Foundation grouting method for offshore wind power and foundation grouting work barge for offshore wind power

A technology for foundation grouting and offshore wind power, which is applied to foundation structure engineering, barges/flat-bottomed boats, buildings, etc., and can solve problems that are complex, affect progress, and the foundation cannot be put into use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

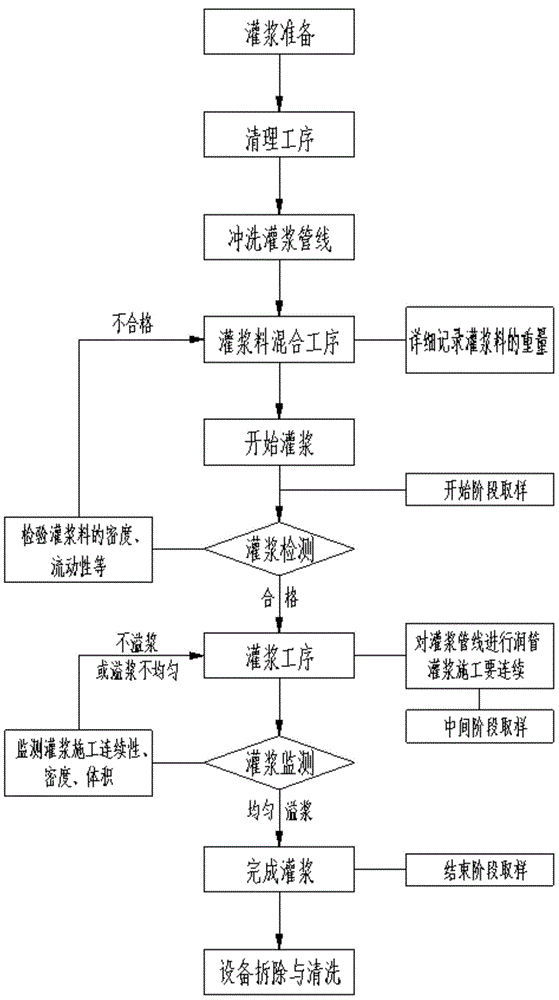

Method used

Image

Examples

Embodiment Construction

[0049] Embodiments of the present invention are described in detail below:

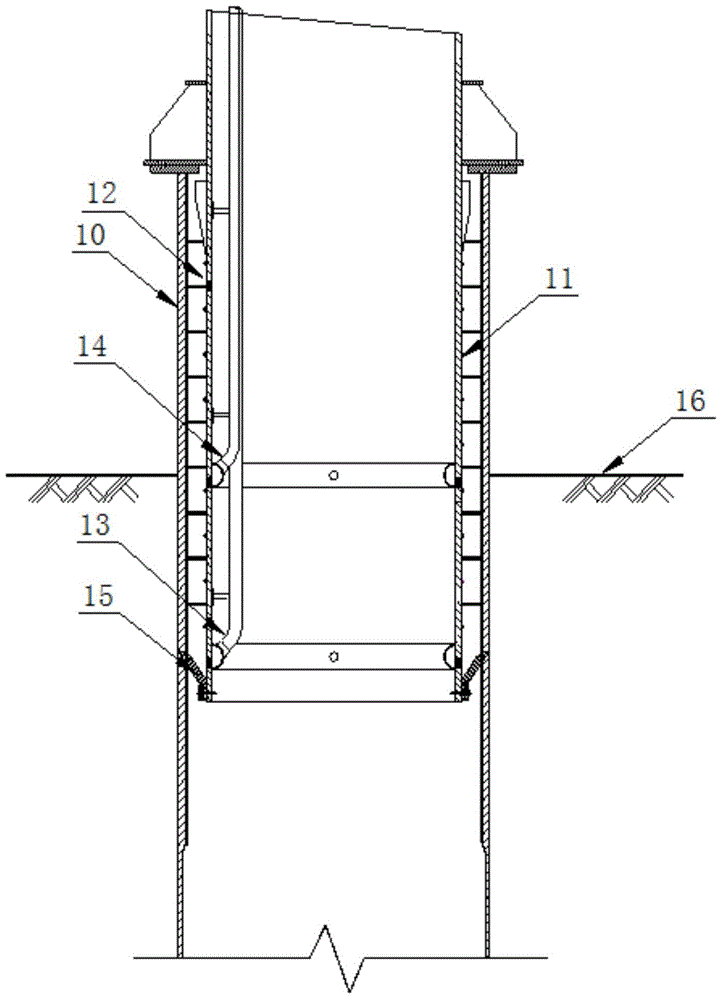

[0050] like figure 1 As shown, this embodiment is illustrated with a typical offshore wind power infrastructure structure, which includes a grouting outer pipe 10 and a grouting inner pipe 11, the grouting outer pipe 10 is inserted under the mud surface 16, and the grouting inner pipe 11 One end of the grouting outer pipe 10 extends into the grouting inner pipe 11. The outer wall of the grouting inner pipe 11 and the inner wall of the grouting outer pipe 10 form a ring-shaped grouting channel 12. The sealing ring 15 that blocks the grouting channel 12 is filled with grouting liquid into the grouting channel 12 through the main grouting pipeline 13 and the secondary grouting pipeline 14 to achieve the purpose of connecting the grouting outer pipe 10 and the grouting inner pipe 11 .

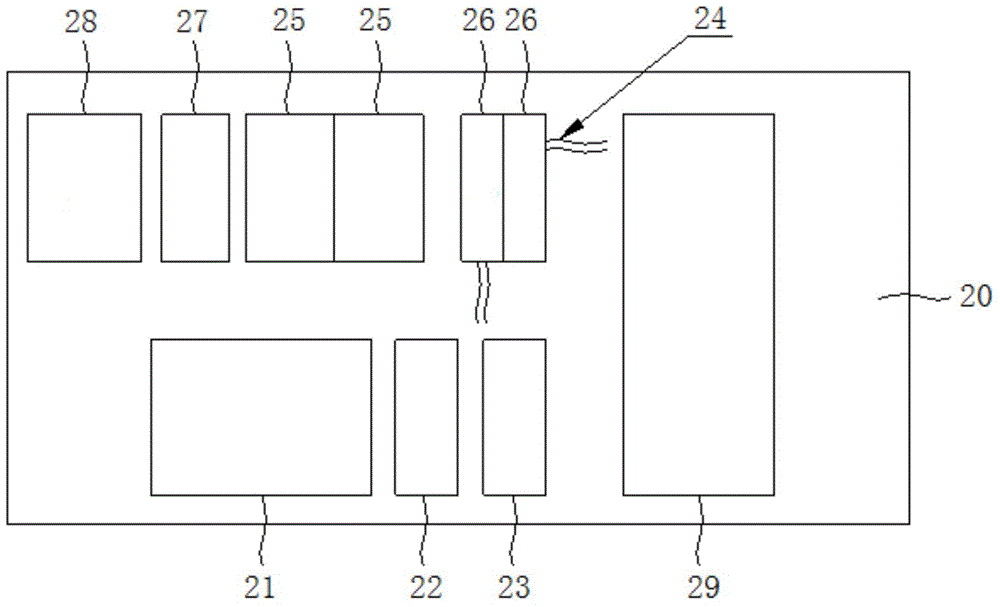

[0051] like figure 2As shown, this embodiment provides an offshore wind power foundation grouting work barge, includi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com