A kind of preparation method of spherical nanometer yttrium oxide powder for ultraviolet lamp tube

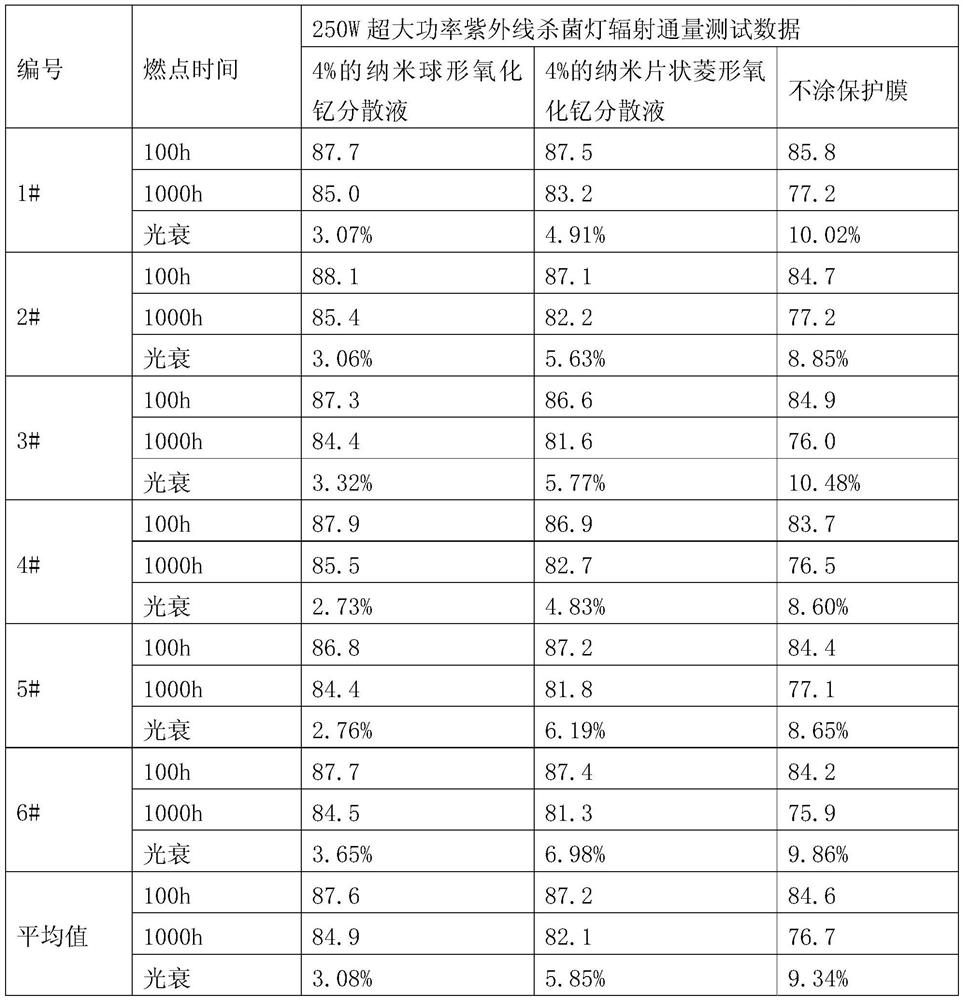

A technology of nanometer yttrium oxide and production method, which is applied in the direction of preparation/treatment of yttrium oxide/yttrium hydroxide, rare earth metal compounds, rare earth metal oxide/hydroxide, etc., which can solve the problem of weak ability of dense bonding and blocking ultraviolet rays Radiation penetration, use effect decline and other problems, to achieve the effect of low light attenuation and high radiant flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0024] The preparation method of the spherical nanometer yttrium oxide powder used for the ultraviolet lamp comprises the following steps:

[0025] Step 1, mixing the yttrium oxide of the nanoscale flaky rhomboid powder and deionized water together, and stirring rapidly for 30 to 60 minutes, to prepare the first mixed solution;

[0026] Among them, the mass ratio of yttrium oxide to deionized water in the nanoscale flaky rhomboid powder is 1-11:92-101;

[0027] Step 2, mixing ethanolamine and ethyl acetoacetate together, stirring at a constant speed for 5 to 15 minutes, and preparing the first dropwise solution;

[0028] Wherein, the volume ratio of ethanolamine to ethyl acetoacetate is 1:0.95~1.15;

[0029] Step 3, mixing boric acid and glacial acetic acid together, stirring at a constant speed for 15 to 30 minutes, and preparing the second dropwise solution;

[0030] Wherein, the mass ratio of boric acid and glacial acetic acid is 1:0.95~1.15;

[0031] Step 4, adding the ...

no. 2 example

[0051] In this embodiment, the mass ratio of yttrium oxide to deionized water in the nanoscale flake rhomboid powder is 3:92. The volume ratio of ethanolamine to ethyl acetoacetate is 1:0.98. The mass ratio of boric acid to glacial acetic acid is 1:1.08. The mass ratio of the first dropping liquid, the second dropping liquid and the first mixed liquid is 15:35:78.

[0052] Refer to the first embodiment for the rest of the undescribed parts, and will not repeat them here.

no. 3 example

[0054] In this embodiment, the mass ratio of yttrium oxide to deionized water in the nanoscale flaky rhomboid powder is 2:99. The volume ratio of ethanolamine to ethyl acetoacetate is 1:1.07. The mass ratio of boric acid to glacial acetic acid is 1:1.12. The mass ratio of the first dropping liquid, the second dropping liquid and the first mixed liquid is 11:30:78.

[0055] Refer to the first embodiment for the rest of the undescribed parts, and will not repeat them here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com