Virtual filter condition sensor

A technology of filters and sensors, which is applied in the field of systems for monitoring such fluid filters, and can solve problems such as increasing the cost of sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In this specification, certain words have been used for the purposes of brevity, clarity and understanding. No unnecessary limitations beyond what is required in the prior art should be inferred therefrom, as these terms are used for descriptive purposes only and are intended to be interpreted broadly. The various devices, methods and systems described herein can be used alone or in combination with other devices, methods and systems. Many equivalents, alternatives, and variations are possible.

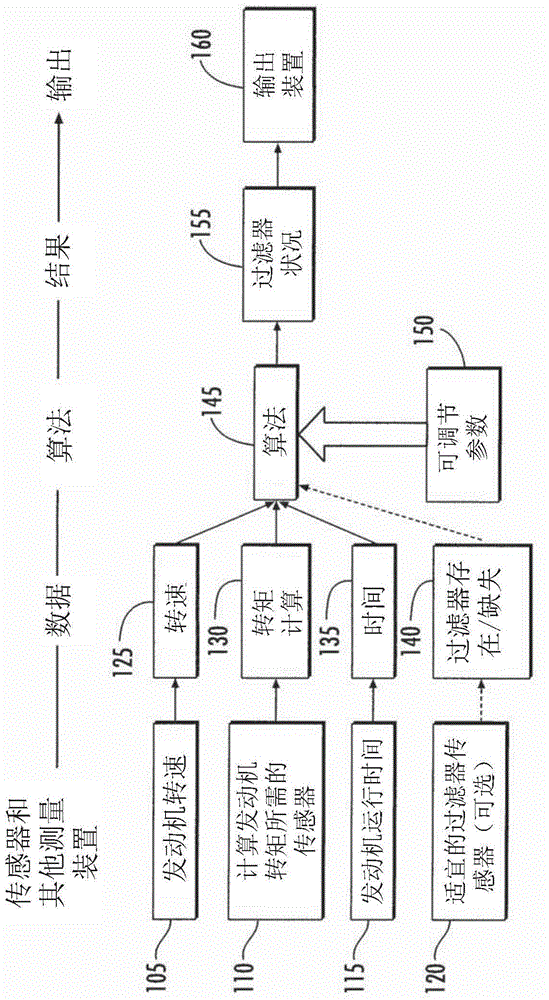

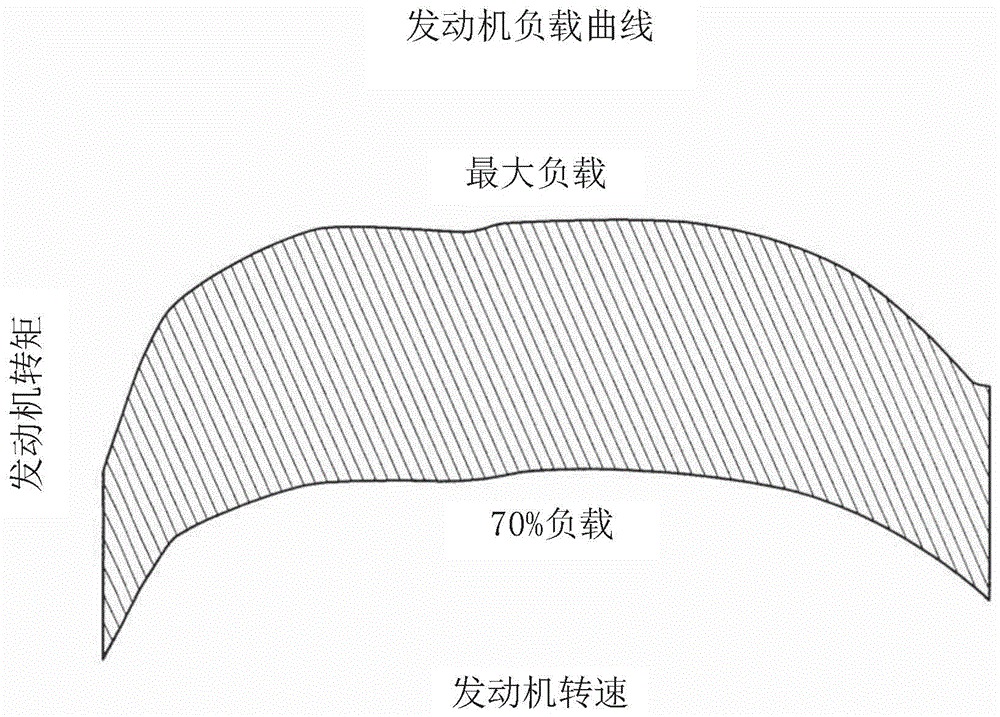

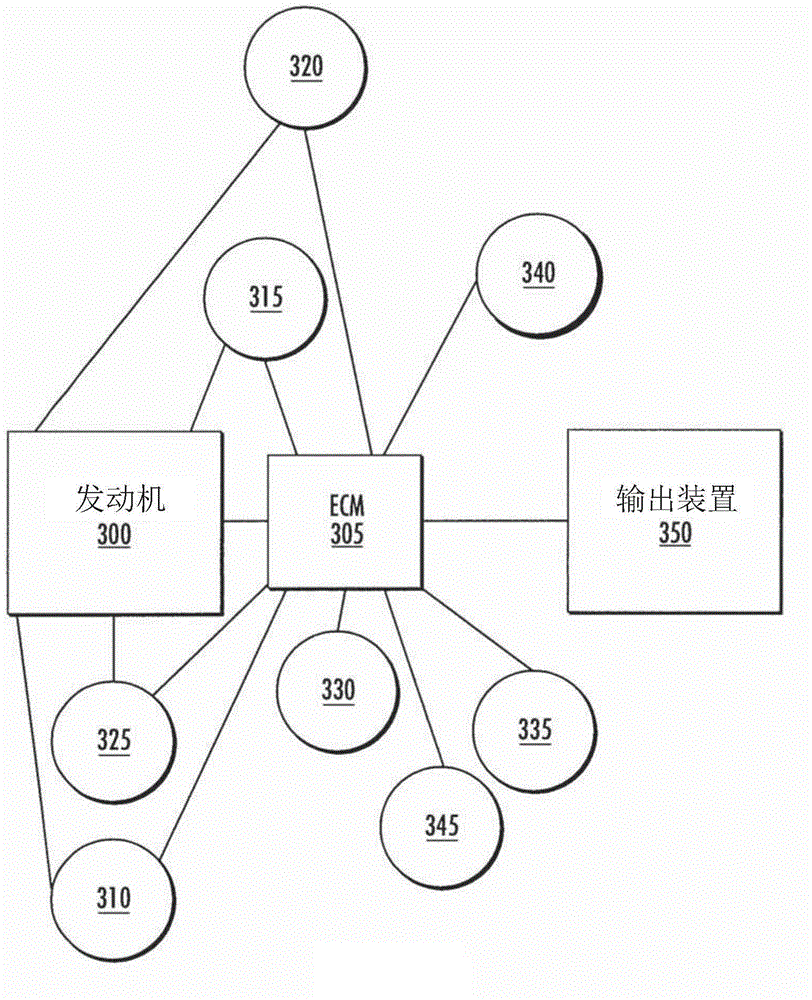

[0018] figure 1 As schematically shown in , a virtual filter condition sensor assesses the condition of an engine fuel and / or lube oil filter. Among other possible things, the virtual filter condition sensor obtains engine run time, engine torque, and engine speed data. Engine speed can be measured directly using on-board sensors. In modern diesel engines, engine torque is usually continuously calculated by the ECM from measured inputs such as engine speed, intake manifold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com