High-strength WC-ZrO2-Si nano-coating material and preparation method thereof

A wc-zro2-si, nano-coating technology, applied in the direction of coating, metal material coating process, melt spraying, etc., can solve the problems of low hardness and poor wear resistance of the coating, and achieve high hardness and wear resistance. The effect of good performance and excellent anti-abrasive wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

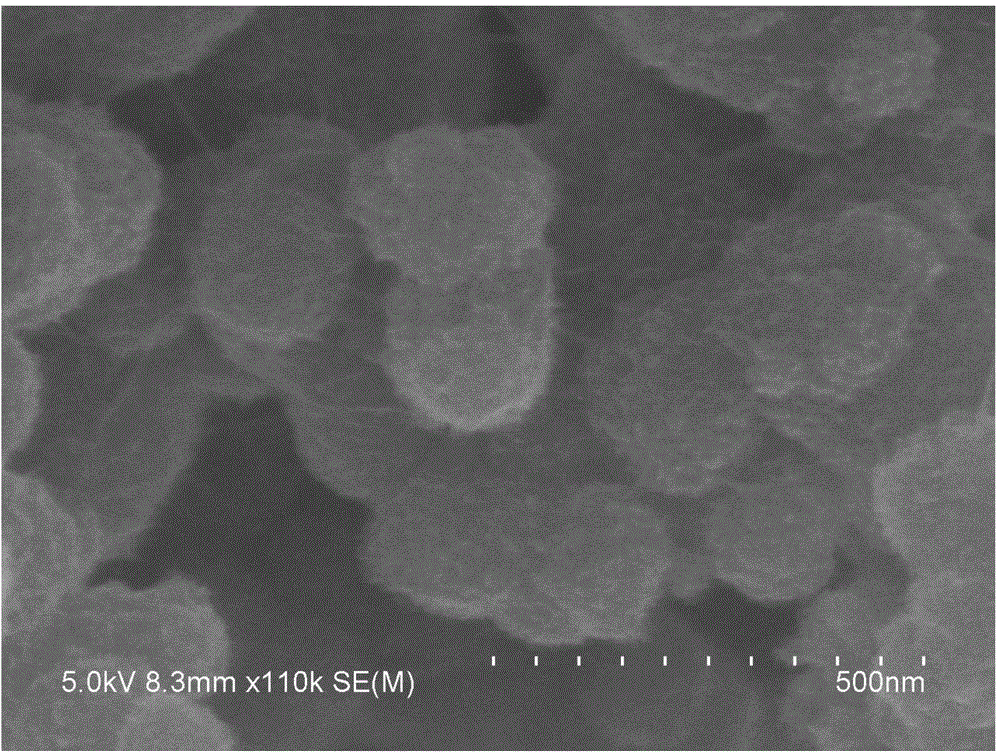

Image

Examples

Embodiment 1

[0020] High strength WC-ZrO 2 -Si nano-coating material, its components and the mass percentage of each component are WC accounts for 75.04%, ZrO 2 Accounted for 11%, Si accounted for 13%, trace elements accounted for 0.96%.

[0021] The trace elements include Cr, Mn and B.

[0022] High strength WC-ZrO 2 -The preparation method of Si nano coating material, comprises the following steps:

[0023] (1) First, WC-ZrO was prepared by gas atomization method 2 - nanospheres of Si;

[0024] (2) The nanospheres prepared in step (1) are mixed with Cr, Mn, B to obtain nanopowder by active agent protection method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com