Centrifugal casting machine door-stop plate automatic mounting device

A technology of centrifugal casting and shutter plate, applied in the field of centrifugal casting machines, can solve the problems of running fire, poor reliability, low degree of automation and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

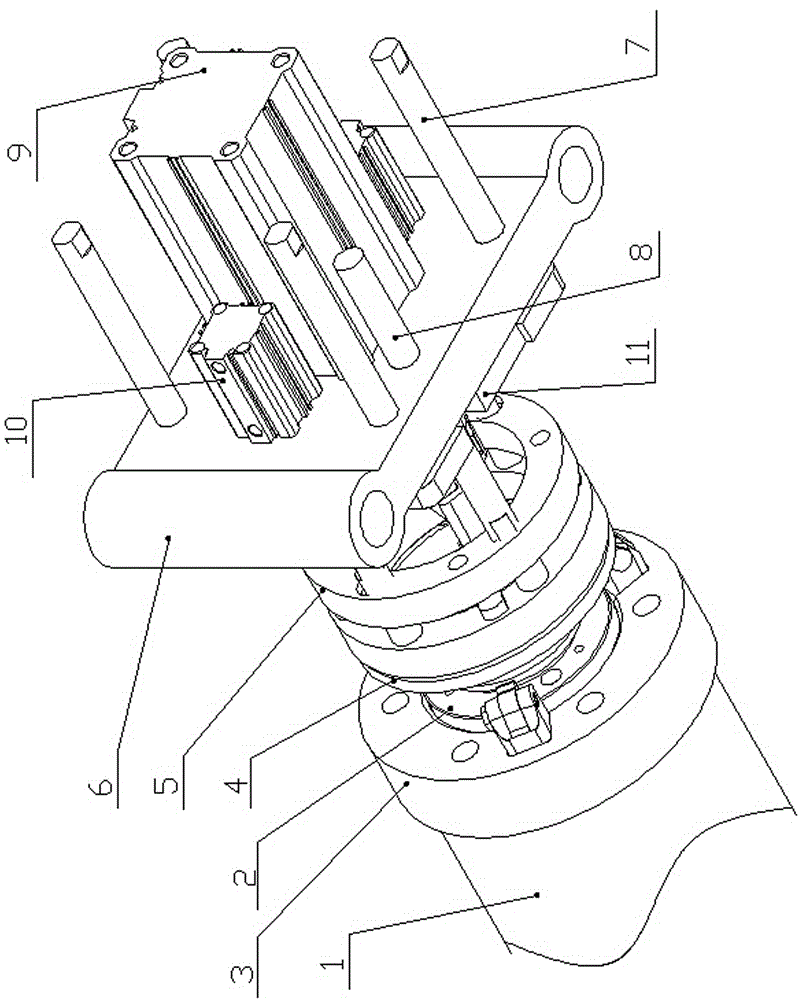

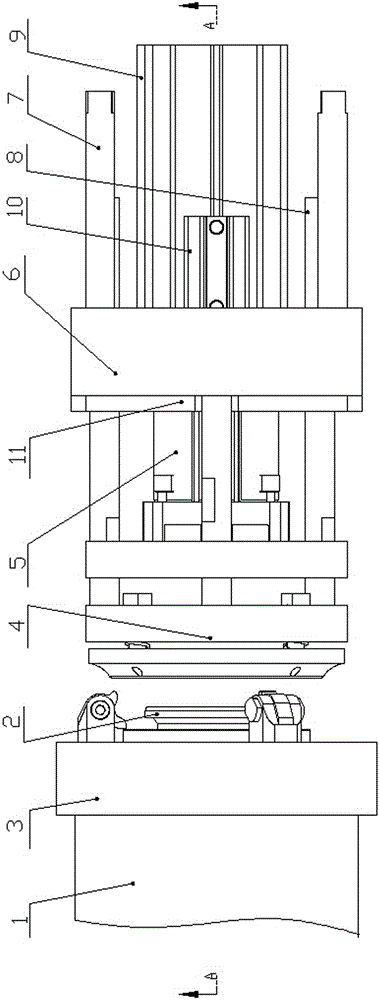

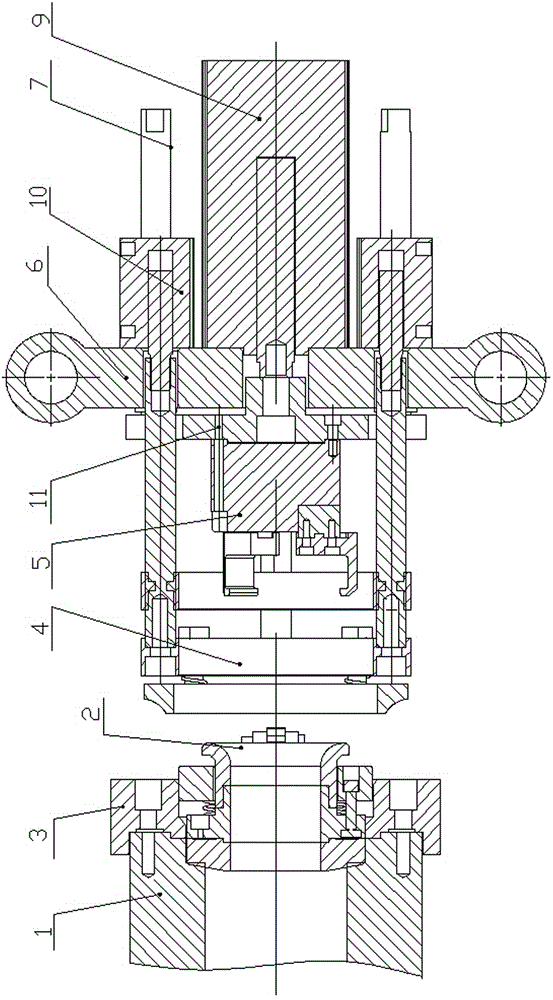

[0030] like Figure 1 to Figure 9 As shown, the automatic installation and removal device for the door baffle of a centrifugal casting machine of the present invention includes a mold 1 and a door baffle 2, the front end of the mold 1 is axially provided with a front retaining ring assembly 3 fixedly connected to it, and the mold 1. The connection position of the front retaining ring assembly 3 is connected through a spigot fit, and the front end surface of the front retaining ring assembly 3 is provided with three claw mechanisms, and the claw mechanisms are evenly arranged around the axis of the front retaining ring assembly 3 Set, the claw mechanism includes a mechanical claw 31, a compression spring 33 and a mounting block 32 fixedly connected to the front retaining ring assembly 3, the mounting block 32 is hingedly connected to the mechanical claw 31, and the mounting block 32 is connected to the mechanical clip A compression spring 33 is arranged between the claws 31, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com