Spraying axial-current fan with ring-shaped water-jet pipe

A technology of annular water spraying and axial flow fans, which is applied in home appliances, mechanical equipment, machines/engines, etc., can solve the problems of strong force of blades hitting water droplets, narrow range of working conditions, and burning motors, etc., to reduce the energy of moving blades consumption, increased safety, and reduced wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

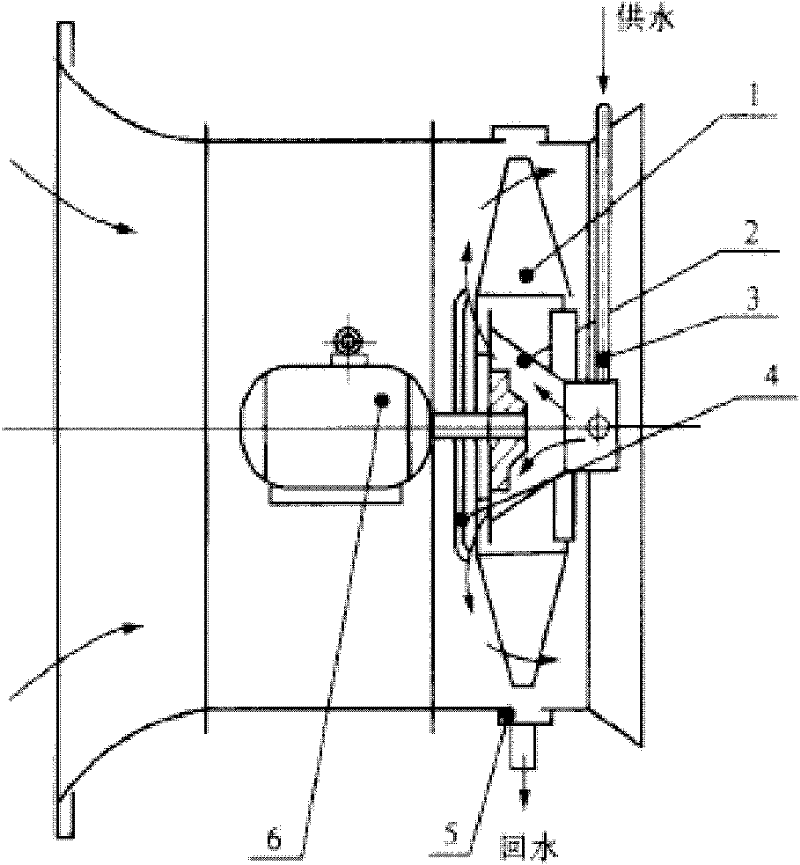

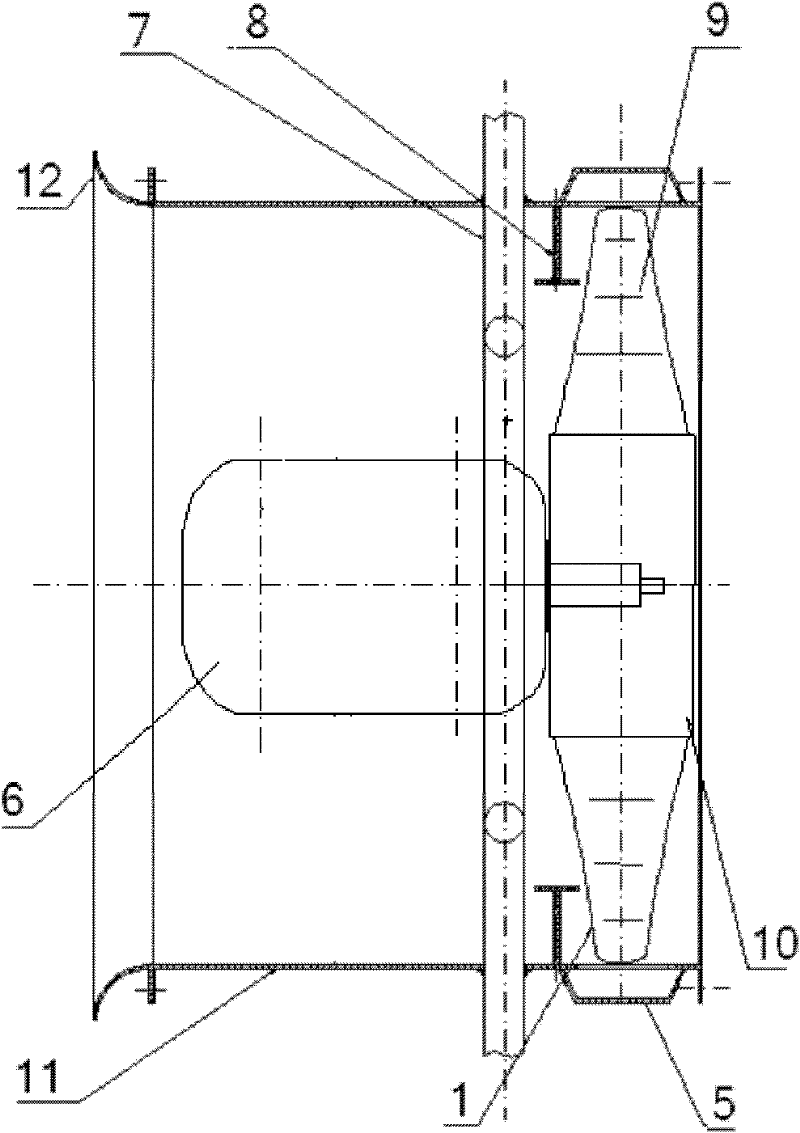

[0016] see figure 2 , a spraying axial flow fan with an annular water spray pipe, comprising a collector 12, a fan cylinder 11, a motor 6, a wheel hub 10, moving blade blades 1 and a drain grid 5, between the motor 6 and the wheel hub 10, set There are annular water spray pipes 7 and radial water retaining rings 8, and additional guide vanes 9 are arranged on the rotor blades 1.

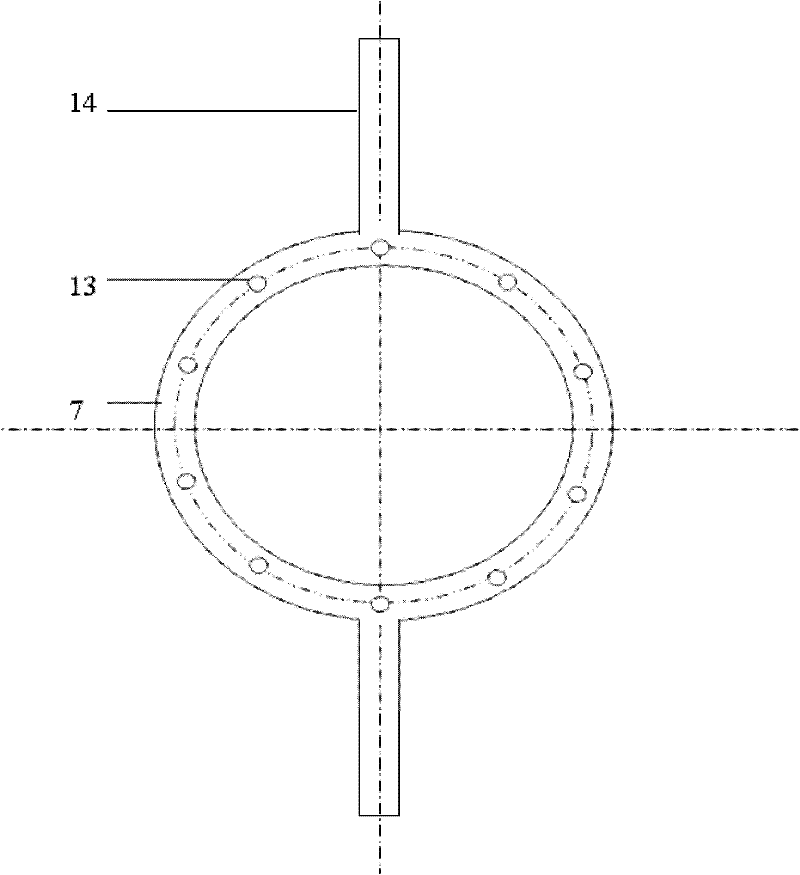

[0017] see image 3 , the above-mentioned annular water spray pipe 7 is passed into the water flow through the water delivery pipe 14, and the side of the water spray pipe facing the rotor blade 1 is provided with 6 to 10 circumferentially evenly distributed circular or other shaped (such as ellipse) small water spray pipes. Hole 13, a small section of pipe can also be connected to control the water spraying direction on the water spraying hole, and water is sprayed to the rotor blade 1 of rotation with approximate axial direction.

[0018] The radial water retaining ring 8 is arranged at the inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com