting seats, two adjustment rods 4, a first fixed rod 5 and a second fixed rod 6, and a tightening device 7 is provided on the first fixed rod 5 and the second fixed rod 6 , the first fixed rod 5 and the second fixed rod 6 are screw rods, the tightening device 7 is a tightening nut, and four mounting seats are respectively provided on both sides of the traction frame 3, and there are four mounting seats between the four mounting seats. An adjustment rod 4, the mounting seat includes a first mounting plate 8 and a second mounting plate 9, the second mounting plate 9 is arranged on both sides of the trac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com