Uniform slice chopping and separating machine

A slicing machine and slicing technology, which is applied in metal processing and other directions, can solve the problems of large volume, slow slicing, easy to wet, etc., and achieve the effect of simple slicing operation, simple structure and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

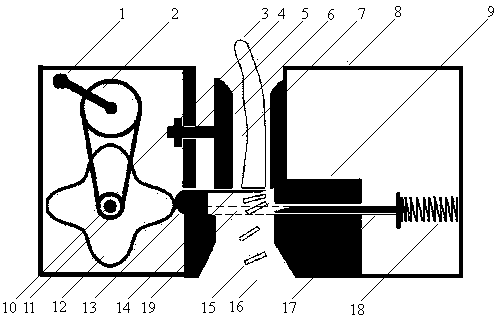

[0015] Below in conjunction with the accompanying drawings, a further implementation description will be given to a cutting machine for equalizing and slicing.

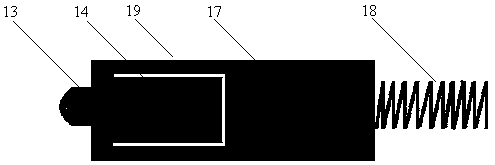

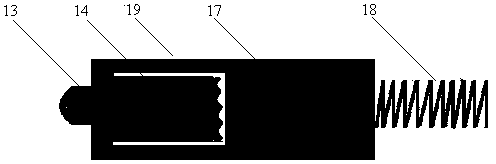

[0016] figure 1 It is a side view of the middle section structure principle of an equalizing and slicing machine. In the picture, we see a cuboid-shaped machine mainly surrounded by a shell 8. There is a hand rocker protruding from the side of the upper left corner of the cuboid. There is an entrance 7 in the middle of the upper part of the cuboid and an exit 16 in the middle of the lower part. There is an entrance on the side wall of the entrance 7. Wall 6 can be regulated by the adjusting screw 5 on the side to move left and right, to adjust the expansion or contraction entrance, so as to fit melons and fruits of different sizes into it. Take cucumber 3 as an example. When cucumber 3 enters the entrance 7 and falls due to gravity, it bumps into a lower baffle 17. When a person shakes it, the lower baffle 17 is not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com