Oil tank truck for mine

A technology for oil tank cars and mines, which is applied to tank cars, transport passenger cars, railway car body parts, etc. It can solve problems such as waste of resources, inability to transport oil, and mutual collision of oil barrels, so as to improve work efficiency, reduce transportation costs, and improve safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

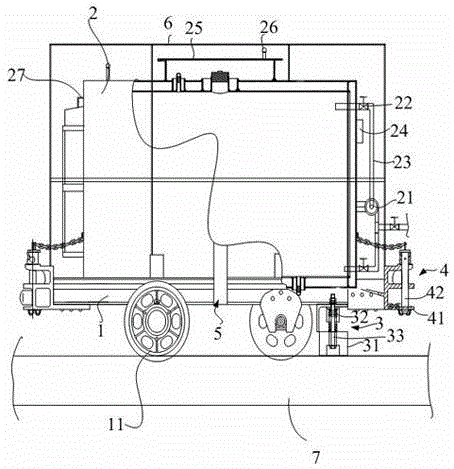

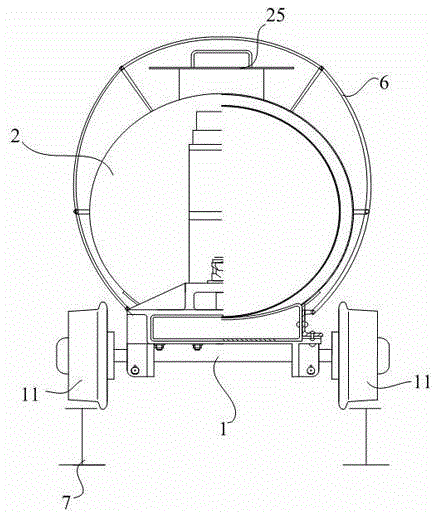

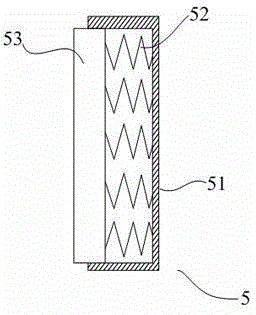

[0026] Example 1, such as figure 1 , figure 2 As shown, the present embodiment provides a kind of oil tank truck for mines, including a chassis 1, and wheels 11 for walking on the guide rail 7 are arranged below the chassis 1 (the style of the wheels and the connection mode between the wheels and the chassis are technical in the art. It is well known to personnel, so it will not be described in detail here), and an oil storage tank 2 is set on the chassis 1 (the oil storage tank is a tank body manufactured according to the national pressure vessel manufacturing standard. Compared with the traditional one, the oil storage tank has a The thickness should be thicker), the size of the oil storage tank 2 should be slightly smaller than the chassis 1, and one end of the chassis 1 is provided with a connecting device 4 for connecting with the tractor (generally, the end connected with the tractor is the front end of the tanker ), an anti-static device 3 is also provided on the chas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com