Spray Axial Fans with Sidewall Spray Tubes

A technology of axial fans and water spray pipes, which is applied in the field of fluid mechanical devices, can solve the problems of narrow operating range, reduced fan flow and efficiency, and large pipe resistance of spray fans, so as to reduce the energy consumption of moving blades and improve Total pressure, efficiency, and low vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The structure and working principle of the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

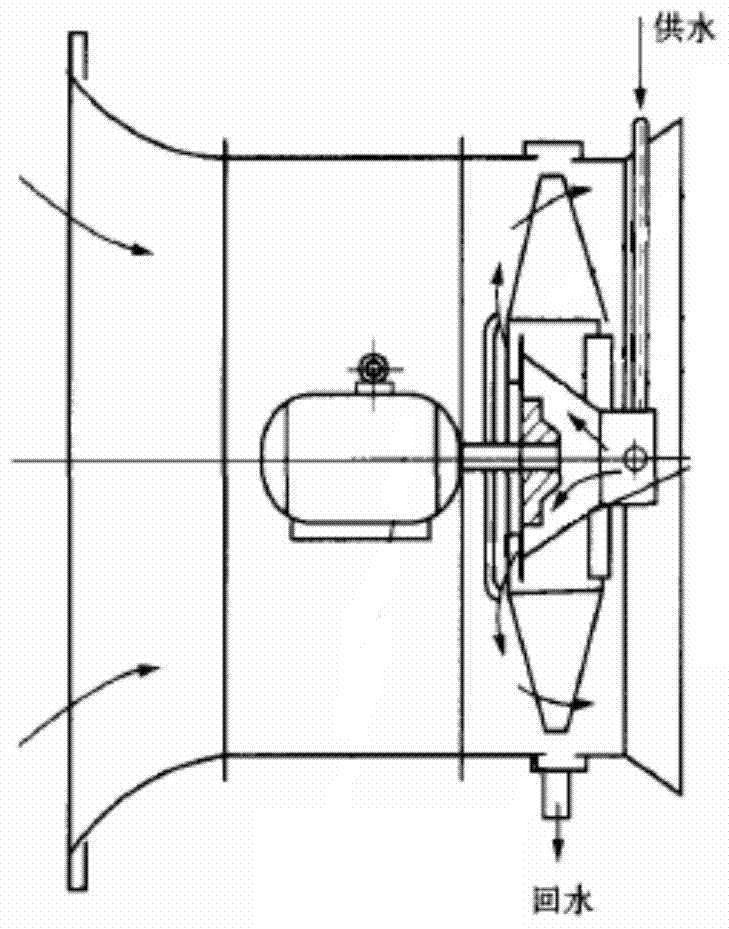

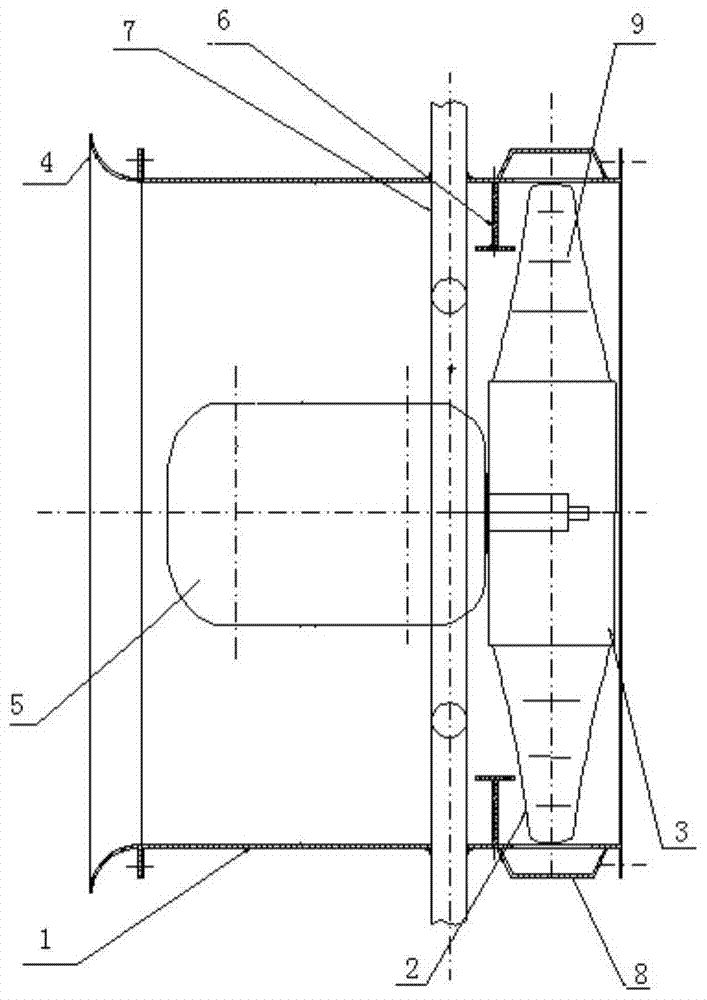

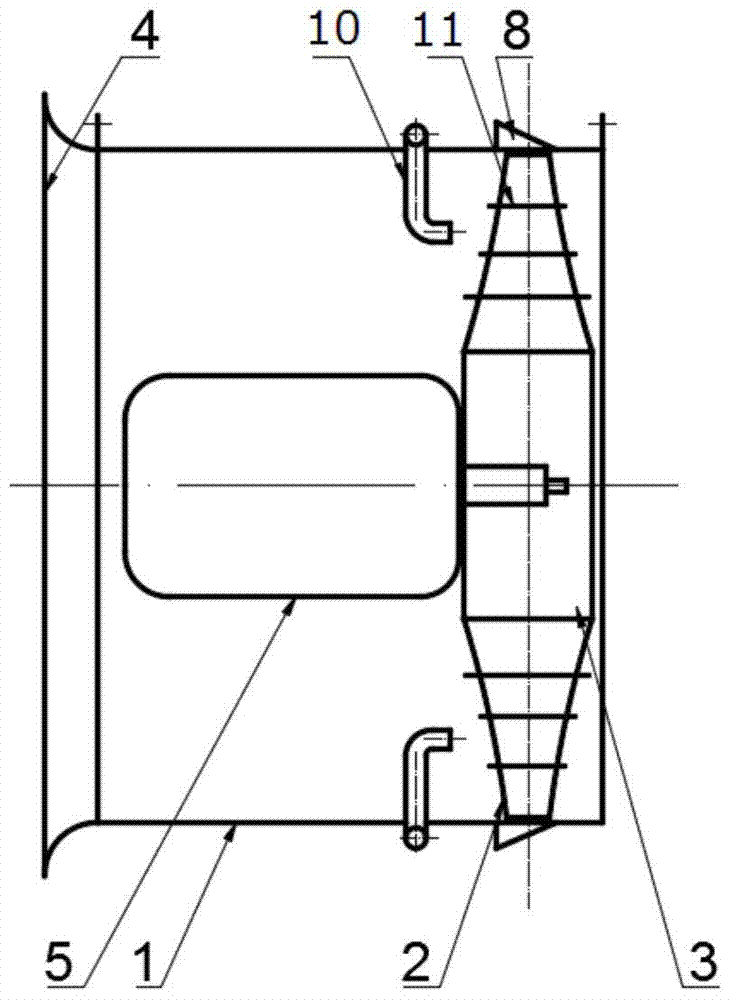

[0024] refer to image 3 , a spray axial fan with a side wall water spray pipe, including a collector 4, a fan duct 1, a motor 5, a hub 3, a moving blade 2 and a water-repellent grid 8, before the impeller inlet, the motor 5 and the hub 3 Between the inner and outer walls of the fan duct, a side wall water spray pipe 10 is arranged, and a radial water blocking device 11 is arranged on the moving blade 2 .

[0025] refer to Figure 4 , the side wall water spray pipe 10 is composed of a water delivery ring pipe 13 placed on the outer wall of the fan duct and a plurality of water spray pipe heads 12 extending into the inner wall of the fan duct, and each water spray pipe head is connected with the water delivery ring pipe. 13 is connected, and a plurality of water spray pipe heads are evenly distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com