Modified phosphogypsum highway subgrade filler and preparation method thereof

The technology of roadbed filler and phosphogypsum is applied in the field of modified phosphogypsum highway roadbed filler and its preparation. The effect of promoting the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of modified phosphogypsum roadbed filler, comprising the steps of:

[0034] (1) aging phosphogypsum for more than 5 days to obtain material A;

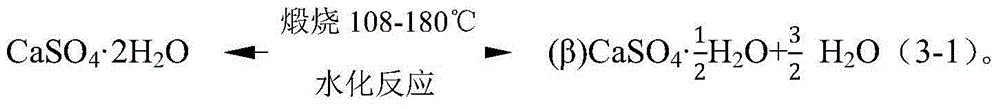

[0035] (2) selecting a part of material A obtained in step (1), and calcining it at 160° C. for 2.5 hours to obtain material B, and then cooling said material B naturally;

[0036] (3) Mix the material A and material B uniformly according to the weight percentage of 91%:9% to obtain material C;

[0037] (4) Add water accounting for 16% of the total weight of the material C to the material C obtained in step (3), and stir evenly to obtain a modified phosphogypsum roadbed filler.

Embodiment 2

[0039] A preparation method of modified phosphogypsum roadbed filler, comprising the steps of:

[0040] (1) aging phosphogypsum for more than 5 days to obtain material A;

[0041] (2) selecting a part of material A obtained in step (1), and calcining it at 200° C. for 1.5 hours to obtain material B, and then cooling said material B naturally;

[0042] (3) Mix the material A and material B uniformly according to the weight percentage of 93%:7% to obtain material C;

[0043] (4) Add water accounting for 12% of the total weight of the material C to the material C obtained in step (3), and stir evenly to obtain a modified phosphogypsum roadbed filler.

Embodiment 3

[0045] A preparation method of modified phosphogypsum roadbed filler, comprising the steps of:

[0046] (1) aging phosphogypsum for more than 5 days to obtain material A;

[0047] (2) selecting a part of material A obtained in step (1), and calcining it at 170° C. for 2 hours to obtain material B, and then cooling said material B naturally;

[0048] (3) Mix the material A and material B uniformly according to the weight percentage of 92%:8% to obtain material C;

[0049] (4) Add water accounting for 13% of the total weight of the material C to the material C obtained in step (3), and stir evenly to obtain a modified phosphogypsum roadbed filler.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com