Packing container for liquid crystal display panel

A liquid crystal display panel and box body technology, which is applied in the direction of transportation and packaging, packaging of vulnerable items, and types of packaged items, can solve the problems of unsatisfactory packaging performance of liquid crystal display panels and difficult protection of liquid crystal display panels, so as to avoid damage, The effect of reducing vibration and simplifying the packing box

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

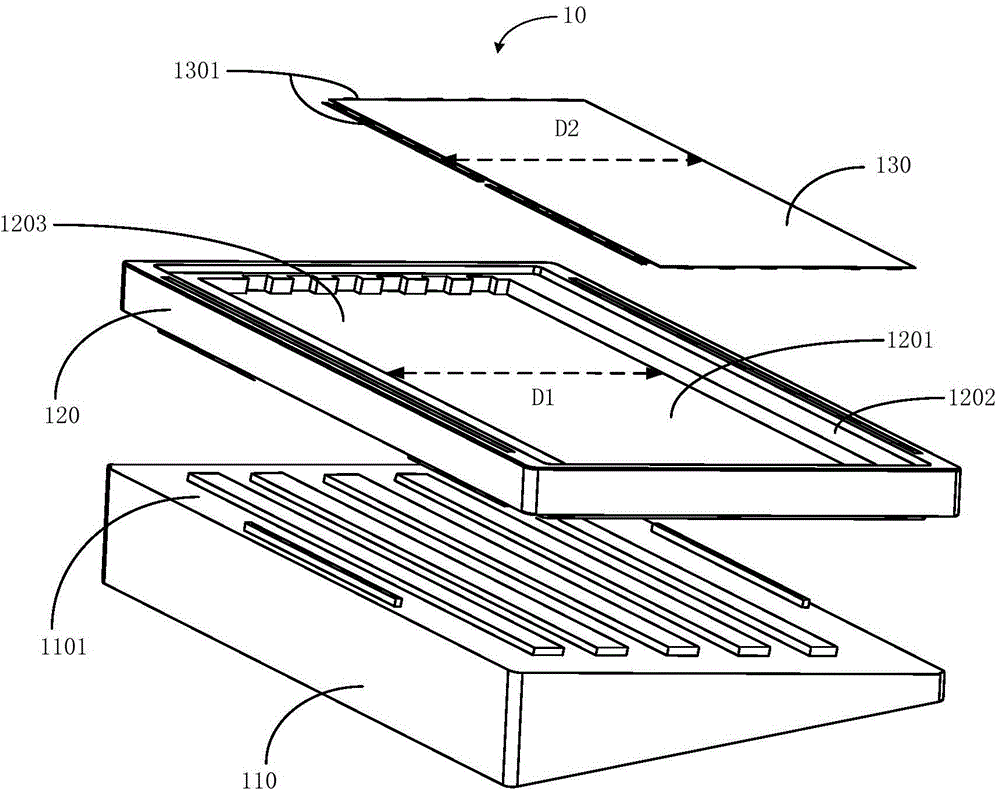

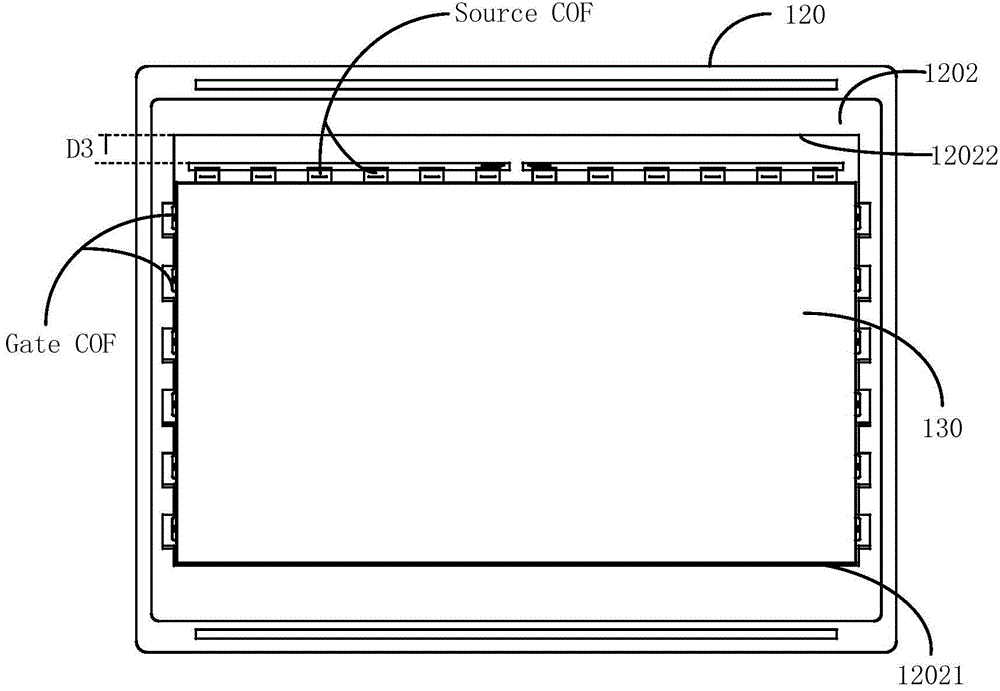

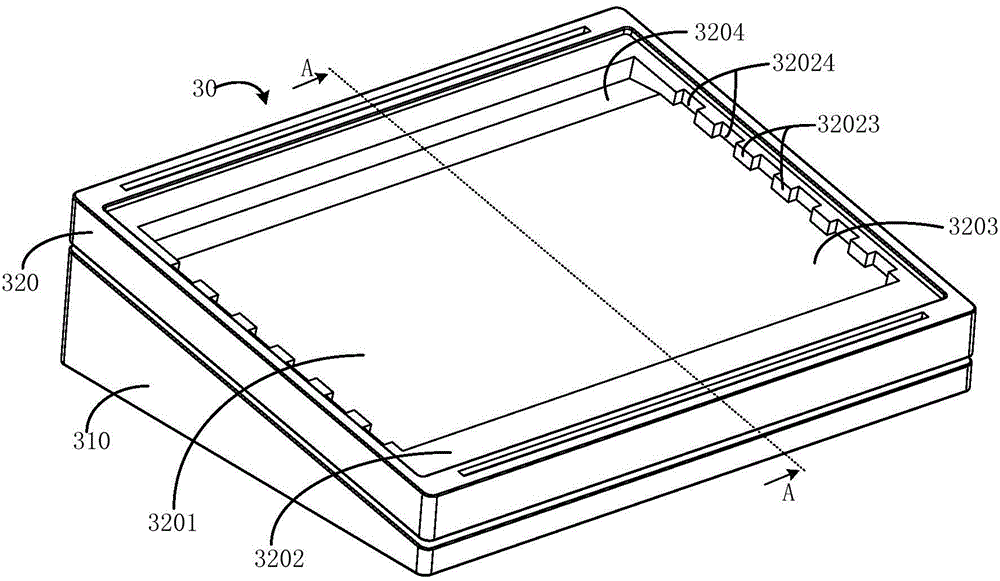

[0062] see figure 1 and figure 2 , figure 1 It is a schematic diagram of the exploded structure of the first embodiment of the packaging box for liquid crystal display panels provided by the present invention; figure 2 yes figure 1 Schematic diagram of the top view structure of the center-slanted cabinet with the liquid crystal display panel placed in it.

[0063] The packaging box 10 includes:

[0064] The chassis 110 and the inclined box body 120 are used to place the drive circuit film 1301 and the PCB circuit board 1302 ( figure 1 Not shown in the liquid crystal display panel 130;

[0065] The top surface 1101 of the chassis 110 is a first inclined surface, and the inclined box 120 is inclined on the first inclined surface 1101;

[0066] The inclined box 120 includes a second inclined surface 1201 and a limiting frame 1202;

[0067] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com