Refrigerator end folding door shell punch forming assembling die and production line with assembling die

A technology of stamping and forming and combining molds, which is applied in the directions of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of low production efficiency, increase human and financial resources, etc., and achieve the effect of improving work efficiency, improving production rhythm, and saving electricity costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

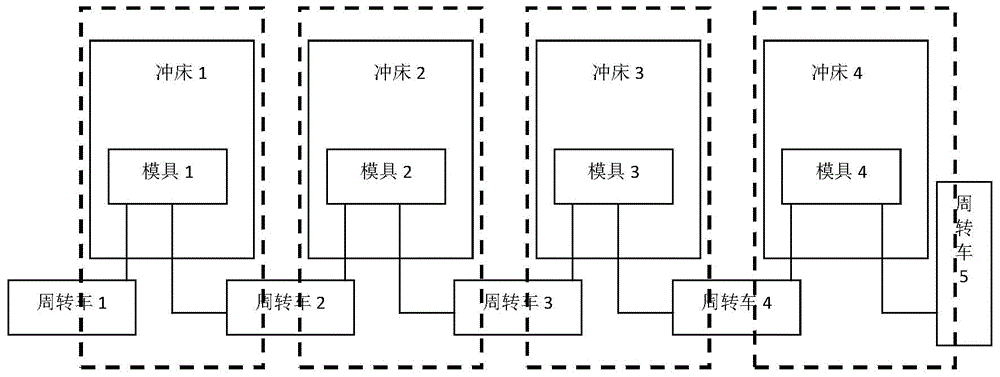

[0041] Such as figure 1 As shown, a combination die for stamping and forming of a refrigerator end-folding door shell includes a punching and bending die 20 and a U-end folding die 30. The punching and bending die 20 and the U-end folding die 30 can be integrally installed on a punching machine It can also be installed on two punches 90 respectively.

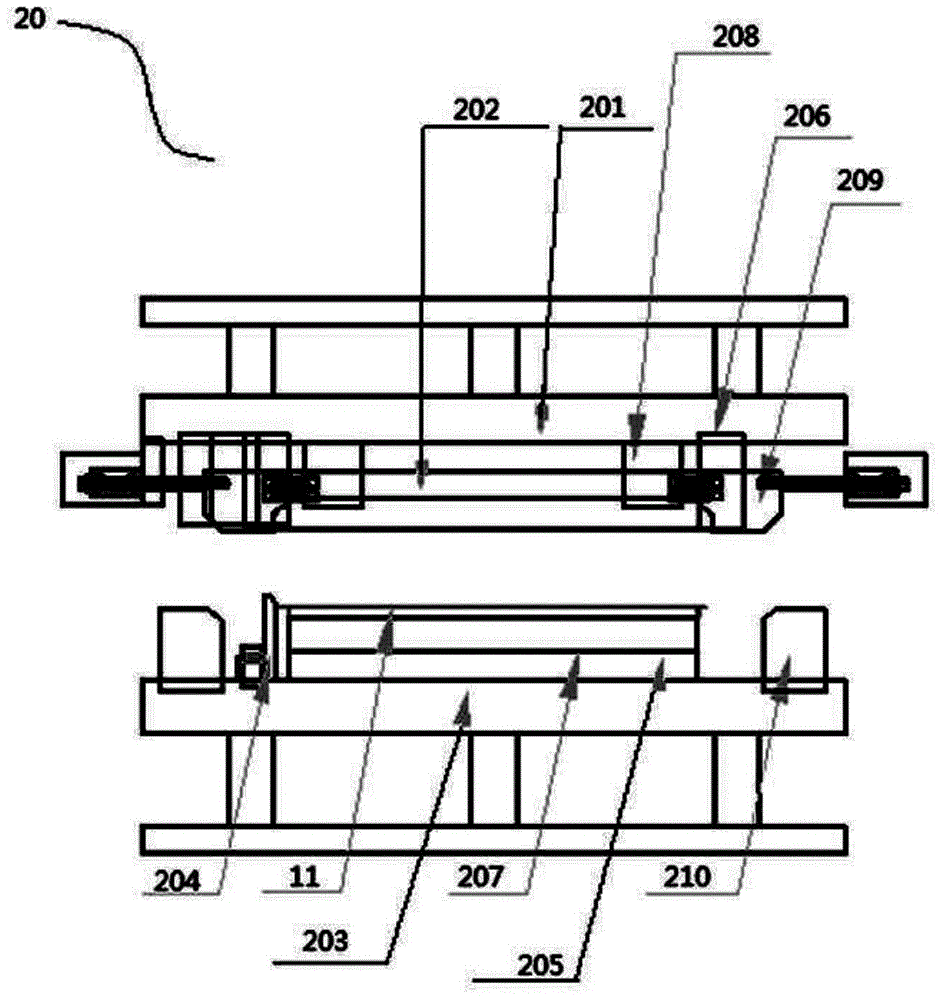

[0042] Specifically, the punching and bending mold 20 includes a first upper mold base 201, a first upper template 202, a first lower mold base 203, a positioning guide post 204, a first lower template 205, a bending mechanism, a front punching mechanism, Side punching mechanism, the first upper template 202 is installed on the lower surface of the first upper mold b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap