Pressure reducing valve

A pressure reducing valve and main valve technology, applied in the field of pressure reducing valves, can solve the problem that the pressure reducing valve is easy to vibrate, and achieve the effect of avoiding vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

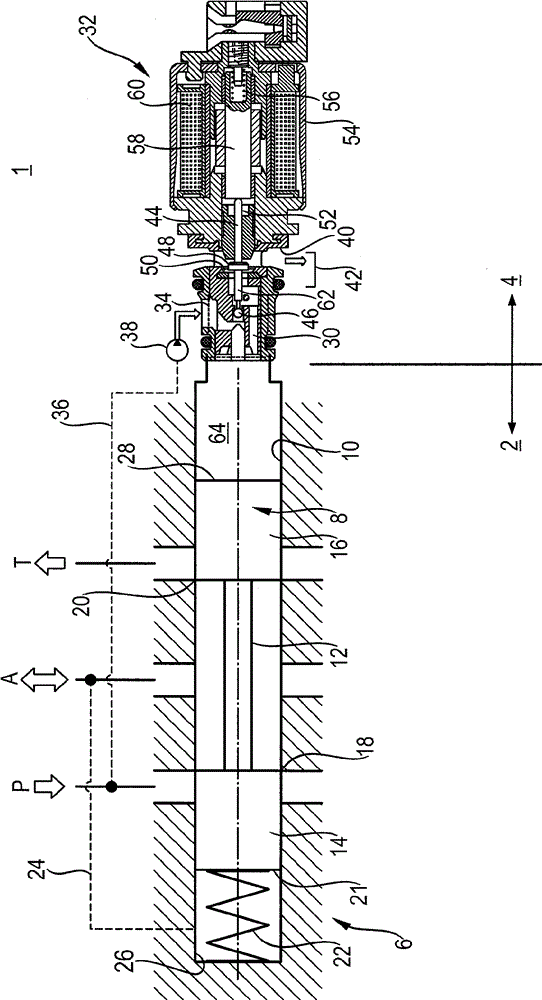

[0073] according to figure 1 A pressure relief valve 1 is shown. The pressure reducing valve is a pre-adjusted 3-way-pressure reducing valve. Such pressure reducing valves are used, for example, in load control transmissions of passenger cars, trucks, buses, construction machines or tractors. In addition, it is suitable for many common hydraulic applications, such as for actuating large directional valves, power brakes, fan drives, hydraulic pumps or hydraulic motors. The pressure relief valve is less susceptible to vibration and has less loss of control oil. It can be used for higher pressures and higher pressure medium volume flows.

[0074] The pressure reducing valve 1 has a main stage 2 and a prestage 4 . The main stage 2 has a main valve 6 . The pressure medium connection between the control oil connection P and the outlet connection A and between the outlet connection A and the tank connection T can be controlled by a control element in the form of a control piston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com