Metal compounded rubber vibration isolator

A rubber vibration isolator and metal composite technology, which is applied in the direction of spring/shock absorber, spring made of plastic material, spring, etc., can solve the problem of axial retraction, low strength of supporting shock absorber, and shortening the use of vibration isolator Life and other issues, to achieve the effect of prolonging the service life and improving the axial retraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

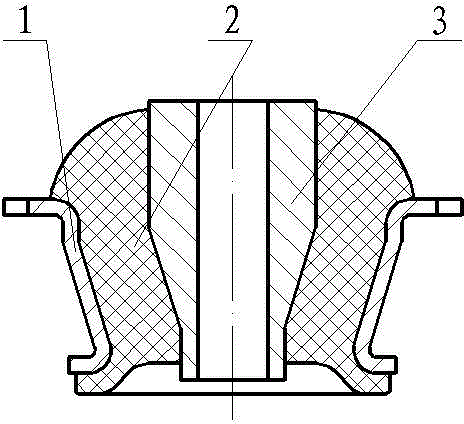

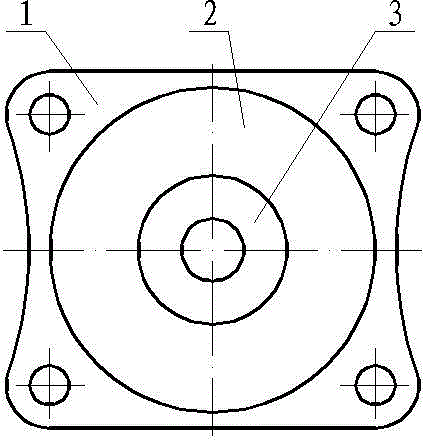

[0012] Such as figure 1 and figure 2 As shown, the present invention includes a housing 1, a rubber spring 2, and a positioning sleeve 3. The shell 1 is symmetrically provided with several flanges, and the middle is a frustum with an "L"-shaped cross section. The outer wall of the positioning sleeve 3 is provided with multiple steps, the positioning sleeve 3 is placed inside the housing 1 , and the rubber spring 2 is arranged between the positioning sleeve 3 and the inner wall of the housing 1 .

[0013] The rubber spring 2 extends to cover the bottom side plane of the "L" shaped part of the casing 1, forming an annular rubber lining.

[0014] In the present invention, through the rubber spring 2 between the shell 1 and the positioning sleeve 3, the vibration transmitted from the external component to the positioning sleeve 3 is converte...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap