Variable-thickness automobile roof middle cross beam and manufacturing method thereof

A technology of automobile roof and manufacturing method, which is applied in the direction of vehicle components, upper structure, upper structure sub-assembly, etc., can solve the problems that do not involve the design of the section shape of the part according to the manufacturing method of the part sheet, and achieve the realization of light weight of the car body, Good surface quality and good lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

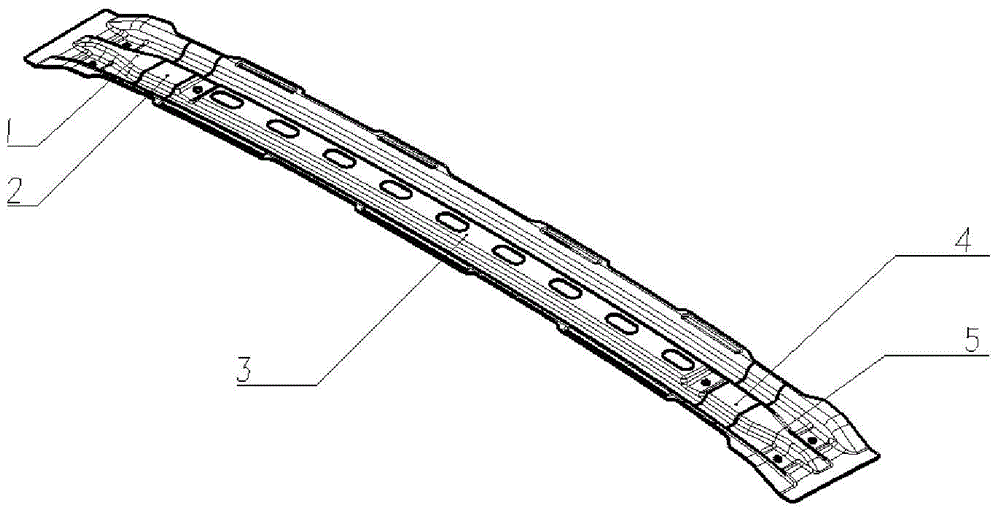

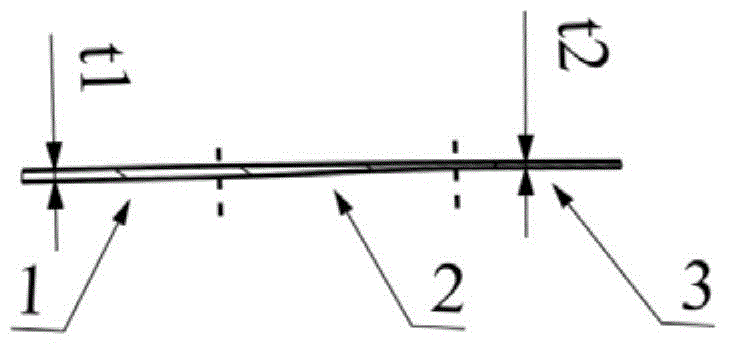

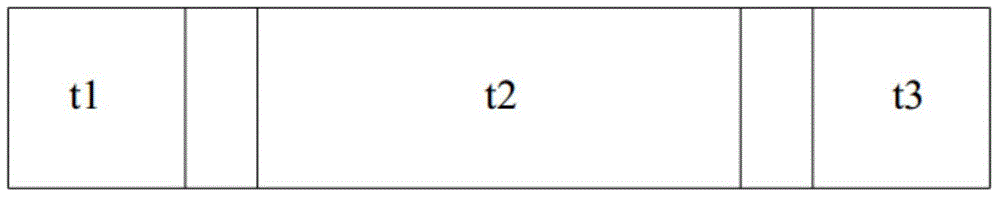

[0032] see figure 1 , a middle beam of a variable-thickness automobile roof according to the present invention, wherein the body of the roof middle beam is a thin-walled structure, which successively includes the left section 1 of the body, the left transition section 2, the middle section 3 of the body, the right transition section 4 and the body Right section 5; the left section 1 of the body and the right section 5 of the body are connected with the B-pillar of the side wall of the automobile, and this section is a structure of equal thickness; the left transition section 2 and the right transition section 4 are continuously variable thickness structures, and their thickness The thickness of the middle section 3 of the body gradually decreases from the thick area at both ends to the thin area of the middle section 3 of the body; the thickness of the middle section 3 of the body is the thinnest in the body of the beam in the top cover.

[0033] Preferably, the thickness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com