A method for preparing polymers for western blotting by electric field-assisted removal of template molecules

A technology of western imprinting and template molecules, which is applied in the field of preparation of western imprinting polymers to achieve the effects of high efficiency, reduced production costs, and reduced processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Firstly, according to the prior art, the hemoglobin polymer is made, and then the following steps are carried out:

[0014] a. The hemoglobin polymer is immobilized on the gold electrode as the working electrode, the saturated calomel electrode is used as the reference electrode, and the platinum electrode is used as the counter electrode, and the working electrode, the reference electrode and the counter electrode constitute a three-electrode system;

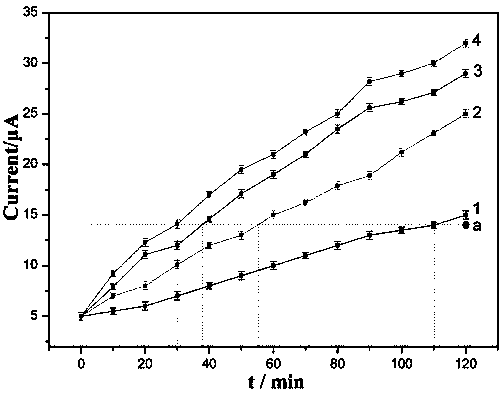

[0015] b. Put the three-electrode system into the protein polymer template molecular elution solution composed of 10% (v / v) acetic acid and 10% (v / v) sodium lauryl sulfate solution, because the elution solution The pH value is lower than the isoelectric point of hemoglobin, so apply potentials of 0.1V, 0.4V, 0.7V and 1.0V between the working electrode and the reference electrode, and elute for 30-120min respectively to obtain the hemoglobin imprinted polymer;

[0016] c. Dry the obtained hemoglobin-imprinted polymer unde...

Embodiment 2

[0023] First, according to the prior art, the myoglobin polymer is made, and then the following steps are carried out:

[0024] a. The myoglobin polymer is immobilized on the graphite electrode as the working electrode, the mercurous sulfate electrode is used as the reference electrode, and the carbon electrode is used as the counter electrode, and the working electrode, the reference electrode and the counter electrode constitute a three-electrode system;

[0025] b. Put the three-electrode system into the phosphate buffer solution of pH 9.0 (protein polymer template molecule elution solution), because the pH value of the elution solution is higher than the isoelectric point of myoglobin, so between the working electrode and the A potential of -1.0V was applied between the reference electrodes for 30 minutes to obtain a myoglobin imprinted polymer;

[0026] c. Dry the obtained myoglobin-imprinted polymer under nitrogen gas to obtain completely eluted myoglobin-imprinted polym...

Embodiment 3

[0028] First, according to the prior art, the myoglobin polymer is made, and then the following steps are carried out:

[0029] a. The myoglobin polymer is immobilized on the silver electrode as the working electrode, the calomel electrode is used as the reference electrode, and the platinum electrode is used as the counter electrode, and the working electrode, the reference electrode and the counter electrode constitute a three-electrode system;

[0030] b. Then put the three-electrode system into the phosphate buffer solution (elution solution of protein polymer template molecules) with pH 10.0. A potential of -1.0V was applied between the reference electrodes for 120min to obtain a myoglobin imprinted polymer;

[0031] c. Dry the obtained myoglobin-imprinted polymer under nitrogen gas to obtain completely eluted myoglobin-imprinted polymer.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap