Large-span reinforced concrete orthogonal-diagonal open-web floor and manufacturing method thereof

A technology of reinforced concrete and a manufacturing method, which is applied to floors, building components, buildings, etc., can solve the problems of uneven force on the floor, waste of materials and cost, and save the thickness of the floor, reduce the project cost, and achieve uniform force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

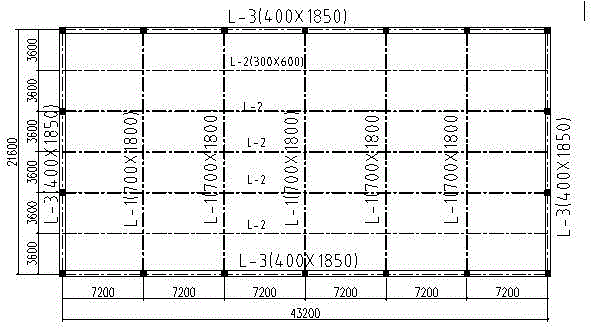

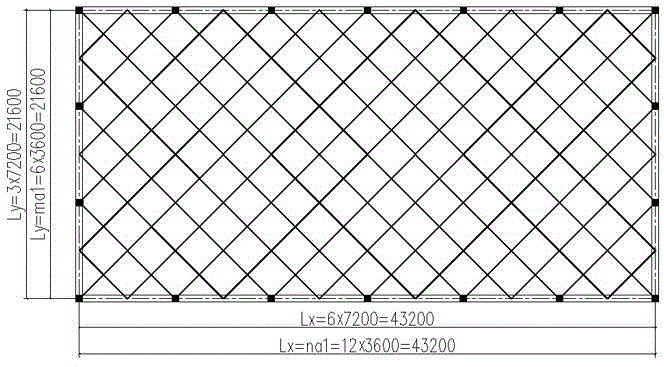

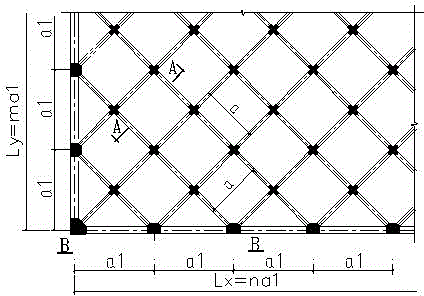

[0034] In the embodiment, the large-span reinforced concrete is placed vertically and obliquely on the hollow floor, and the perimeter of the building floor is an isosceles triangle grid, and the middle is along the perimeter of 45 0 The corner is a square fasting grid, the size a of the right-angled side of the surrounding isosceles triangle and the length of the hypotenuse of the isosceles triangle a 1 for a=a 1 × sin45° relationship, that is, the surrounding grid a 1 After being determined, the size of the internal square grid a along the 45° direction is also determined.

[0035] by figure 1 The shown floor is taken as an example to describe in detail. There is a reinforced concrete girder every 7.2m in the length direction, and a secondary beam every 3.6m. The surrounding concrete connecting beams are connected with the girders as a whole, forming 43.2m×21.6m=933.12 m 2 The large-area floor of this traditional structure causes high engineering costs and hinders the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com