Precise electric heating slicing device

A slicing device and precision electric technology, applied in the field of cutting machinery, can solve the problems of uneven and convex edges, not enough fit, and insufficient slicing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

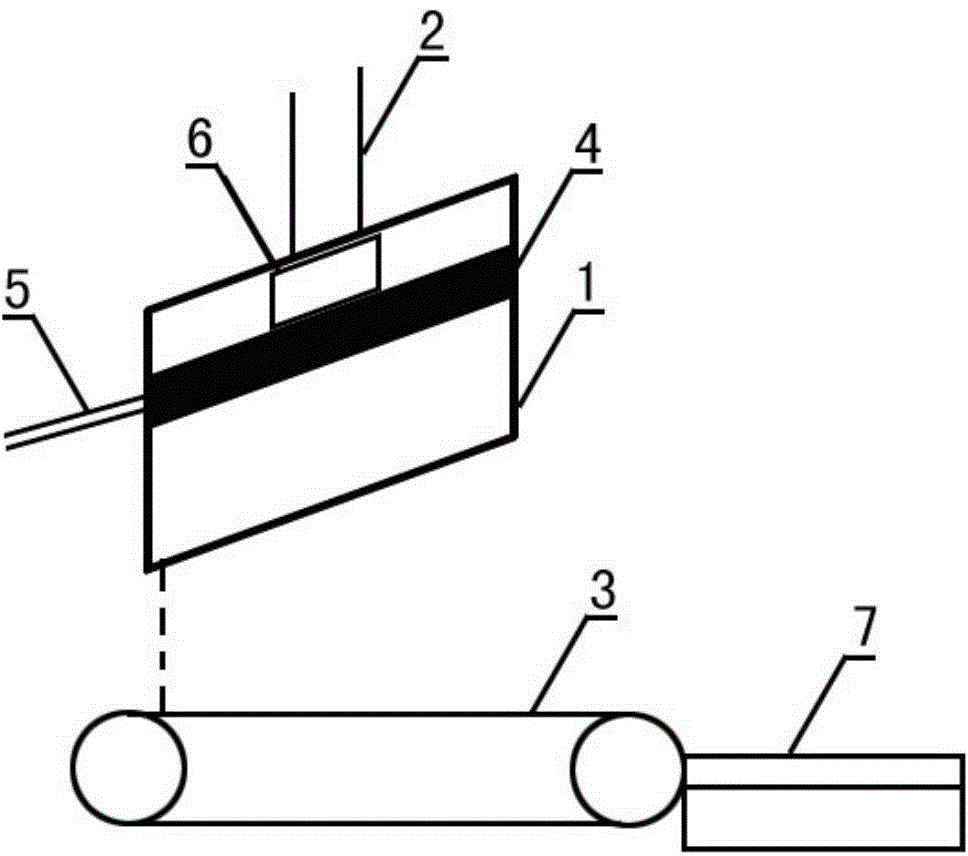

[0013] Embodiment: as shown in the accompanying drawing. A precision electric heating slicing device, comprising a blade (1), which is detachable and replaceable and has good thermal conductivity, a telescopic rod (2) is arranged above the blade to control the cutting of the blade, and an electric conveyor belt (3) is arranged below the blade, Drive the cutting object to move, and use the speed to control the thickness of the slice.

[0014] A precision electric heating slicing device, a heater (4) is arranged above the blade to heat the blade to a high degree to facilitate cutting.

[0015] A precision electric heating slicing device, a heater (4) is provided with an electric wire (5) to provide electric power for the heater.

[0016] A precision electric heating slicing device, the cutting blade (1) is designed for high temperature resistant material.

[0017] A precision electric heating slicing device, a control center (6) is arranged above the blade to control the cutti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com