Installation tool for airplane thin-wall component, tool manufacturing method and application method

A production method and a technology for installing tooling, applied in the aviation field, can solve problems such as failure to assemble composite material components, extrusion deformation, and difficult parts to fit perfectly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The tip rib of the wing is made of two layers of 92125 fiber cloth, with an average thickness of about 0.6mm. It is difficult to form a perfect fit between ordinary wooden tooling and the root rib of the wing tip, and it is easy to be squeezed and deformed during the gluing process, which makes it difficult to assemble the wing tip and the wing.

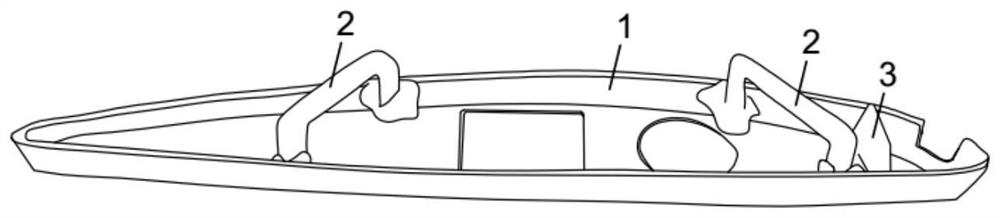

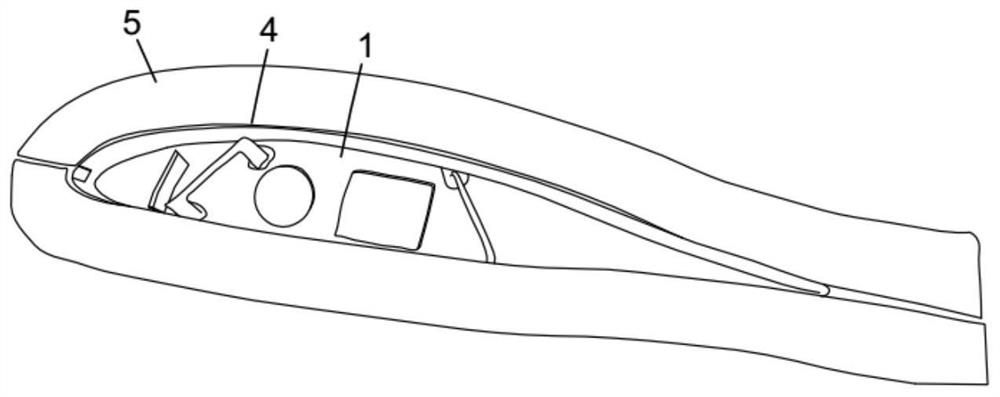

[0025] The invention provides an installation tool for aircraft thin-walled parts, such as figure 1 , including a frock body 1 and a handle insert 2 connected with the frock body, the outer contour of the frock body is copied to the inner surface of the tip rib of the wing. The steps to use the installation tool are as follows:

[0026] Step 1: Glue the corresponding small parts of the wing tip to the lower shell of the wing tip;

[0027] Step 2: Clamp the upper and lower shells of the wing tip;

[0028] Step 3: The worker holds the handle insert 2, presses the tooling body 1 into the inside of the wing tip rib, squeezes ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com