A Calculation Method for Equivalent Advance Ratio Working Condition of Propeller in Duct

A propeller and advance ratio technology, applied in the field of efficient advance ratio calculation, can solve the problems that cannot be included in the duct-induced equivalent flow effect, initial condition error, and increase the number of iterative revisions, etc., to achieve large calculation economy and The effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0049] The present invention is a method for calculating the equivalent advance ratio working condition of the propeller in the duct, which is carried out according to the following steps:

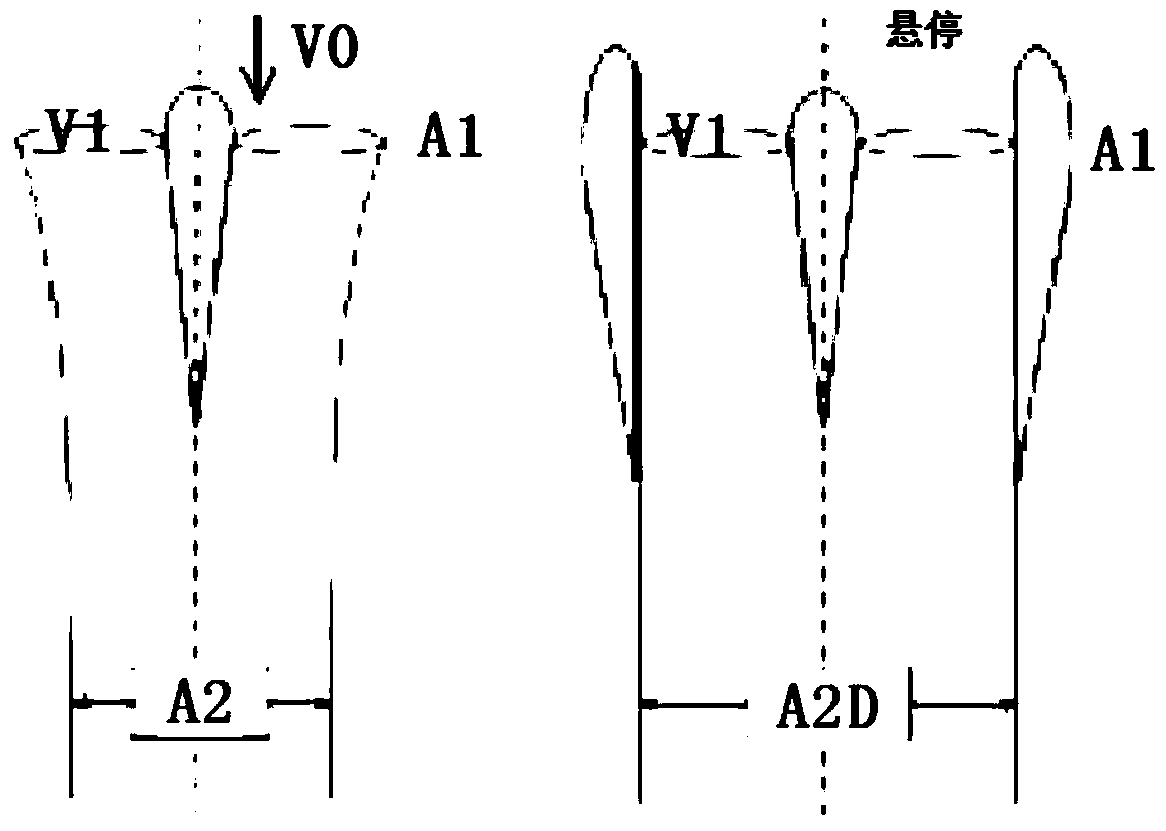

[0050] The advance ratio is also called the advance distance ratio, which is defined as where V 0 is the incoming flow velocity, in m / s. For the propeller in hovering condition, V 0 =0m / s, n is the rotation speed of the propeller, unit r / s, D propeller diameter.

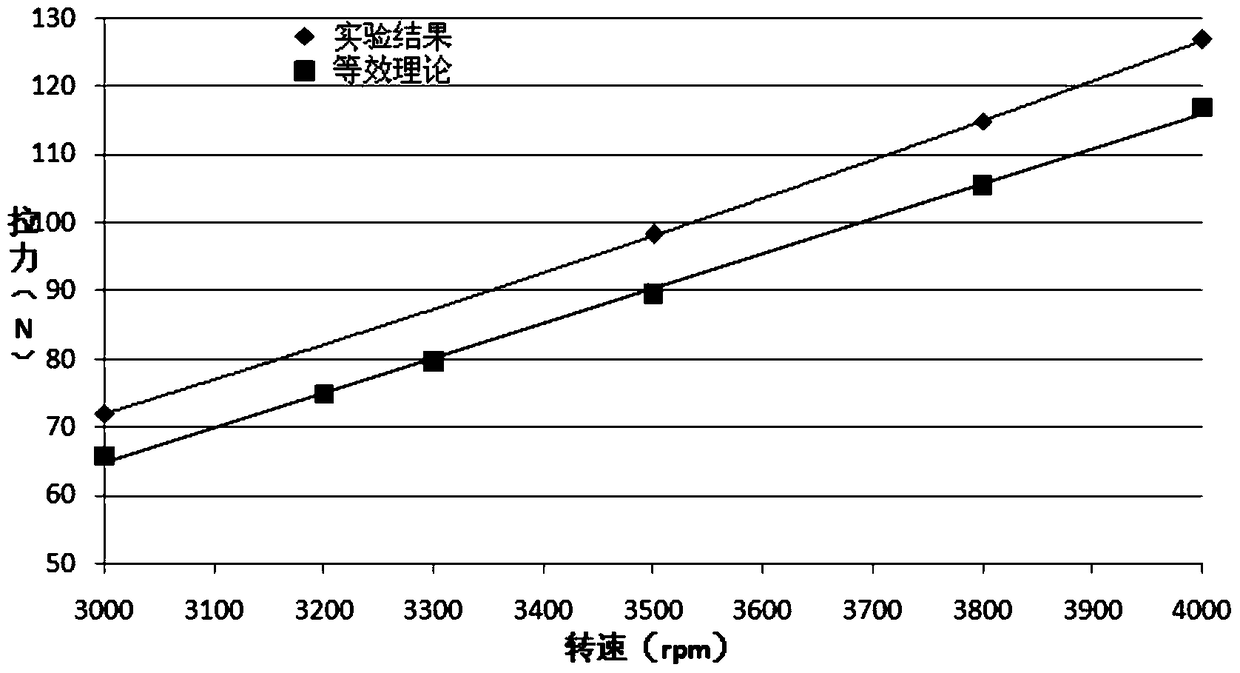

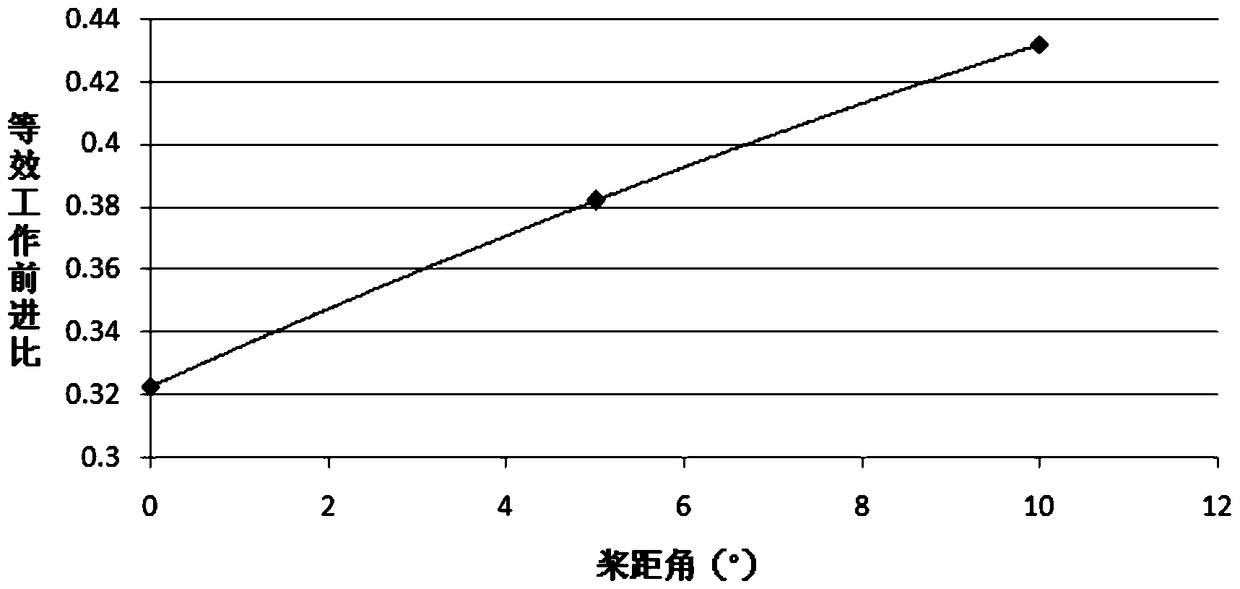

[0051] The equivalent advance ratio proposed by the present invention is to assume that the propeller under the action of the ducted propeller under the hovering condition is assumed to be under the equivalent working condition that the open propeller works at V with the same rotating speed. 0 Equivalent front flow conditions. where V 0 The induced velocity part is considered to be caused...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com