Metal membrane containing metal membranes containing metal membranes with etching solution

A technology of composition and etching solution, which is applied in the field of etching solution composition for metal film, and can solve problems such as etching speed delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 5 and comparative example 1

[0058] Examples 1 to 5 and Comparative Example 1. Manufacture of Etching Solution Composition for Metal Film

[0059] The etching liquid composition for metal films was manufactured using the components and content shown in Table 1 below.

[0060] The unit of content of each component in the following Table 1 is weight %, and the balance is water.

[0061] 【Table 1】

[0062] distinguish

APS

AF

HNO 3

ATZ

p-TSA

A.A.

AcOH

h 3 PO 3

Example 1

15

0.7

3

1.2

3.0

2.5

8.0

0.5

Example 2

15

0.7

3

1.2

3.0

2.5

8.0

0.8

Example 3

15

0.7

3

1.2

3.0

2.5

8.0

1.0

Example 4

15

0.7

3

1.2

3.0

2.5

8.0

1.2

Example 5

15

0.7

3

1.2

3.0

2.5

8.0

1.5

Comparative example 1

15

0.7

3

1.2

3.0

2.5

8.0

0

[0063] APS: Ammonium persulfate

[006...

experiment example 1

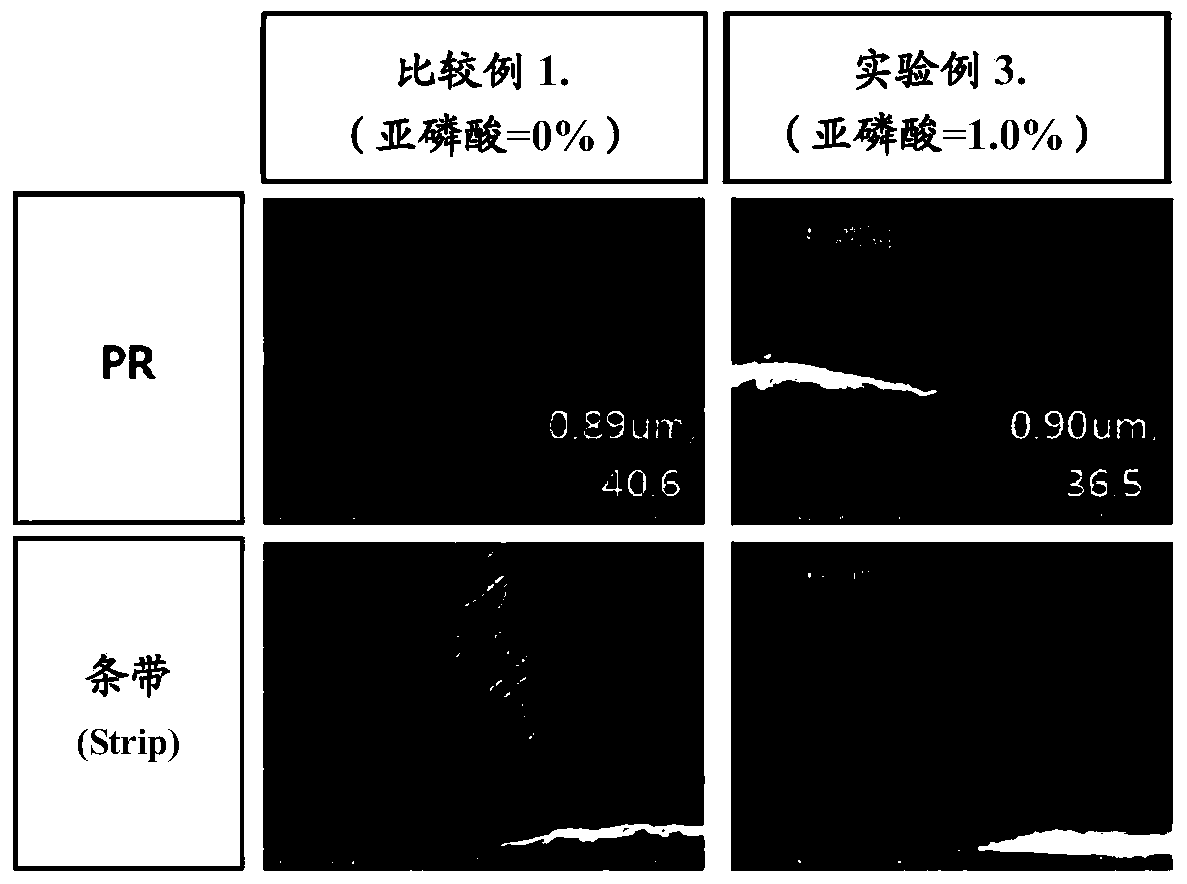

[0069] Experimental example 1. Measurement of etching rate and etching gradient

[0070] The experimental equipment of the spray etching method used a 0.5-generation etcher (Etcher) (AST Company). When performing the etching process, the temperature of the etching solution composition was about 26° C., and the etching time was about 100 to 130 seconds.

[0071] When measuring the cross-section of the etched copper-based double film in the above-mentioned etching process, the cross-section SEM (Hitachi (Hitachi) company product, model name S-4700) was used to measure, and in the following Table 2 and figure 1 The results are shown in .

[0072] 【Table 2】

[0073]

[0074] Such as figure 1 As shown in Table 2, it was confirmed that the etchant composition for a metal film containing phosphorous acid can adjust the inclination of the etching slope without delaying the etching rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com