A kind of copper-containing zinc oxide/graphene quantum dot catalyst and preparation method thereof

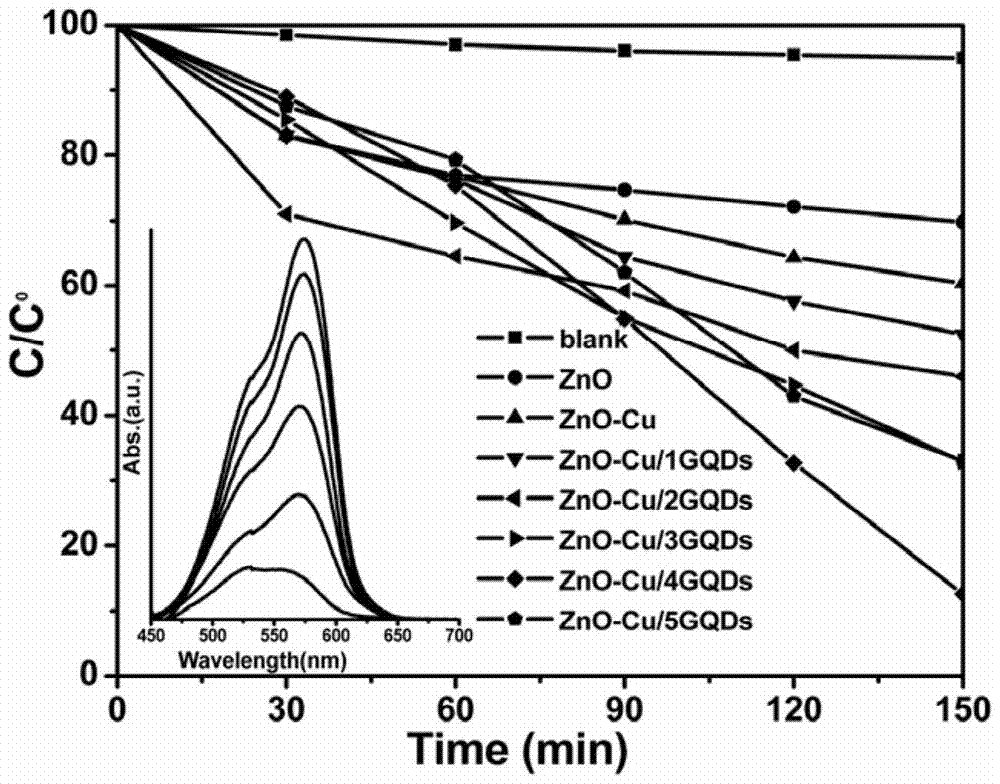

A technology of graphene quantum dots and zinc oxide, applied in the field of materials, can solve the problems of reducing photocatalytic efficiency, photocorrosion, and high cost of precious metals, and achieve the effects of high photocatalytic degradation rate, preventing photocorrosion, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention relates to a copper-containing zinc oxide / graphene quantum dot catalyst and a preparation method thereof. The copper-containing zinc oxide / graphene quantum dot catalyst is a double semiconductor photocatalyst for degrading organic dyes, and the double semiconductor photocatalyst The chemical structure is Cu x / ZnO / GQDs, the x satisfies: 0.2≤x≤0.4. The raw materials for preparing the double semiconductor photocatalyst include high-purity graphite rods, silver / silver chloride electrodes, zinc nitrate, and copper nitrate, and the molar ratio of the copper nitrate to zinc nitrate is 0.2-0.4:1.

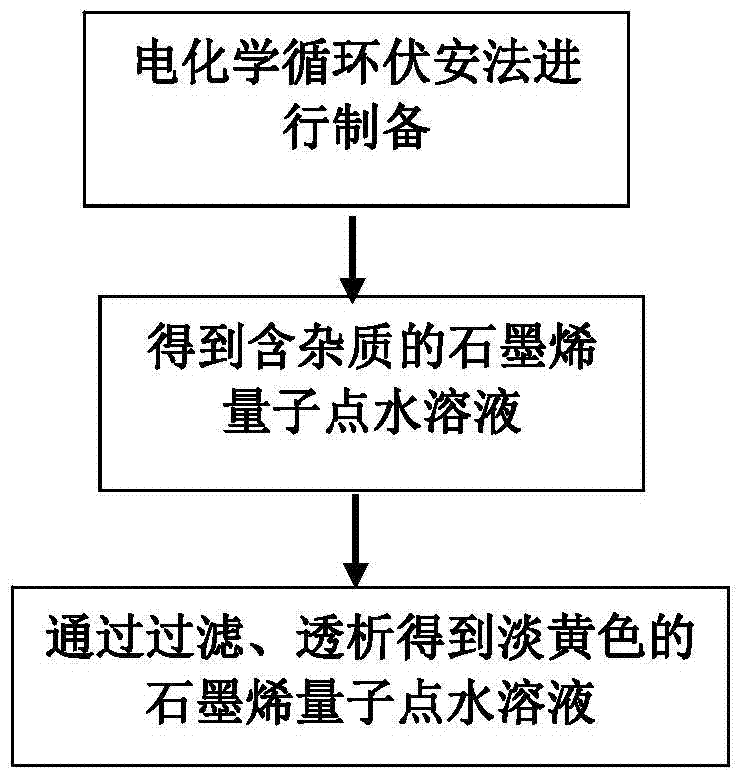

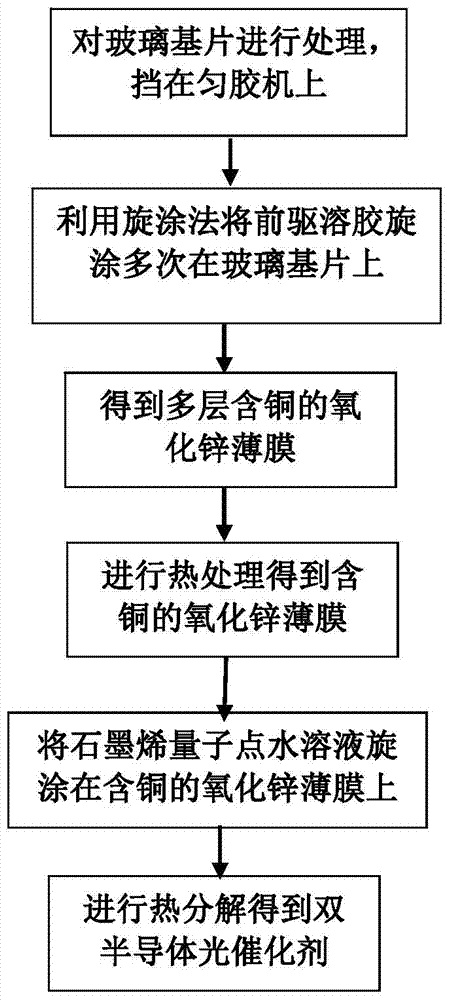

[0035] The preparation method of the double-semiconductor photocatalyst includes three processes, such as figure 2 As shown, first prepare a light yellow aqueous solution of graphene quantum dots, such as figure 1 As shown, the graphene quantum dot aqueous solution was prepared by electrochemical cyclic voltammetry, and the specific operation steps were as follows: ...

Embodiment approach 1

[0042] The high-purity graphite rod is used as the working electrode and the counter electrode at the same time, Ag / AgCl is used as the reference electrode, the concentration is 0.1mol / L, phosphate buffer saline (PBS) with pH=7.0 is used as the electrolyte, and the range of cyclic voltammetry voltage is -5 to 5V, scan rate 0.5 V / s, scan circles 3000. The obtained brown-yellow aqueous solution was filtered with a 220 nm water-based filter head, and then dialyzed with a dialysis bag with a molecular weight cut-off of 3500 Da. The dialysis time was 4 days, and the deionized water was changed every 6 hours.

[0043] According to the proportioning of Cu / (Cu+ZnO)=30%, take the zinc nitrate (Zn(NO 3 ) 2 ·6H 2 O) and 0.1464g of copper nitrate (Cu(NO 3 ) 2 ·3H 2 O), mixed and dissolved in 20 ml ethylene glycol methyl ether solvent, stirred on a magnetic stirrer for 2 hours, then aged for 2 days, to obtain a concentration of Cu that was 0.1 mol / L 0.3 / ZnO precursor sol. The glass...

Embodiment approach 2

[0048] The high-purity graphite rod is used as the working electrode and the counter electrode at the same time, Ag / AgCl is used as the reference electrode, the concentration is 0.1mol / L, phosphate buffer saline (PBS) with pH=7.0 is used as the electrolyte, and the range of cyclic voltammetry voltage is -3 to 3V, scan rate 0.5 V / s, scan circles 5000. The obtained brownish-yellow aqueous solution was filtered with a 220 nm water-based filter head, and then dialyzed with a dialysis bag with a molecular weight cut-off of 3500 Da. The dialysis time was 6 days, and the deionized water was changed every 8 hours.

[0049] Weigh 0.4808g of zinc nitrate (Zn(NO 3 ) 2 ·6H 2 O) and 0.0976g of copper nitrate (Cu(NO 3 ) 2 ·3H 2 O), mixed and dissolved in 20 ml ethylene glycol methyl ether solvent, stirred on a magnetic stirrer for 1 hour, then aged for 3 days, to obtain a concentration of Cu that was 0.1 mol / L 0.2 / ZnO precursor sol. The glass substrate cleaned ultrasonically with ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com