Method for manufacturing seasoned laver

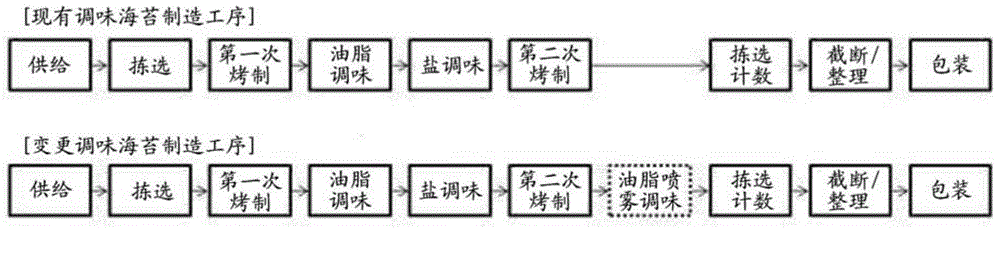

A manufacturing method and technology of seaweed, applied in the field of using oil spraying device separately, can solve the problem of losing the fragrance of sesame oil or perilla seed oil, etc., and achieve the effect of good fragrance and minimized loss of fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: the manufacture of seasoned seaweed

[0045] Using a conveyor, the dry seaweed raw materials stored in a low-temperature warehouse at -5°C are automatically supplied one by one, and then sorted by an image foreign object sorter, and baked for the first time in a baking channel at 50-200°C for 3 seconds Finally, through a sponge roller, 2.1g of mixed oil mixed with corn germ oil and sesame oil at a ratio of 9:1 is applied to the surface of 260*190cm (about 2.6g) of seaweed, seasoned with 0.5g of salt, and Bake for the second time in the oven tunnel at 350°C for 6 seconds.

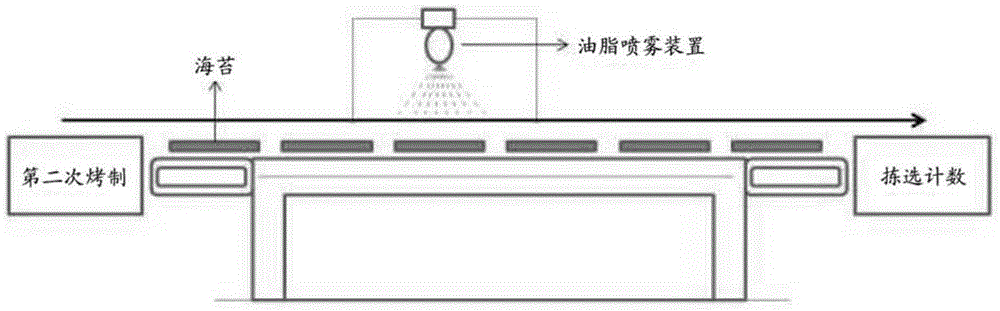

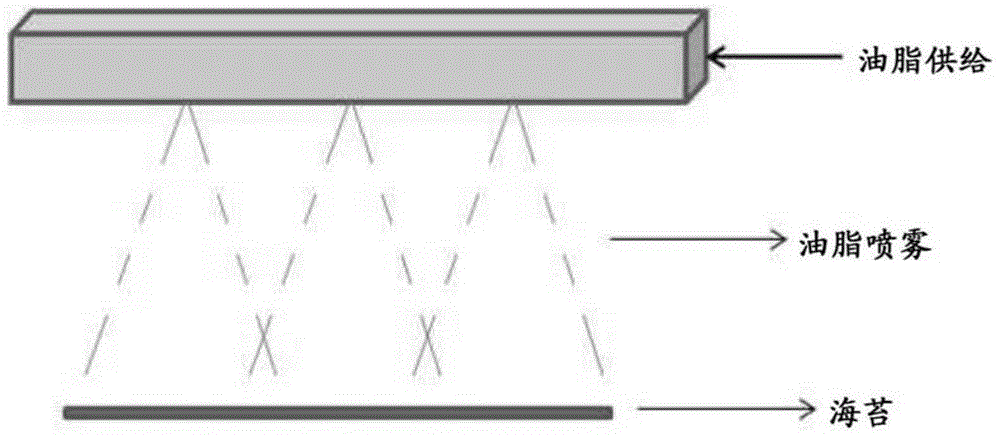

[0046] Seasoned seaweed was manufactured by finely spraying 0.3 g of sesame oil on the surface of the second-baked seaweed using an oil-only spraying device.

[0047] According to the use, the produced seasoning laver is counted every 10 sheets, and the weight is measured, cut off and packed.

experiment example 1

[0048] Experimental Example 1: Sensory evaluation of seasoned seaweed

[0049] A survey group consisting of 60 housewives aged 25-34 For the target, we also provide the existing products of our company (CJ CheilJedang New Crispy Regular Seaweed Lunch Box (CJ )) and the seasoning seaweed product manufactured by the procedure of Example 1, perform a sensory experiment, divide the results into preference characteristics and strength characteristics, and confirm by 5 points of size. The content of the detailed verification evaluates whether the fragrance and oil fragrance are improved and the overall preference. The results are shown in Table 1 below and Figure 4 middle.

[0050]As a result of verifying the quality of consumers, the average overall taste preference of the existing seasoned seaweed is 3.67 points, the average overall taste preference of the seasoned seaweed of the present invention is 3.72 points, and the overall taste preference of the seasoned seaweed man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com