Stirrer blade and preparation method of the stirrer blade

A mixer and blade technology, which is applied in the field of mixer blade and mixer blade preparation, can solve the problems of reducing the wear rate and failing to achieve the balance of blade toughness and hardness, and achieve good anti-abrasive wear and excellent anti-abrasive wear performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

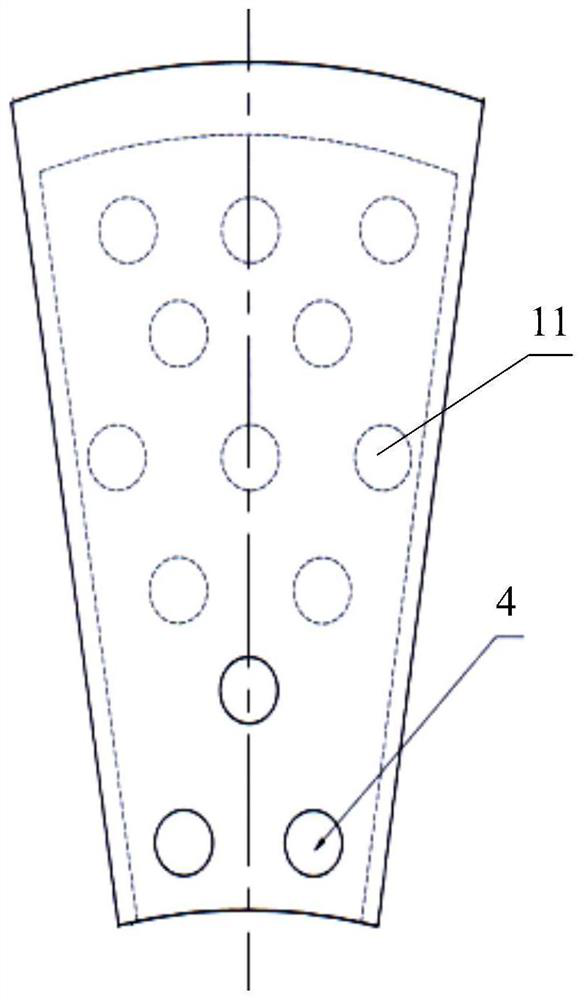

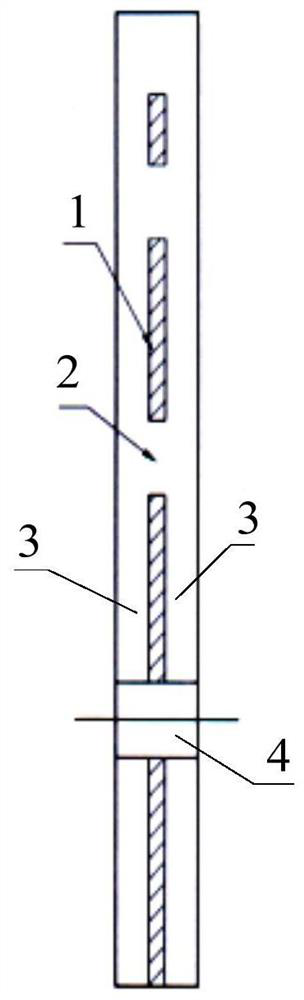

[0048] see figure 1 and figure 2 As shown, the embodiment of the present application provides a mixer blade, including: a tough matrix 1, a wear-resistant part 2 and a wear-resistant layer 3;

[0049] Wherein, the tough matrix 1 is formed with a plurality of forming holes 11, and the wear-resistant part 2 is arranged in the forming holes 11. Specifically, in this embodiment, the tough matrix 1 is a kind of orifice plate. Of course, it is not limited thereto. Actual need to set;

[0050] The wear-resistant layer 3 covers the surfaces of the tough substrate 1 and the wear-resistant portion 2 .

[0051]From the structure described above, it can be seen that the wear-resistant part 2 and the wear-resistant layer 3 have a certain hardness, that is, they have good wear resistance, and the tough matrix 1 has a certain toughness, and its toughness is used to make up for the wear-resistant part 2 and the wear-resistant layer. The brittleness of the grinding layer 3 achieves complem...

Embodiment 2

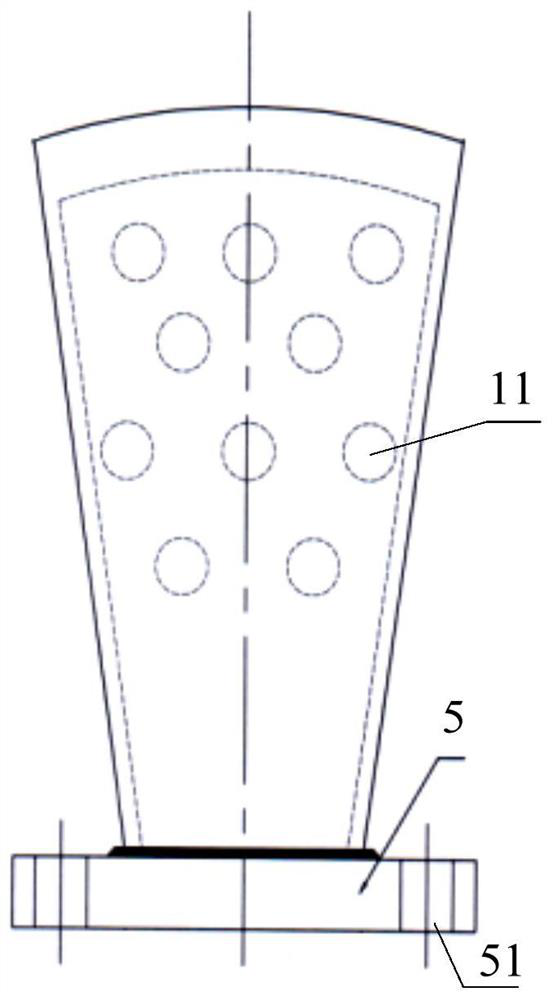

[0068] see image 3 and Figure 4 As shown, the mixer blade in this embodiment is an improvement on the basis of Embodiment 1. The technical content disclosed in Embodiment 1 will not be described repeatedly, and the content disclosed in Embodiment 1 also belongs to the content disclosed in this embodiment.

[0069] The difference between the technical solution disclosed in this embodiment and the technical solution disclosed in Embodiment 1 is as follows:

[0070] The tough matrix 1 has a fan-shaped plate structure, and the inner ring edge of the fan-shaped plate structure near the center of the circle is linear, and the outer ring edge of the fan-shaped plate structure away from the center of the circle is arc-shaped;

[0071] The linear inner ring edge of the fan-shaped plate structure is connected with a linear plate-shaped base 5 along the height direction of the toughness matrix 1. The base 5 is provided with an installation through hole 51. Specifically, the base 5 is ...

Embodiment 3

[0075] see Figure 5 to Figure 7 As shown, the mixer blade in this embodiment is an improvement on the basis of Embodiment 1. The technical content disclosed in Embodiment 1 will not be described repeatedly, and the content disclosed in Embodiment 1 also belongs to the content disclosed in this embodiment.

[0076] The difference between the technical solution disclosed in this embodiment and the technical solution disclosed in Embodiment 1 is as follows:

[0077] The tough matrix 1 has a fan-shaped plate structure, and the inner ring edge close to the center of the circle and the outer ring edge far away from the center of the circle of the fan-shaped plate structure are arc-shaped;

[0078] The arc-shaped inner ring edge of the fan-shaped plate structure is connected with a base 5 with an arc-shaped cross-section along the height direction of the tough matrix 1. The base 5 is provided with a mounting through hole 51. Specifically, the base 5 is installed on the rotating shaf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact toughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com