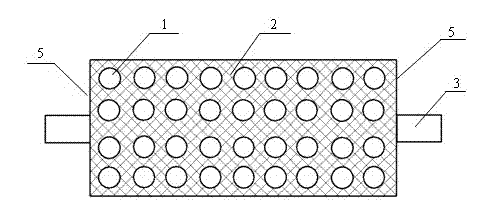

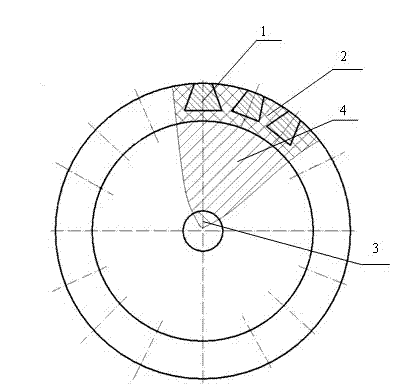

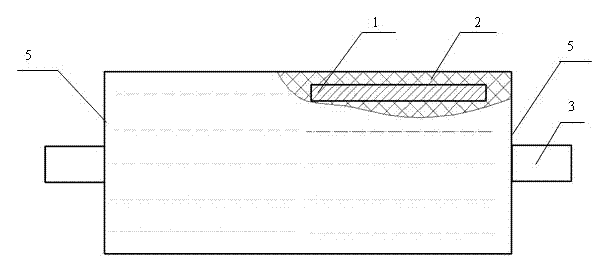

Rubber-coating roll with composite rubber-coating layer and method for preparing same

A composite material layer and composite material technology, applied in the field of rubber-coated rollers and their preparation, can solve problems such as poor impact resistance, and achieve the effects of good toughness and plasticity, excellent wear resistance and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Prepare the rotary body, which has a diameter of 100 mm and a length of 2 m. It is a solid structure. The material is Q345 steel, and the rotary body is processed by the existing turning method. Grooves are machined on the side of the rotor using the existing turning technology. The depth of the groove is 1.0mm, the width is 4mm, and the distance between two adjacent grooves is 8mm. The shape of the groove cross section is rectangular. The groove and the rotor The included angle of the cross-section is 0°, remove the impurities and dirt on the surface of the rotating body, then clean the surface with gasoline, and dry it naturally for 10 minutes after cleaning;

[0044] (2) On the surface of the rotator prepared in step (1), evenly coat polyisocyanate adhesive, and apply it twice, and cool it at room temperature for 25 minutes after each coat, and the total thickness of the adhesive coating is 50mm;

[0045] (3) Preparation of wear-resistant alloy block The wear-res...

Embodiment 2

[0051] (1) Prepare the rotary body. The rotary body is made of a steel pipe with a diameter of 200mm, a length of 1m, and a wall thickness of 20mm. The material is Q235 steel. According to the existing sandblasting process, impurities and dirt on the surface of the rotary body are removed, and then use Gasoline cleaning, cleaning and drying with a fan;

[0052] (2) On the surface of the rotor prepared in step (1), evenly coat the epoxy resin adhesive twice, and cool it at room temperature for 20 minutes after each coat, and the total thickness of the adhesive coating is 30mm ;

[0053] (3) Preparation of wear-resistant alloy block

[0054] The wear-resistant alloy block blank is prepared by using the existing cold drawing technology. The blank is a wire rod with a diameter of 10mm, which is cut into a cylinder with a length of 140mm after straightening. The material of the wear-resistant alloy block 1 is ordinary low and medium alloy steel, and its chemical composition (mass...

Embodiment 3

[0060] (1) Prepare the rotary body. The rotary body is made of a steel pipe with a diameter of 400mm, a length of 1500mm, and a wall thickness of 25mm. The material is Q195 steel. According to the existing sandblasting process, remove impurities and dirt on the surface of the rotary body, and then use Gasoline cleaning, cleaning and drying with a fan;

[0061] (2) Preparation of wear-resistant alloy block

[0062] The wear-resistant alloy block is prepared by the existing powder metallurgy technology. The geometry of the wear-resistant alloy block 1 is a regular square prism. The lower bottom of the regular square pedestal is a square with a side length of 12 mm, the upper bottom is a square with a side length of 8 mm, and a height of 6 mm. . The wear-resistant alloy block 1 is made of high-speed steel, and its chemical composition (mass percentage) is 0.9%C, 4.1%Cr, 1.2%V, 18.0%W, and the balance is Fe;

[0063] The surface of the prepared wear-resistant alloy block is trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com