Synchronous rotation drive device for shaft part

A technology of synchronous rotation of shaft parts, applied in the direction of grinding drive devices, grinding machine parts, metal processing equipment, etc., can solve the problems of synchronous drive, large change in positioning diameter, easy to generate torque, etc., to save work The effect of time, guaranteed machining accuracy and reliable torque transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

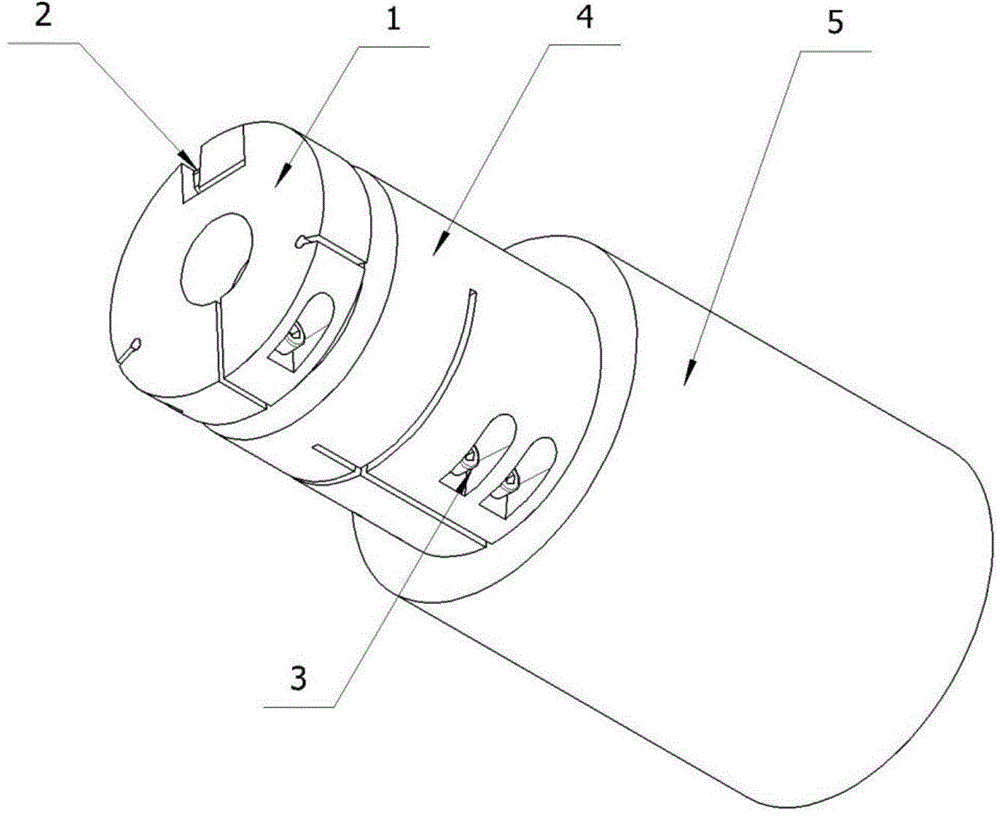

[0029] Generally, the weight of shaft parts is relatively heavy, and it is difficult to overcome the transmission torque. At the same time, the variation of positioning diameter is relatively large. Therefore, a driving device suitable for mass production is required. Aiming at the difficult problems in processing, the present invention proposes a synchronous rotation drive device for shaft parts, such as figure 1 As shown, the device includes a locking flange 1, a gap nut 2, a plurality of compression screws 3 and a drive sleeve 4;

[0030] Its specific structure is:

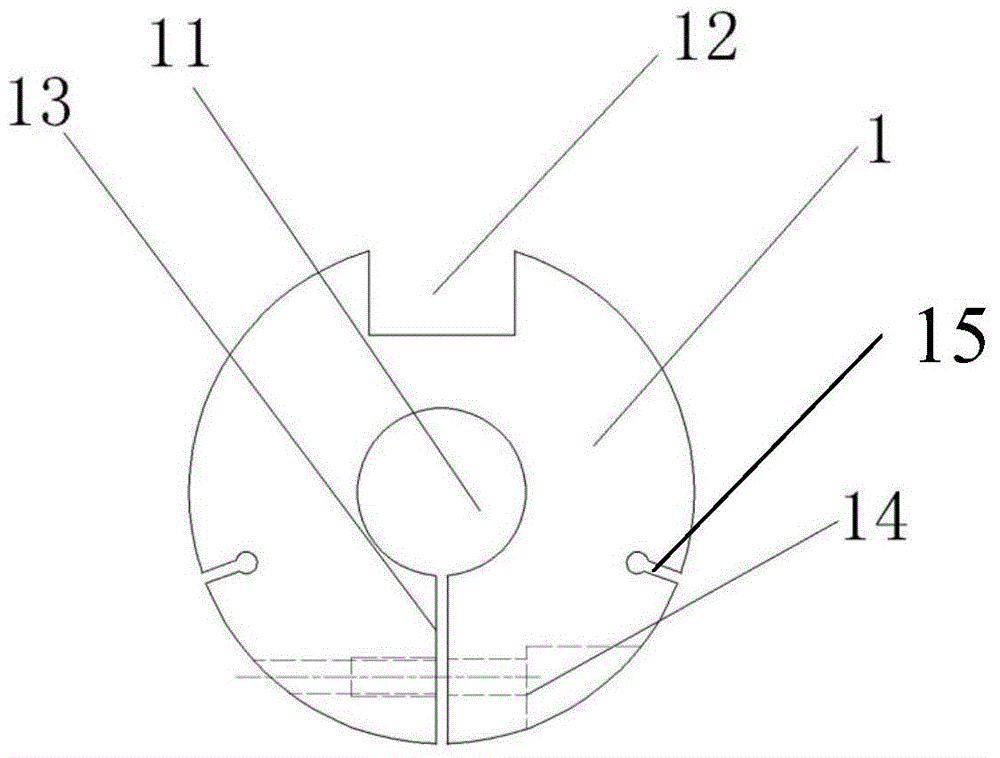

[0031] Such as figure 2 , the locking flange 1 is disc-shaped and has a positioning through hole 11 in the center; the diameter of the positioning through hole 11 is adapted to the outer diameter of the shaft parts to be processed; the locking flange 1 is provided with a groove 12; The locking flange 1 is also provided with a first clearance groove 13 communicating with the positioning through hole 11; the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com