A kind of method and technical process thereof for treating neopentyl glycol mother liquor in ibuprofen synthesis process

A technology for the mother liquor of neopentyl glycol and pentylene glycol, applied in the separation/purification of hydroxyl compounds, organic chemistry, etc., can solve the problems of difficult wastewater treatment, large proportion, and difficult secondary treatment of wastewater, and achieve water vapor saving The effect of reducing consumption, reducing production and running costs, and saving processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

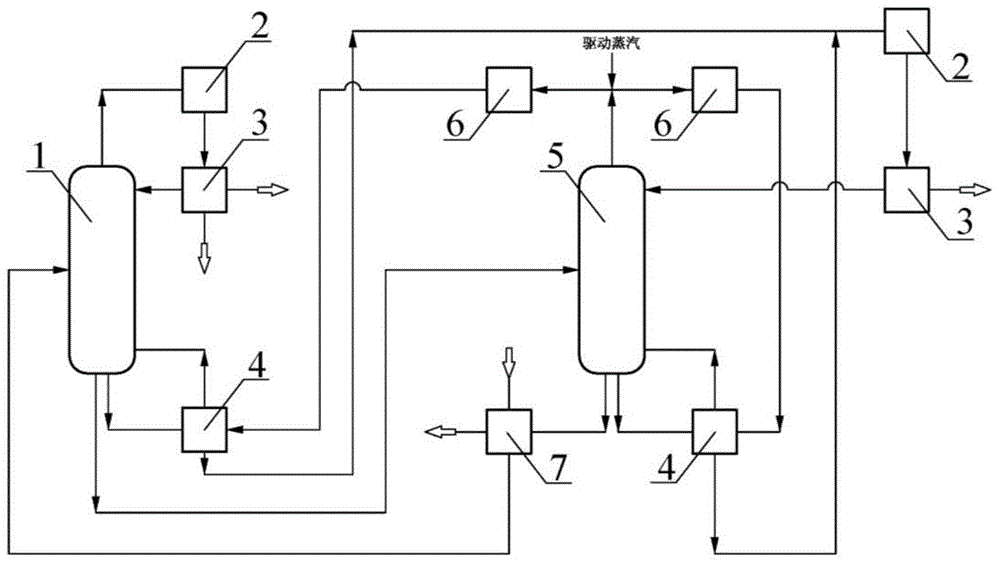

Image

Examples

Embodiment 1

[0026] Implementation Example 1: The neopentyl glycol mother liquor flow rate is 3500 kg / h, after being preheated by the preheater, the temperature rises from 25.5°C to 76.4°C, and the temperature at the bottom of the rectification tower decreases from 121.6°C to 97.3°C. The driving steam pressure is 0.12Mpa, the flow rate is 2100kg / hour, the pressure of the fresh steam after compression is 0.51Mpa, and the temperature is 151.9°C. The quality of monochloromethane produced at the top of the stripper is 120.2 kilograms, the quality of dichloromethane is 119.1 kilograms, and the quality of petroleum ether is 90.0 kilograms. When the temperature at the top of the rectification tower reaches 103.7°C, stop driving the steam, compress the gas at the top of the rectification tower so that the pressure is 0.55Mpa, and the temperature is 155.5°C, then heat the stripping tower and the bottom reboiler of the rectification tower. The mass content of neopentyl glycol in the water extracted ...

Embodiment 2

[0027] Implementation Example 2: The neopentyl glycol mother liquid flow rate is 3700 kg / h, the temperature rises from 27.4°C to 72.2°C after being preheated by the preheater, and the temperature at the bottom of the rectification tower decreases from 108.1°C to 95.2°C. The driving steam pressure is 0.14Mpa, the flow rate is 2220 kg / h, the pressure of the fresh steam after compression is 0.52Mpa, and the temperature is 153.4°C. The quality of monochloromethane produced at the top of the stripper is 110.5 kilograms, the quality of dichloromethane is 124.5 kilograms, and the quality of petroleum ether is 94.1 kilograms. When the temperature at the top of the rectification tower reaches 104.8°C, stop driving the steam, compress the gas at the top of the rectification tower so that the pressure is 0.54Mpa, and the temperature is 154.8°C, then heat the stripping tower and the bottom reboiler of the rectification tower. The mass content of neopentyl glycol in the water extracted fro...

Embodiment 3

[0028] Implementation Example 3: The neopentyl glycol mother liquor flow rate is 5000 kg / h, after being preheated by the preheater, the temperature rises from 35.2°C to 75.1°C, and the temperature at the bottom of the rectification tower decreases from 126.2°C to 99.6°C. The driving steam pressure is 0.15Mpa, the flow rate is 3100kg / hour, the pressure of the fresh steam after compression is 0.58Mpa, and the temperature is 157.6°C. The quality of monochloromethane produced at the top of the stripper is 110.5 kilograms, the quality of dichloromethane is 124.5 kilograms, and the quality of petroleum ether is 94.1 kilograms. When the temperature at the top of the rectification tower reaches 104.1°C, stop driving the steam, compress the gas at the top of the rectification tower so that the pressure is 0.60Mpa, and the temperature is 158.9°C, then heat the stripping tower and the bottom reboiler of the rectification tower. The mass content of neopentyl glycol in the water extracted ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com