Dust collecting device on bagged cement truck loading site

A dust collection device and on-site technology, applied in the direction of dust removal, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as polluting the environment and affecting the health of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

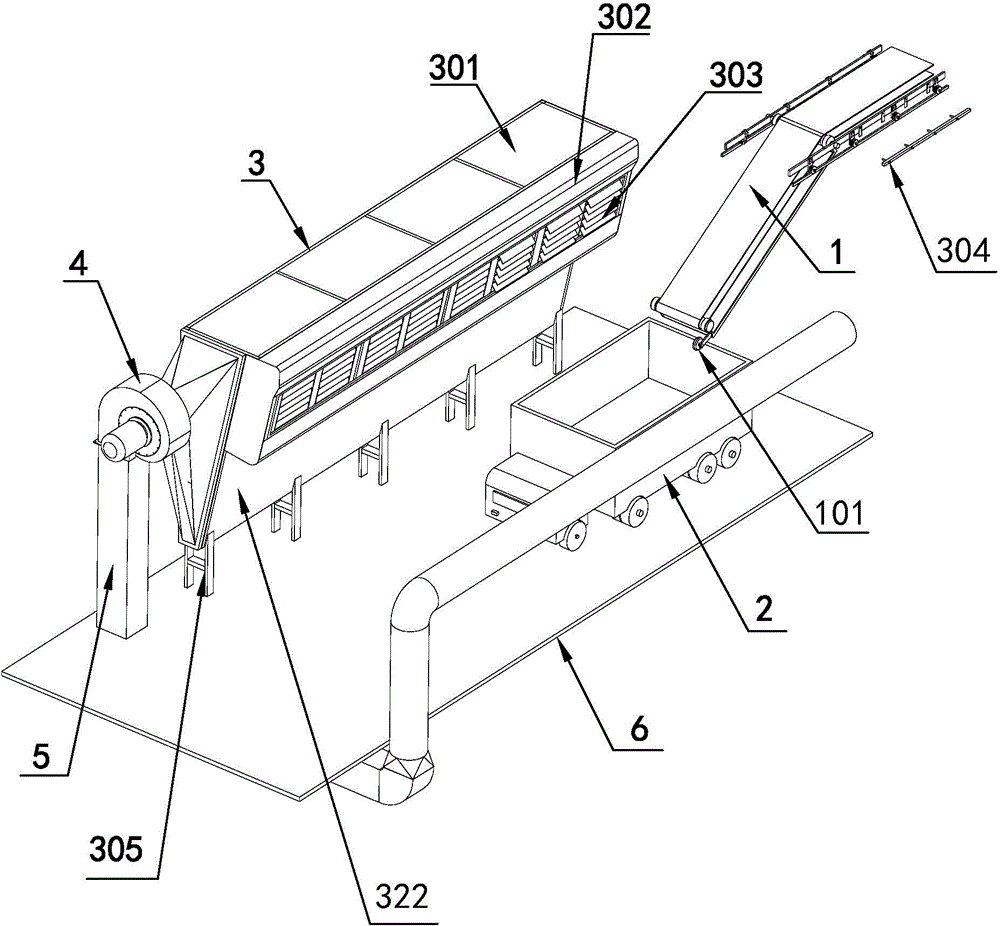

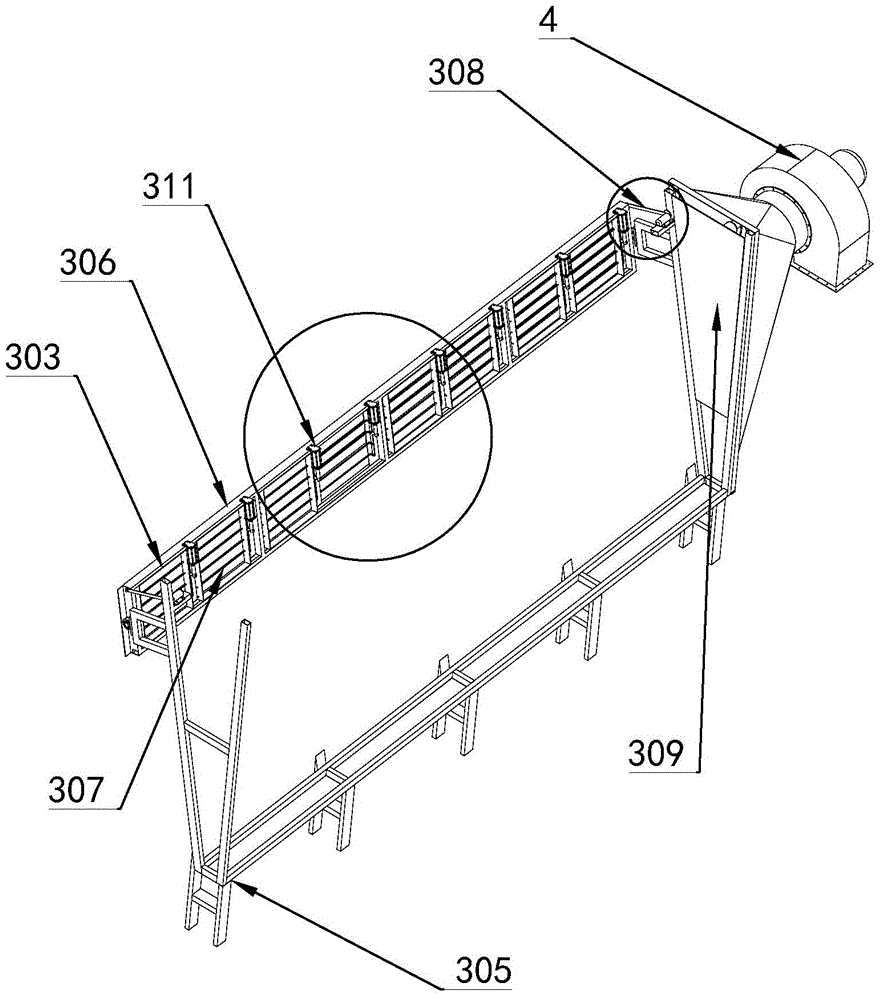

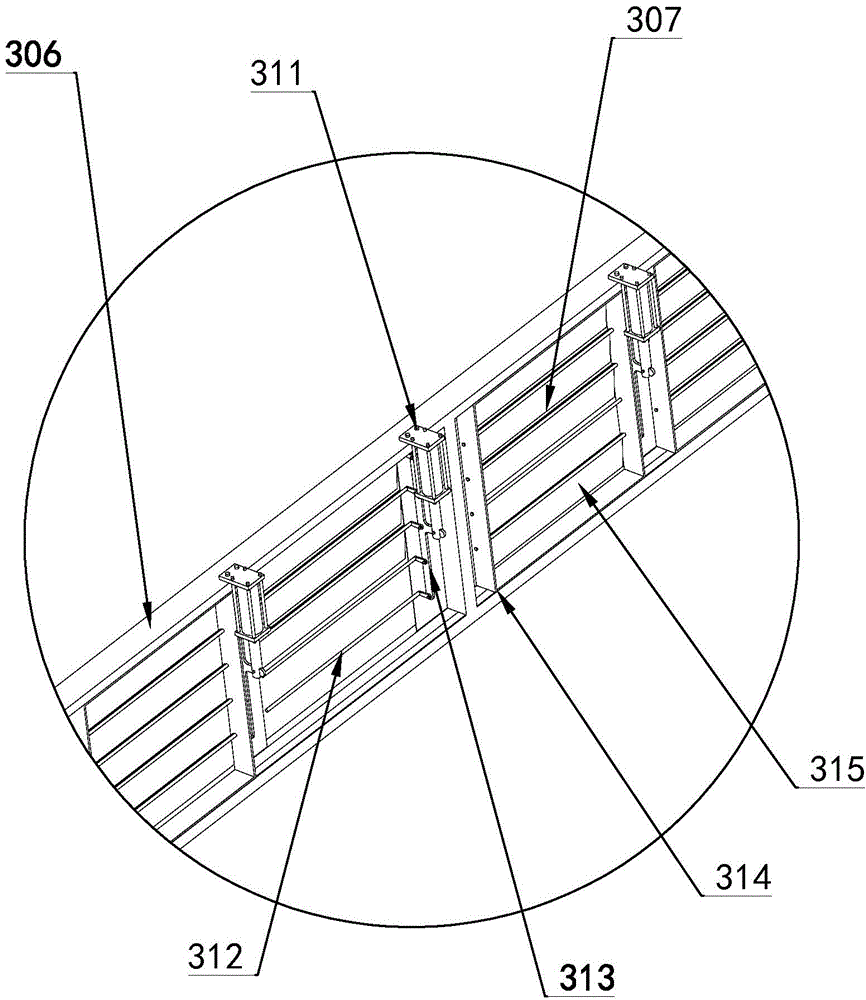

[0022] For the convenience of those skilled in the art to understand, the following in conjunction with the attached Figure 1-5 , to further specifically describe the technical solution of the present invention.

[0023] A bagged cement loading site dust collection device, comprising a dust collection box 3, a fan 4, an exhaust pipe 5 and a fan 101, a belt conveyor 1 is provided on one side of the dust collection box 3, and the belt conveyor 1 A fan 101 is provided on one side; the dust collection box 3 includes a support 305, a box body 301, an air collecting fan device 303, a filter cloth 309, a swing device 308 and a blowback device 310, and the support 305 is fixed on the ground 6, The upper part of the support 305 is provided with a box body 301, and the bottom of the box body 301 is provided with an ash box 322; the top side of the ash box 322 is provided with a canvas cover 302; the middle of the canvas cover 302 is provided with an air collecting fan device 303 The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com