Circuit board clamp capable of achieving rapid clamping

A circuit board and clamping technology, which is applied in the direction of manufacturing tools and workpiece clamping devices, can solve the problems of high brittleness of circuit boards, high scrap rate, and damage to the board body, so as to save manpower, reduce contact area, and prevent circuit boards from being damaged. The effect of plate damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

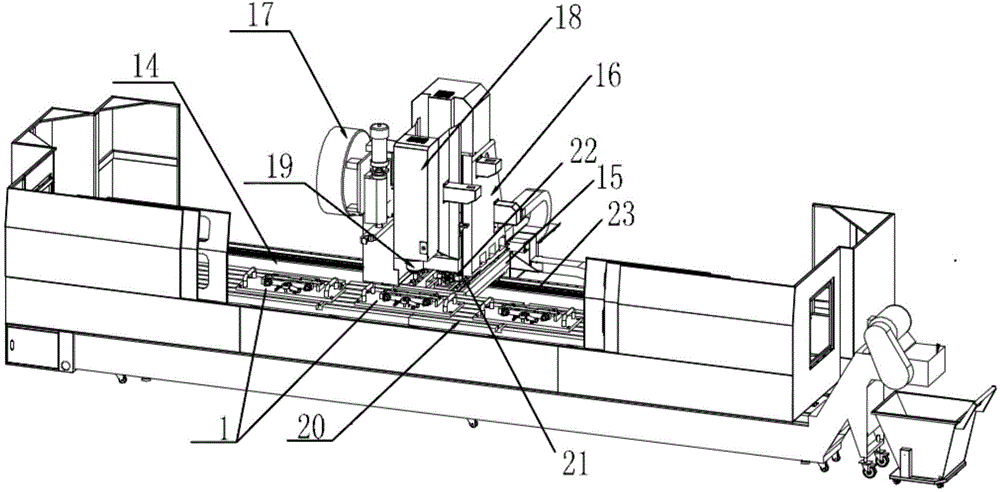

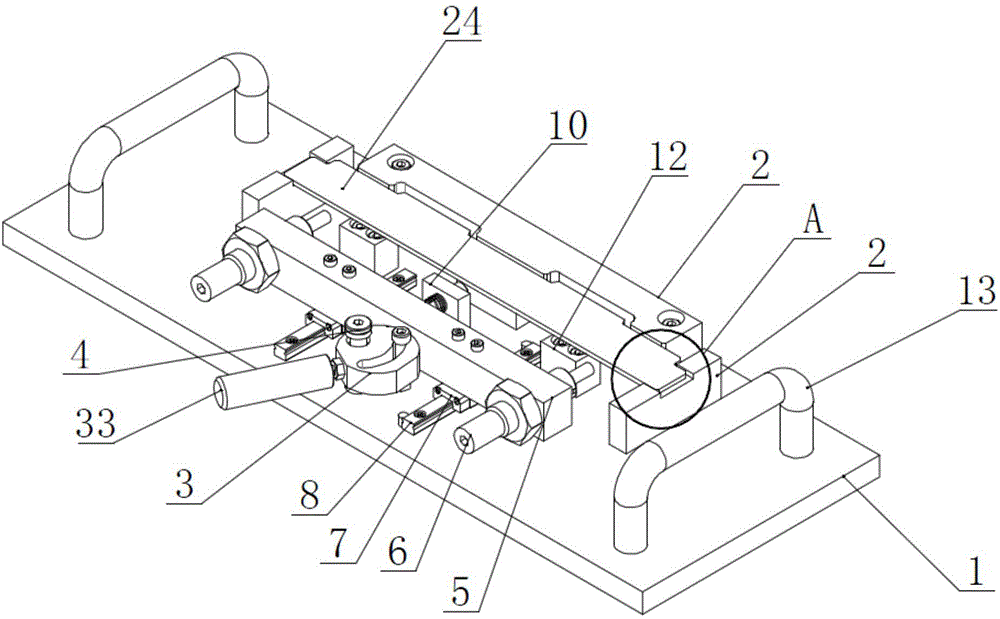

[0032] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0033] Such as figure 1 and figure 2 As shown, a circuit board fixture for fast clamping includes a base 1; the base 1 is provided with several positioning blocks 2, eccentric wheels 3, eccentric shafts 4, movable guide blocks 5, positioning rods 6, sliders 7 and wires rail 8, the positioning rod 6 is vertically fixed on the movable guide block 5, the plane formed by the centerlines of the two is parallel to the upper end surface of the base 1, and the line rail 8 is fixed on the base 1;

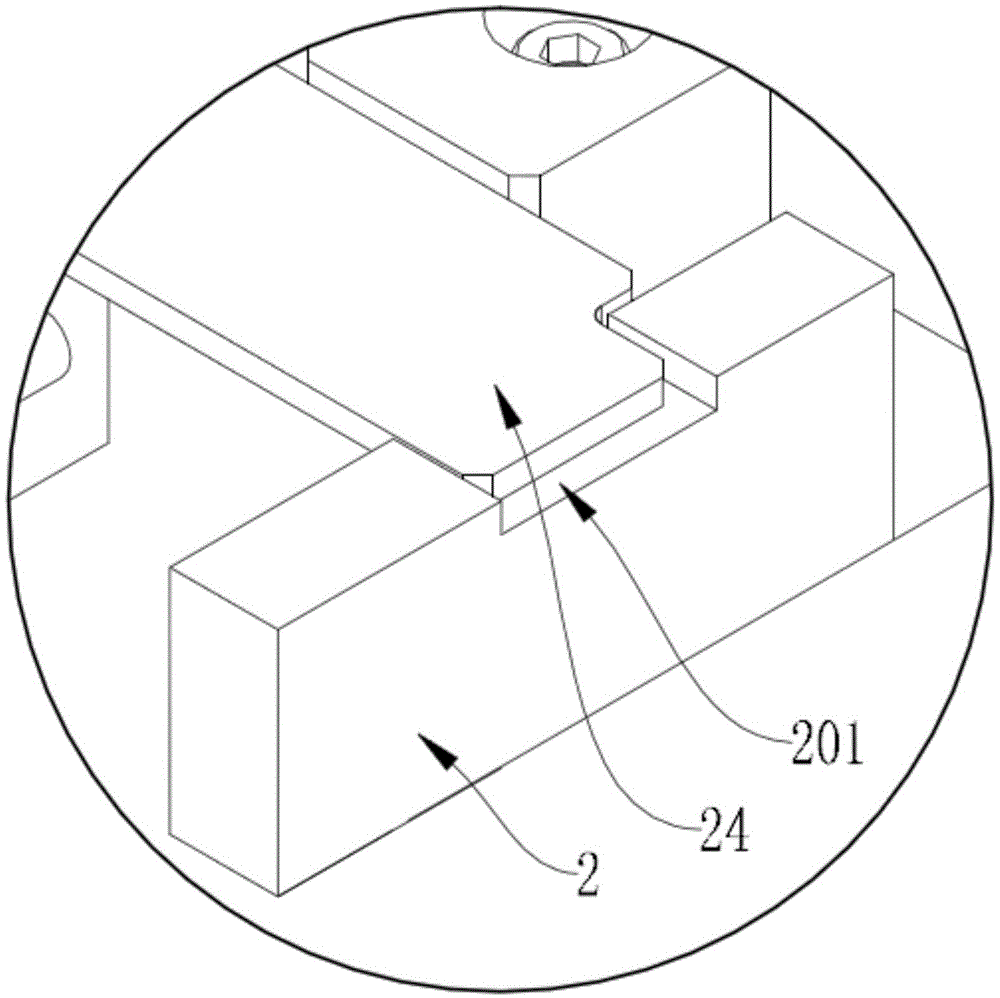

[0034] The positioning block 2 is provided with a workpiece limiting part 201, and several positioning blocks 2 are fixed on the base 1 in an arrangement suitable for the shape of the workpiece 24. When clamping, the workpiece limiting part 201 is in contact with the edge side wall of the workpiece 24, The work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com