Passive triggered tire pressure monitoring system and method

A tire pressure detection and trigger technology, applied in the field of passive trigger tire pressure detection systems, can solve the problems of increasing power consumption, increasing data transmission, the accuracy of receiving tire pressure data, and the consideration of power consumption efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical means adopted by the present invention to achieve the intended invention purpose are further described below in conjunction with the drawings and preferred embodiments of the present invention.

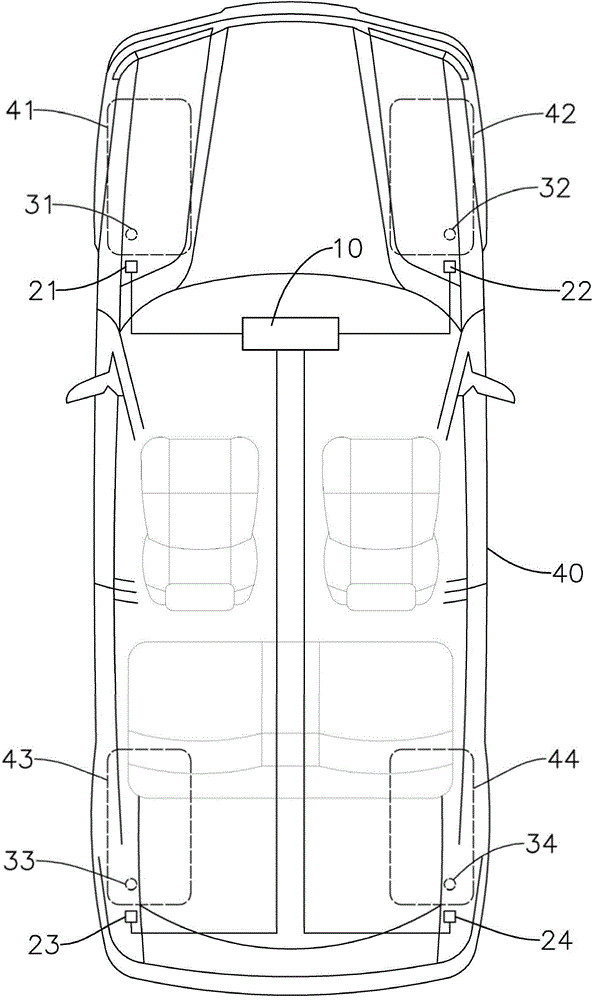

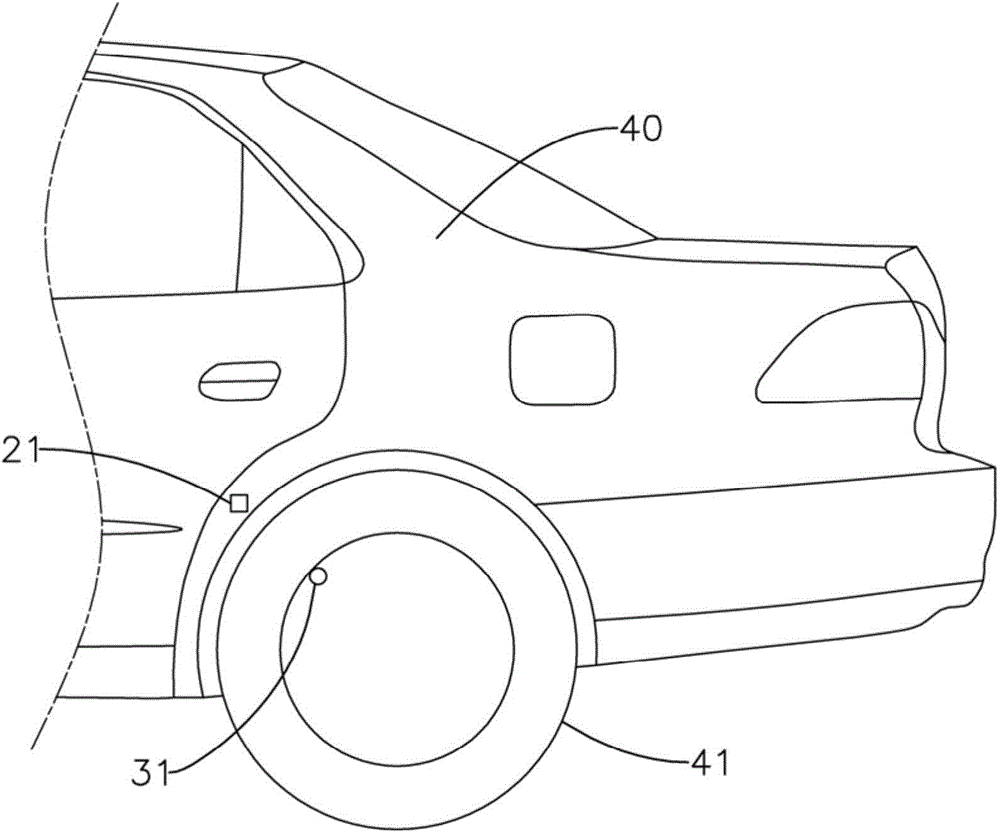

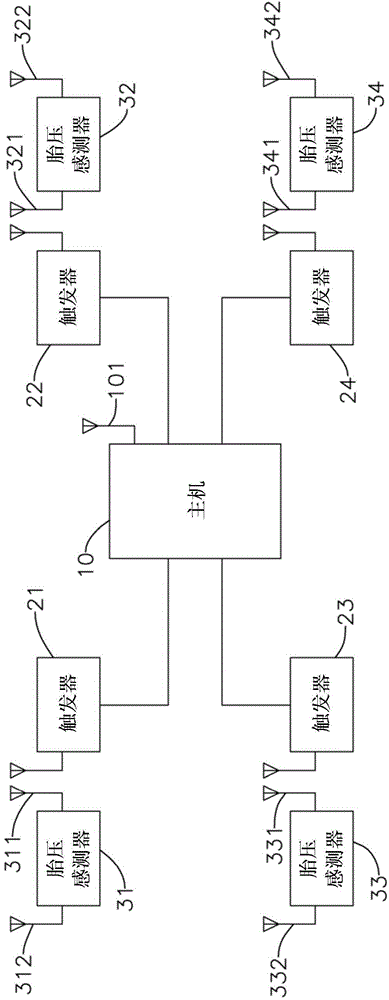

[0026] Regarding a preferred embodiment of the tire pressure detection system of the present invention, first please refer to figure 1 As shown, it includes a host 10, more than one trigger and more than one tire pressure sensor; wherein, the trigger and the tire pressure sensor are set in a one-to-one manner. In the following embodiments, a general four-wheeled car will be used as the application object. Therefore, in this embodiment, the tire pressure detection system of the present invention will have four triggers and four tire pressure sensors. However, those who have ordinary knowledge in the technical field can understand that: the tire pressure sensors are arranged on the tires one-to-one, and the number is related to the number of tires used in the vehic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com