Manufacturing method of suit collar

A production method and collar technology, applied in the field of clothing production tooling, can solve the problems of high production cost, easy deformation, large difference in size and shape, etc., and achieve the effects of good product quality, high processing efficiency and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

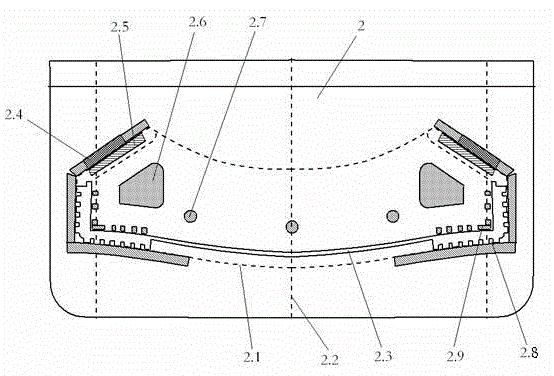

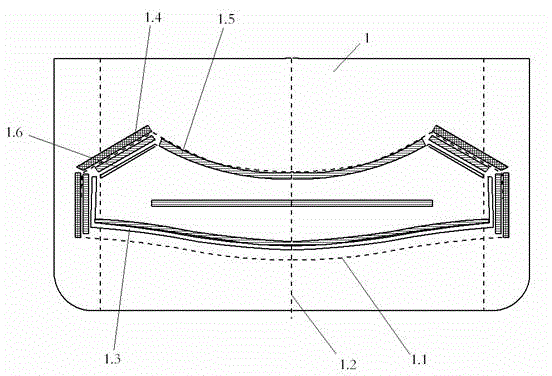

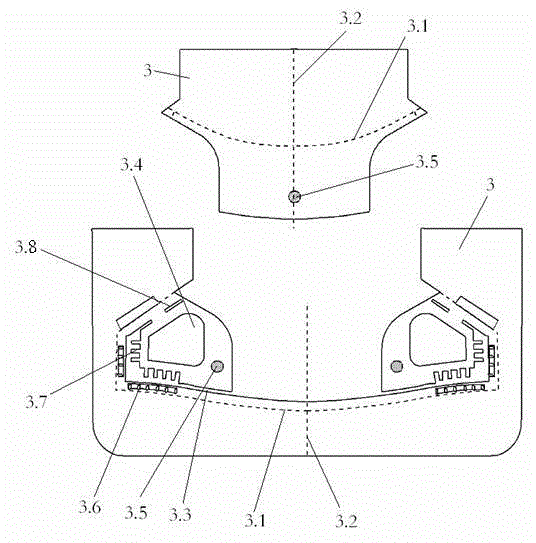

[0027] see Figure 1~Figure 3 , a kind of suit collar manufacturing method that the present invention relates to, this method adopts the suit collar making template to carry out positioning and sewing the inside of the collar and the collar surface, and the method comprises the following process steps:

[0028] 1. Place the trimmed collar on the upper surface of the base plate. The outer edge of the collar corresponds to the outer edge of the base plate. If there are longitudinal stripes in the collar, the vertical stripes correspond to the alignment line of the base plate;

[0029] 2. Place the middle plate cover on the upper surface of the bottom plate;

[0030] 3. Place the cut collar on the upper surface of the middle board. The outer edge of the collar corresponds to the outer edge of the middle board. If there are longitudinal stripes on the collar, the vertical stripes correspond to the alignment line of the middle board;

[0031] 4. Place the panel cover on the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com