A kind of manufacturing method of automobile seat cushion cover

A production method and a technology of automobile seat cushions, which are applied in the field of weaving and dyeing, can solve the problems of poor riding comfort, easy wear and tear, poor aesthetics and grades, etc., to improve quality, improve quality, and reduce heat loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

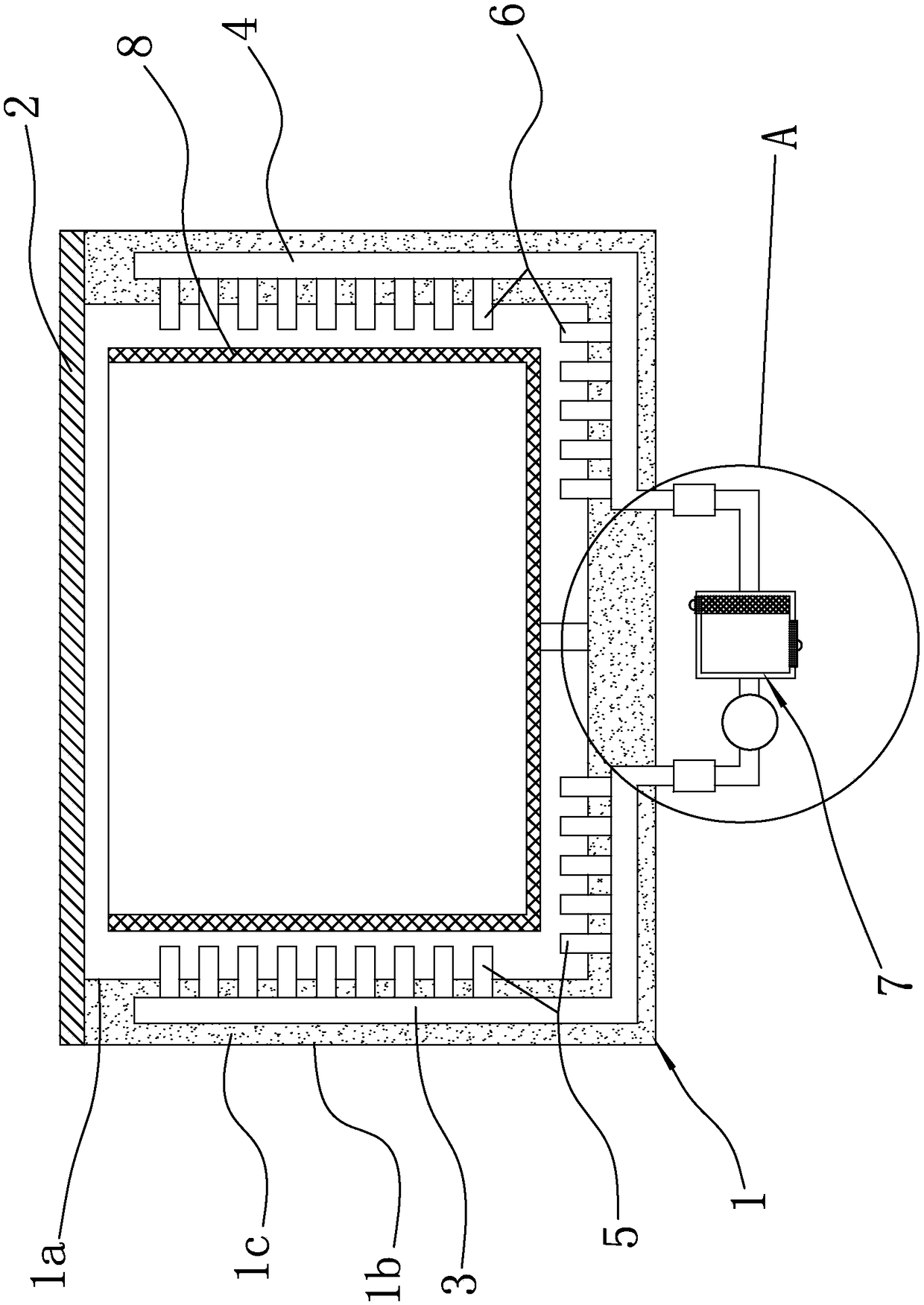

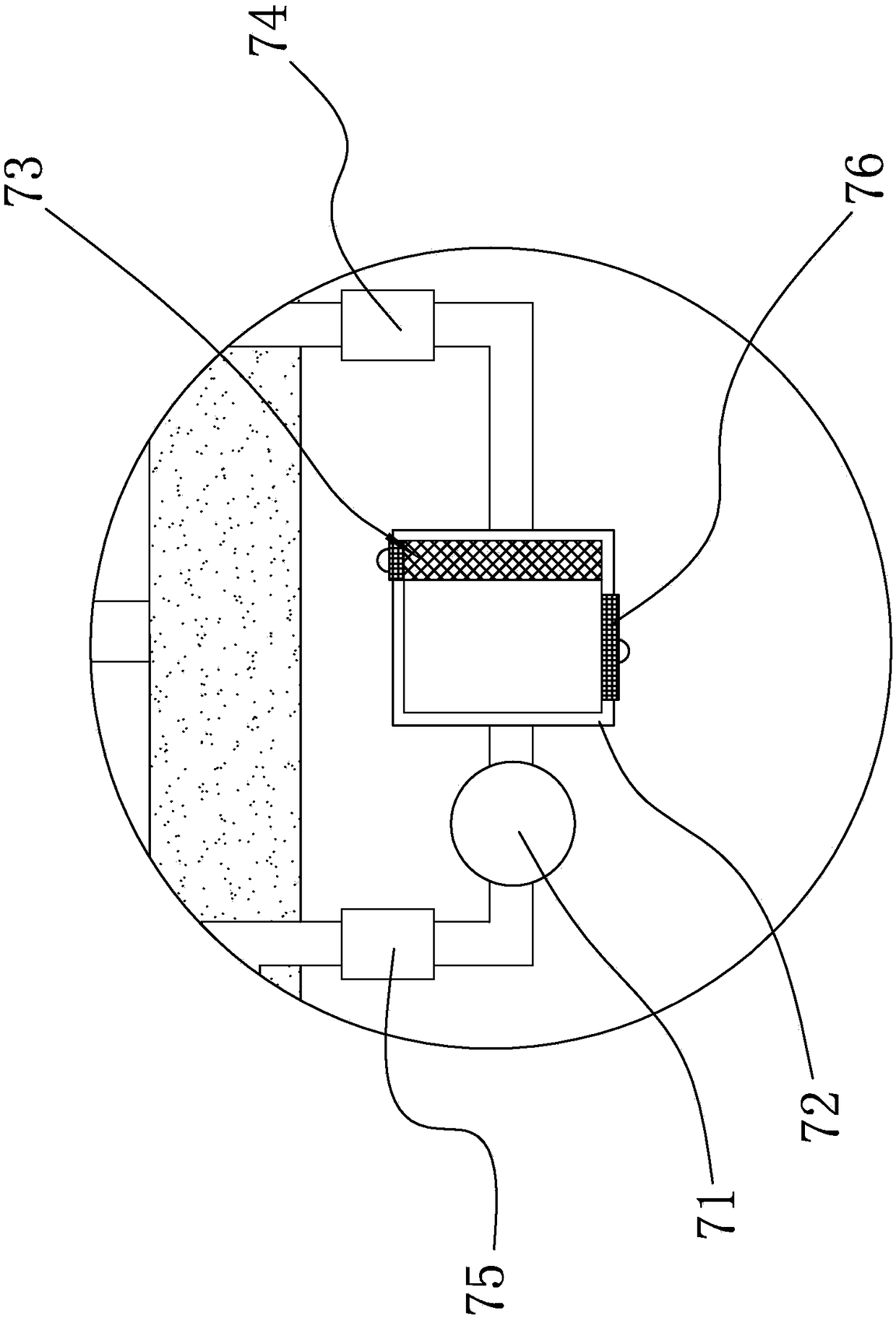

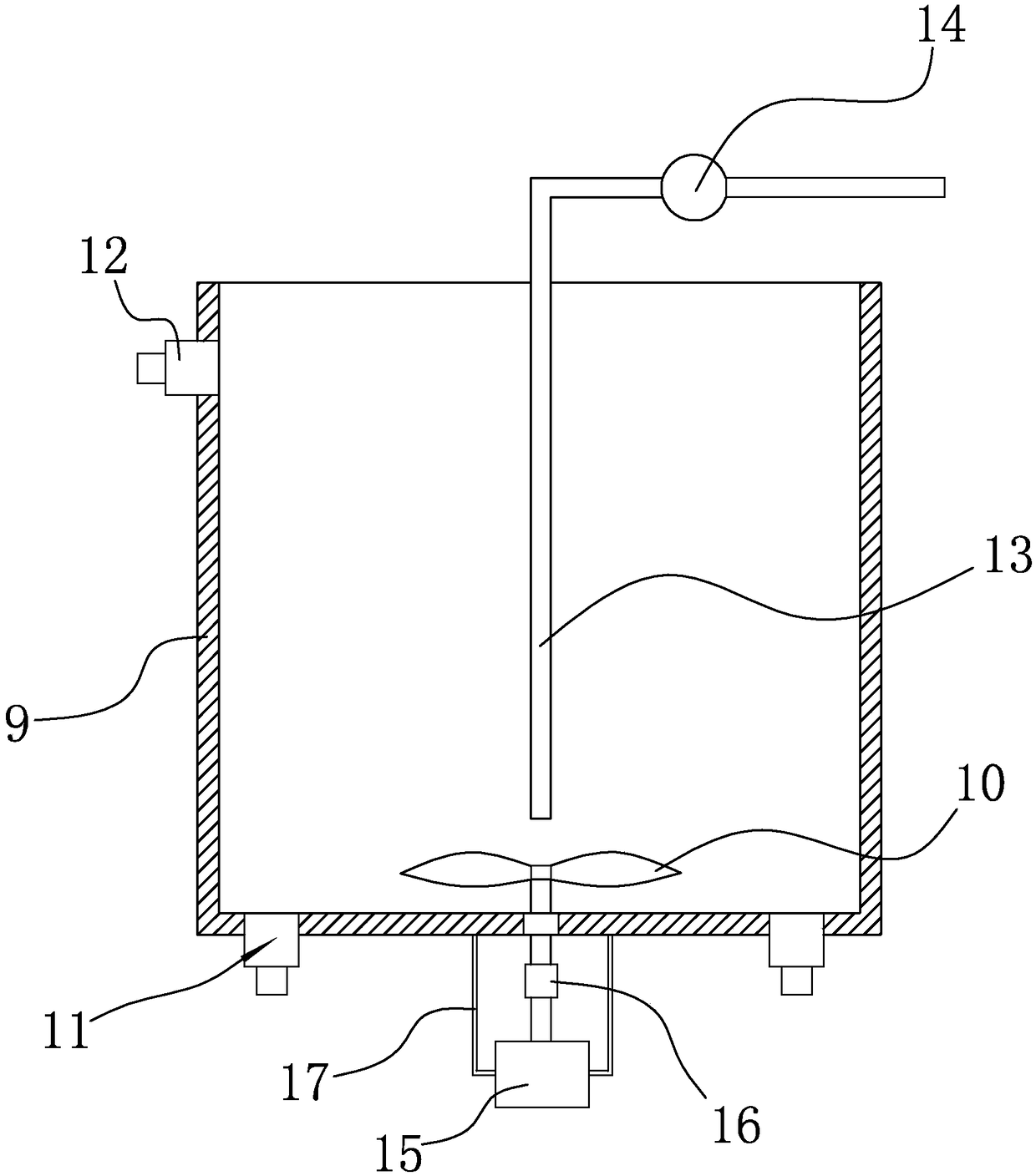

[0032] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0033] A kind of manufacture method of automobile cushion cover, this manufacture method comprises the following steps: a, select base layer fabric; base layer fabric selects PVC film, b, select surface layer fabric; surface layer fabric select flannelette for use; Warp knitted fabric; d, dyeing treatment; prepare a dye vat, add dye solution in the dye vat, put the surface layer fabric and the middle layer fabric into the dye vat for dyeing treatment, and the dye vat is connected with a waste liquid treatment device;

[0034] e. Composite: compound the surface fabric to one side of the middle layer fabric through the compound device; compound the bottom fabric to the other side of the middle layer fabric through the compoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com