Glass melting furnace and glass melting method

A glass melting furnace and glass technology, which is applied in glass furnace equipment, glass production, glass manufacturing equipment and other directions, can solve the problems of inability to meet the requirements of glass furnace combustion applications, large waste of inferior fuel, and comprehensive utilization of unfavorable fuels. Glass micro-defects, reduction of regenerator logarithms, and significant energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

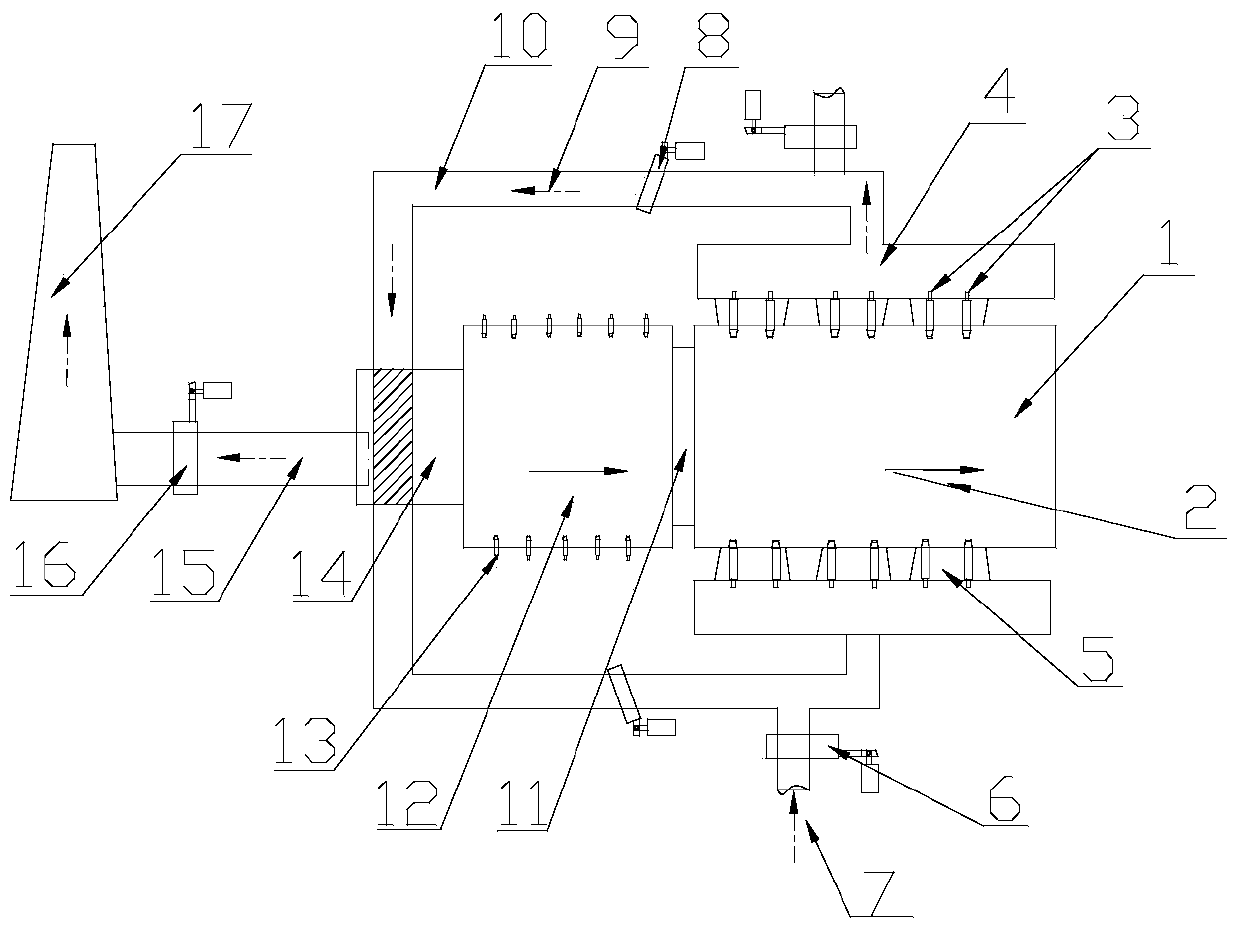

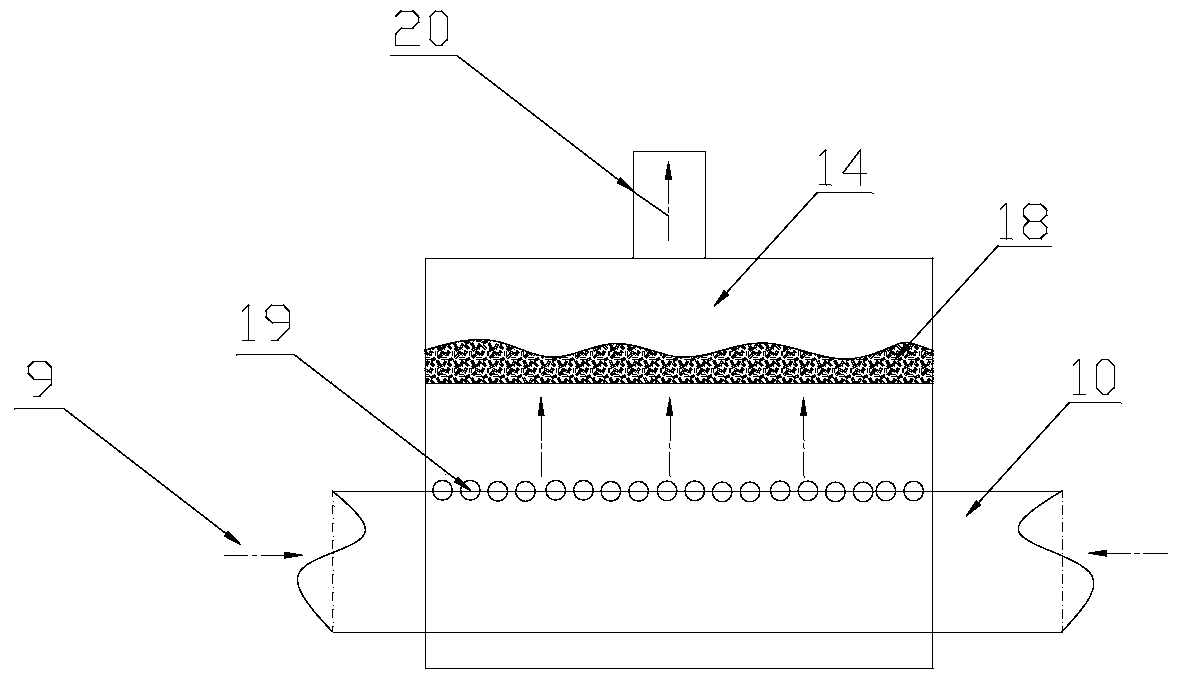

[0024] Melting, clarification, and homogenization in the glass preparation method are the core steps in the glass production process and need to be carried out in a melting furnace. Therefore, the glass melting furnace is the core equipment in the glass production process. The structure of the glass melting furnace directly affects the glass. Production process steps Cost, quality and efficiency of primary glass production. The present invention adopts a two-stage melting process, and the applied equipment is a glass melting furnace including a primary melting pool and a secondary melting pool. The glass raw materials are heated at 700-800°C through the primary melting pool to decompose the carbonate, and then enter The secondary melting pool is heated above 1200°C for subsequent melting, clarification and homogenization process steps. The invention uses low calorific value fuel when heating the primary melting pool, so as to save glass preparation cost and improve energy util...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com