Improved structure based on clamping device for compressing wood of different sizes

A clamping device, wood technology, applied in the direction of clamping devices, wood processing equipment, clamping angle iron, etc., can solve the problem that the clamping size cannot be adjusted, and achieve the effect of improving stability and clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

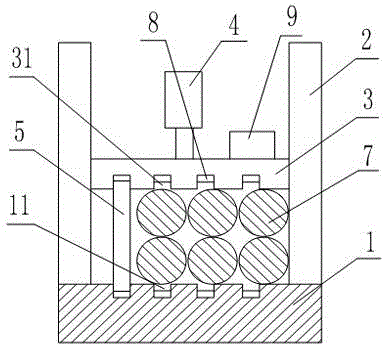

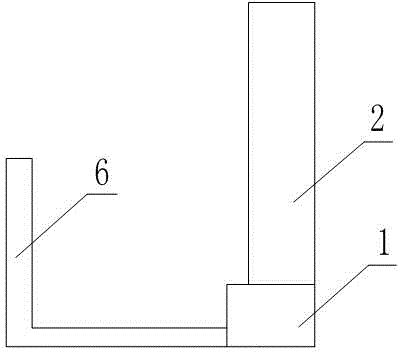

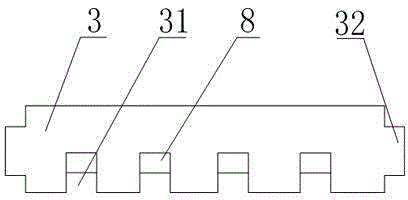

[0021] Such as Figure 1 to Figure 3 As shown, the improved structure of the clamping device based on the compression of different sizes of wood includes a base 1, the side wall of the base 1 is provided with an L-shaped baffle 6, two vertical boards 2 are symmetrically arranged on the base 1, and the inner side of the vertical board 2 A guide groove is provided, and the horizontal plate 3 of the rectangular parallelepiped structure is arranged between the two vertical plates 2 through the cooperation of the protrusions 32 provided at its two ends and the guide grooves. The top of the vertical plate 2 is connected with a hydraulic cylinder 4, and the The top is provided with a weight block 9, the bottom of the vertical plate 2 is provided with four card slots I31, the upper end of the base 1 is provided with a card slot II11 that matches the card slot I31, and the bottoms of the card slot I31 and card slot II11 are provided with elastic sheets 8. The card board 5 is set betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com