Anti-blocking coal slurry sampling apparatus

A sampling device and coal slurry technology, applied in the direction of sampling devices, etc., can solve the problems of affecting sampling accuracy, easy storage and easy blockage of sampling tubes, and achieve the effect of saving time and effort in sampling, and convenient installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

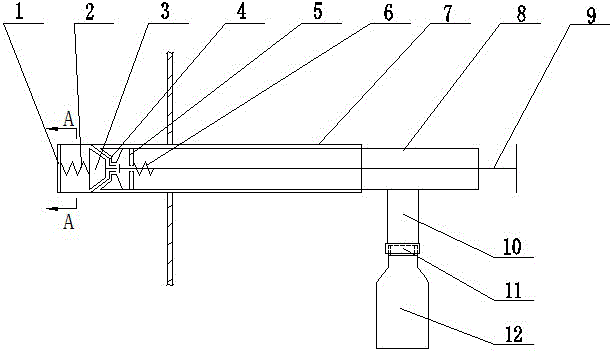

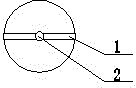

[0009] Referring to the accompanying drawings as follows, in figure 1 Among them, the first end of the one-way spool compression spring 2 is connected to the center of the one-way spool compression spring baffle 1, and the end of the one-way spool compression spring 2 is connected to the one-way spool 3, and the one-way spool 3 has a rod , the one-way valve seat 4 is connected to the sleeve pipe 7, and the sleeve pipe 7 is installed on the coal slurry storage tank. There is an opening on the one-way valve seat 4, so that the coal slurry enters the sampling pipe 8, and the sampling pipe 8 has a push rod 9. There is a baffle at the head end of the rod 9, which is convenient to transmit thrust to the pole on the one-way valve core 3. There is a push rod compression spring 6 on the push rod 9, and a push rod compression spring baffle 5 is welded on the inner wall of the sampling tube 8. The sampling tube 8 The shape of the head end coincides with the one-way valve seat 4, which ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com