Atomic dispenser for preparing atomic gas chamber and preparation method of atomic gas chamber

A technology of atomic gas chambers and dispensers, which is applied in the direction of instruments, measuring devices, electrical components, etc., can solve the problem of increased inhomogeneity of alkali metal atoms, difficulty in ensuring the uniformity of alkali metal distribution, and inability to achieve uniformity of alkali metal atoms Packing and other issues to achieve the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

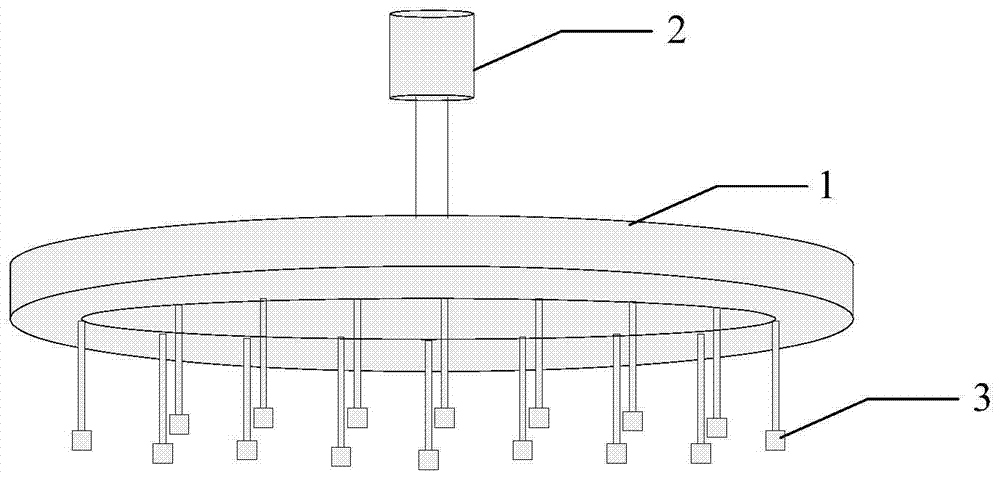

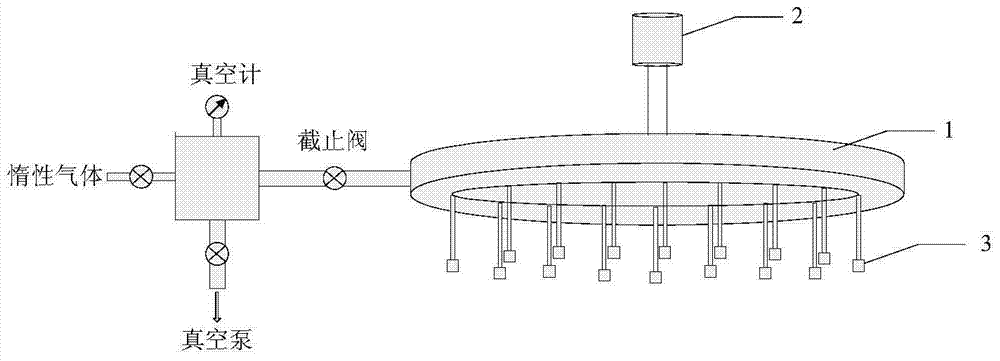

[0026] The atom packer for preparing atomic gas chamber of the present invention comprises a dispenser main body, gas chamber branch and alkali metal source, in figure 1 In the structural diagram of the atomic gas chamber dispenser shown, "1" is the main body of the dispenser, "2" is the alkali metal source, and "3" is the branch of the gas chamber. Wherein: the main body of the dispenser is a hollow disc, the alkali metal source is located at the center of the upper surface of the disc, and the gas chamber branch includes N atomic gas chambers, and the N atomic gas chambers are evenly distributed and connected to the dispenser On the lower surface of the main body, the distances between each atomic gas chamber and the alkali metal source are equal, and the alkali metal source and N atomic gas chambers are all connected to the inner hollow of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap