Mobile phone middle frame manufacturing process

A manufacturing process and a technology for the middle frame of a mobile phone, which is applied in the field of metal processing and can solve the problems of low processing cost and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

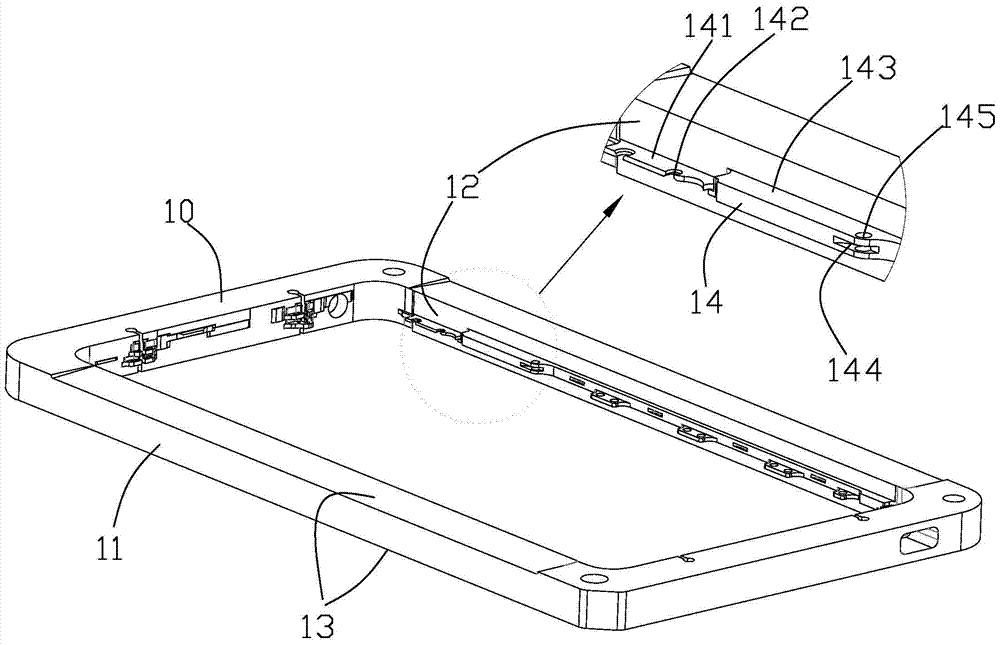

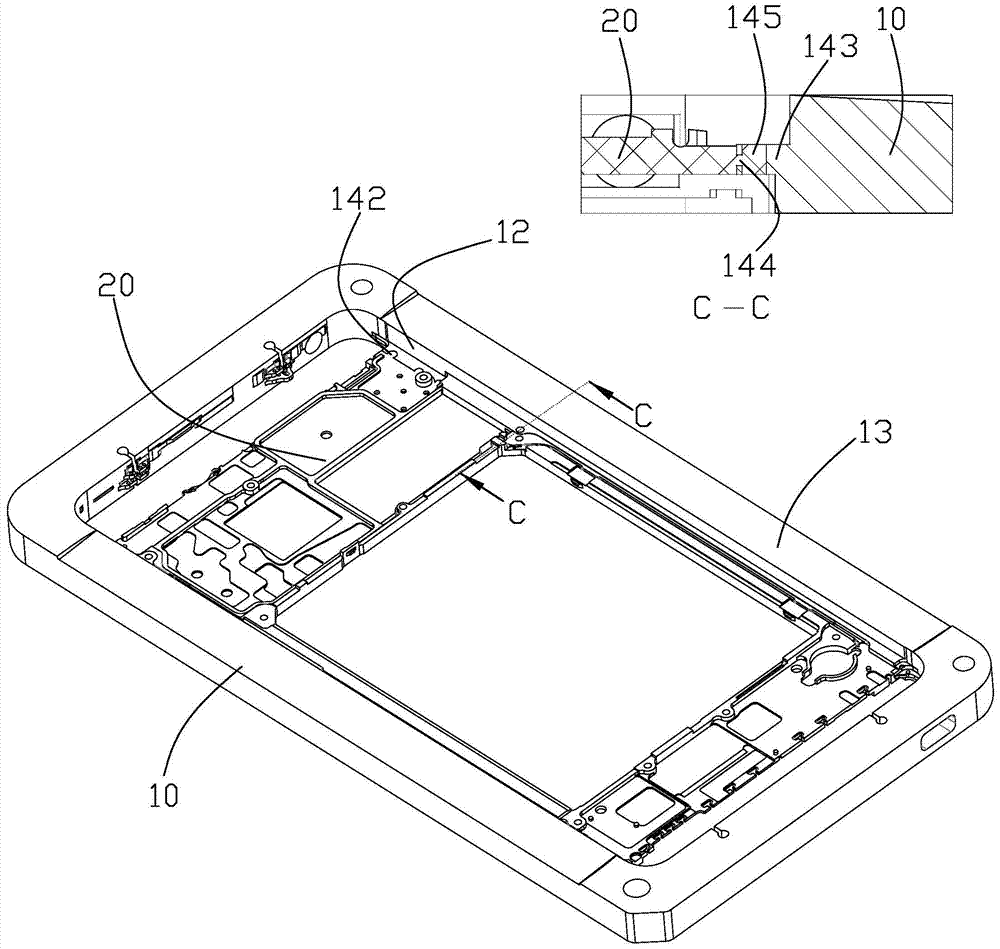

[0021] see figure 1 , figure 2 Shown is the outer frame 10 of the middle frame of the mobile phone that needs to be die-casted. The outer frame 10 is formed by forging or extrusion and processed by CNC. The outer frame 10 does not rule out being processed by other processes.

[0022] The outer frame 10 is approximately a closed rectangular structure, including an outer side 11 , an inner side 12 opposite to the outer side 11 , and upper and lower sides 13 between the inner side 12 and the outer side 11 . The inner surface 12 of the outer frame 10 is inwardly processed to form a protrusion 14, and the protrusion 12 includes a thinner protrusion 141 and a thicker protrusion 143, and the thinner and thicker protrusions 141, 143 The thicknesses are all smaller than the thickness of the outer frame 10 itself. A through hole 142 is formed on the thinner protruding portion 141, and the through hole 142 opens toward the inner side, and a groove-like structure 144 is formed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com