Constant-speed mixing equipment for producing nylon 6 injection molding slices and production method of nylon 6 injection molding slices

A technology of mixing equipment and production method, which is applied in the field of mixing equipment modified by nylon 6 slices, can solve the problems of easy concentration and falling directly below the discharge port, troublesome collection of nylon 6 injection molding slices, and slow drying speed, etc., to achieve Ensure highly dispersed mixing, ensure particle integrity, and prevent contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

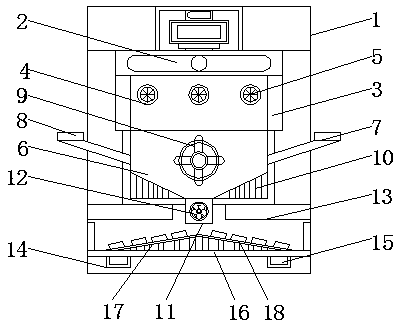

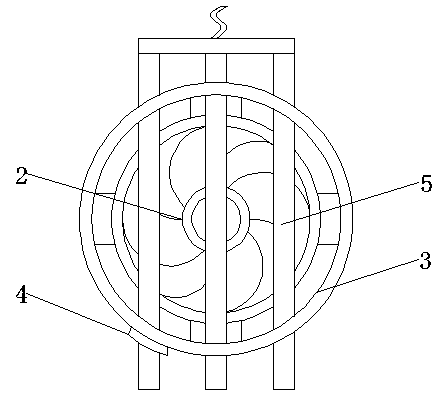

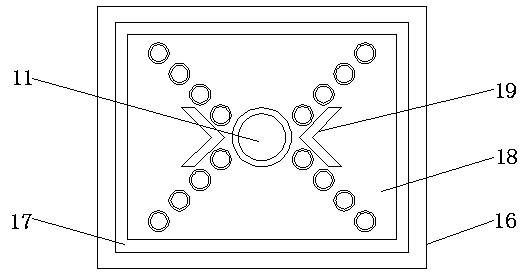

[0030] see Figure 1-3 , the present invention provides a technical solution: a uniform mixing equipment for the production of nylon 6 injection molding slices, including a casing 1, a stirring box 6 and a movable box 16, a fan 2 is installed inside the casing 1, and the lower edge of the fan 2 A baffle 3 is welded, the surface of the baffle 3 is provided with a circular groove 4, and the interior of the circular groove 4 runs through a baking lamp 5, the baffle 3 is connected with the baking lamp 5 through the circular groove 4, and the baking The lamps 5 are evenly distributed along the horizontal direction of the fan 2, and the baking lamps 5 are parallel to each other. The position is fixed, so that the baking lamp 5 is suspended and fixed under the fan 2, and the fan 2 can directly diffuse the heat emitted by the baking lamp 5 downwards in the working state, so that the heat emitted by the baking lamp 5 The heat falls on the nylon 6 slices quickly and accurately, which s...

Embodiment 2

[0034] A method for producing nylon 6 injection-molded slices, using the above-mentioned constant speed mixing equipment, the specific steps are as follows: both ends of the baking lamp 5 are inserted into the inside of the circular groove 4, and the two ends of the baking lamp 5 are heated through the circular groove 4. Fix the position, so that the baking lamp 5 is suspended and fixed under the fan 2, and the nylon 6 slices are injected into the inside of the mixing box 6 through the first feeding pipe 7, and then it is baked by the baking lamp 5 and the fan 2 Dry operation, after the drying of the nylon 6 slices, the white oil is injected into the inside of the stirring box 6 through the second feed pipe 8, and the white oil and the nylon 6 slices are mixed at a low speed for 10 minutes through the stirring mechanism 9, because the nylon 6 slices It is a solid structure, so when the nylon 6 slices pass through the first feeding pipe 7, it is not easy to remain on the inner w...

Embodiment 3

[0040] A method for producing nylon 6 injection-molded slices, using the above-mentioned constant speed mixing equipment, the specific steps are as follows: both ends of the baking lamp 5 are inserted into the inside of the circular groove 4, and the two ends of the baking lamp 5 are heated through the circular groove 4. Fix the position, so that the baking lamp 5 is suspended and fixed under the fan 2, and the nylon 6 slices are injected into the inside of the mixing box 6 through the first feeding pipe 7, and then it is baked by the baking lamp 5 and the fan 2 Dry operation, after the drying of the nylon 6 slices, the white oil is injected into the inside of the stirring box 6 through the second feed pipe 8, and the white oil and the nylon 6 slices are mixed at a low speed for 10 minutes through the stirring mechanism 9, because the nylon 6 slices It is a solid structure, so when the nylon 6 slices pass through the first feeding pipe 7, it is not easy to remain on the inner w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com