A kind of preparation method of near ultraviolet fluorescent powder strontium europium pyrophosphate

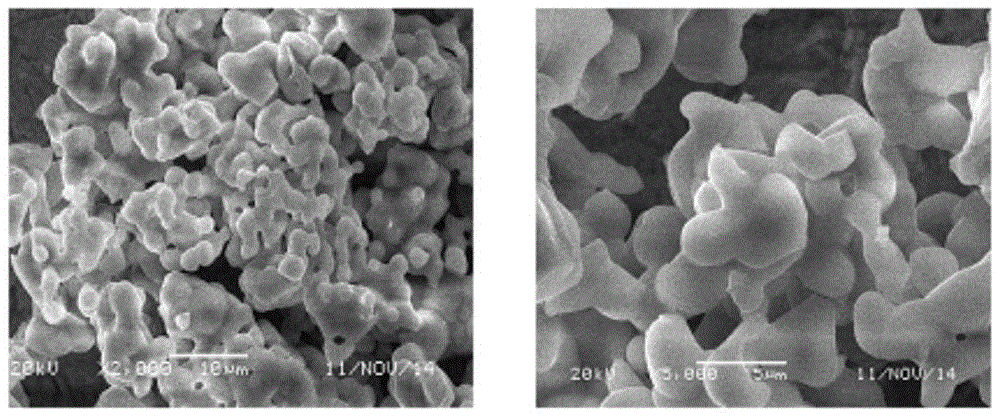

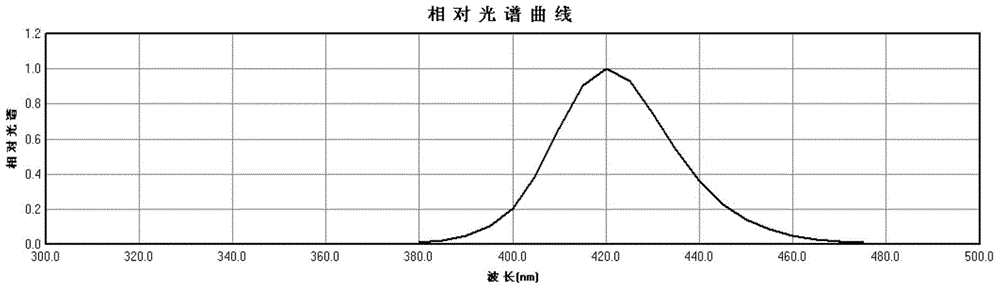

A technology of strontium europium pyrophosphate and phosphor powder, applied in chemical instruments and methods, luminescent materials, etc., can solve the problem of uneven mixing, and achieve the effects of high radiation flux and excellent powder particle morphology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A preparation method of near-ultraviolet fluorescent powder strontium europium pyrophosphate, comprising the following steps:

[0027] Step 1, Oxidation of the Matrix Material

[0028] Weigh a certain mass of matrix material strontium hydrogen phosphate (SrHPO) 4 ) into an open alumina crucible, put into a muffle furnace, oxidize and burn at 680 ℃-900 ℃ for more than 3 hours, and cool to room temperature;

[0029] Step 2, Intermediate Processing

[0030] The matrix material strontium hydrogen phosphate (SrHPO 4 ) into a polyethylene plastic bottle, then press strontium hydrogen phosphate (SrHPO 4 ): ball: water is dispersed according to the mass ratio of 1:2:2, the dispersion speed is 20-50 rpm, the dispersion time is 3-6 hours, and then the dispersed strontium hydrogen phosphate (SrHPO 4 ) through a 300-600 mesh water sieve, and then pass the strontium hydrogen phosphate (SrHPO 4 ) powder was washed with water under the following conditions, strontium hydrogen pho...

Embodiment 1

[0041] Step 1, Oxidation of the Matrix Material

[0042] Weigh the matrix material strontium hydrogen phosphate (SrHPO 4 ) 500g, put into open alumina crucible, put into muffle furnace, temperature 680 ℃, oxidative burning for 4 hours, cooled to room temperature;

[0043] Step 2, Intermediate Processing

[0044] The matrix material strontium hydrogen phosphate (SrHPO 4 ) into a polyethylene plastic bottle, then press strontium hydrogen phosphate (SrHPO 4 ): ball: water is dispersed in a mass ratio of 1:2:2, the dispersion speed is 30 rpm, and the dispersion time is 6 hours, and then the dispersed strontium hydrogen phosphate (SrHPO 4 ) through a 300-mesh water sieve, and then the strontium hydrogen phosphate (SrHPO 4 ) powder was washed with water under the following conditions, strontium hydrogen phosphate (SrHPO 4 ) powder: the water is 1:10 by mass ratio, the water temperature is 80 ℃, washed with water for more than 3 times, the water content in the powder after the w...

Embodiment 2

[0053] Step 1, Oxidation of the Matrix Material

[0054] Weigh the matrix material strontium hydrogen phosphate (SrHPO 4 ) 700g, put into open alumina crucible, put into muffle furnace, temperature 800 ℃, oxidative burning for 4 hours, cooled to room temperature;

[0055] Step 2, Intermediate Processing

[0056] The matrix material strontium hydrogen phosphate (SrHPO 4 ) into a polyethylene plastic bottle, then press strontium hydrogen phosphate (SrHPO 4 ): ball: water is dispersed in a mass ratio of 1:2:2, the dispersion speed is 35 rpm, and the dispersion time is 5 hours, and then the dispersed strontium hydrogen phosphate (SrHPO 4 ) through a 300-mesh water sieve, and then the strontium hydrogen phosphate (SrHPO 4 ) powder was washed with water under the following conditions, strontium hydrogen phosphate (SrHPO 4 ) Powder: the water is 1:10 by mass ratio, the water temperature is 80 ° C, and the water is washed for more than 3 times, and the water content in the powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com