Rushing washing tower

A washing tower and tower body technology, applied in the field of turbulent washing towers, can solve the problems of small operating flexibility, large footprint of packed towers, and low purification efficiency, and achieve the effects of reducing pressure, reducing investment, and preventing sludge from clogging the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

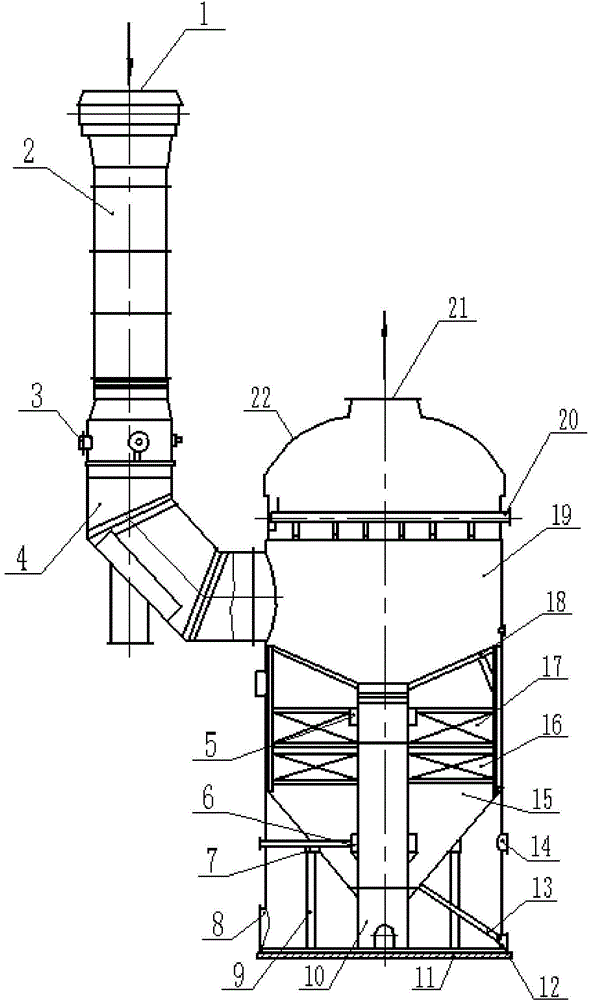

[0017] Examples, see attached figure 1 , a turbulent washing tower, including flue gas inlet 1, transition pipe 2, circulating acid interface 3, reverse nozzle 4, upper overflow weir 5, lower overflow weir 6, annular support 7, circulation tank outlet 8, Pillar 9, central pipe 10, base 11, sewage outlet 12, sewage pipe 13, circulation tank inlet 14, conical settling tank 15, lower inclined plate 16, upper inclined plate 17, liquid collecting pan 18, gas-liquid separation section 19, The circulating acid inlet 20, the flue gas outlet 21 and the tower body 22 are characterized in that the top of the transition pipe 2 is provided with a flue gas inlet 1, and the top of the reverse nozzle 4 is installed on the bottom of the transition pipe 2. The side of the nozzle 4 is provided with a circulating acid interface 3 near the top, the bottom of the reverse nozzle 4 is connected to the gas-liquid separation section 19, the top of the tower body 22 is provided with a flue gas outlet 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com