Material transport vehicle

A technology for conveying vehicles and materials, which is applied in the field of material transmission and can solve problems such as reduced equipment use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

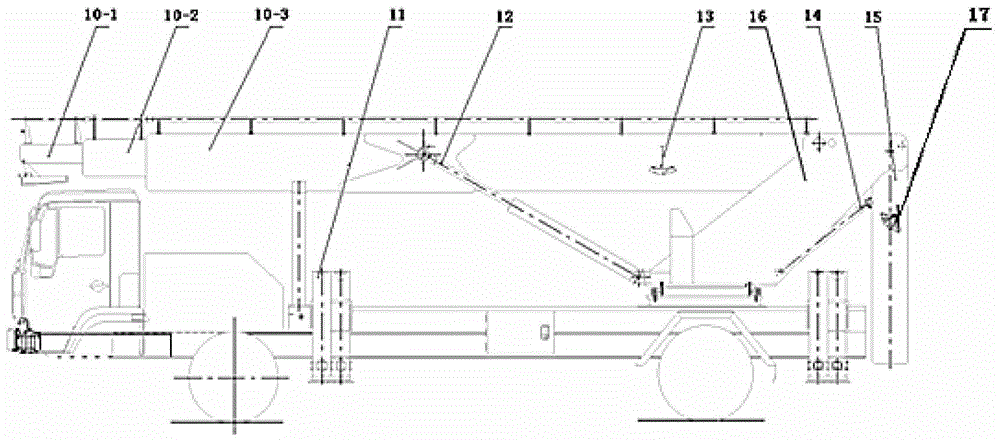

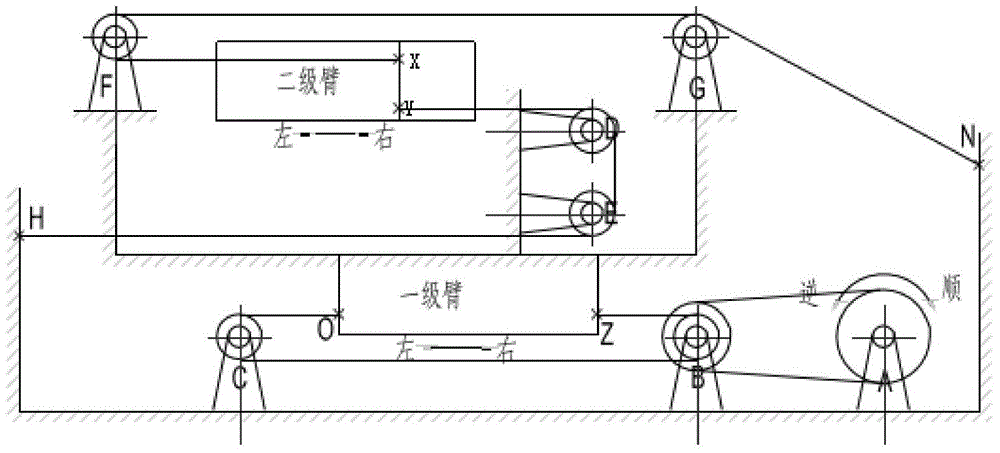

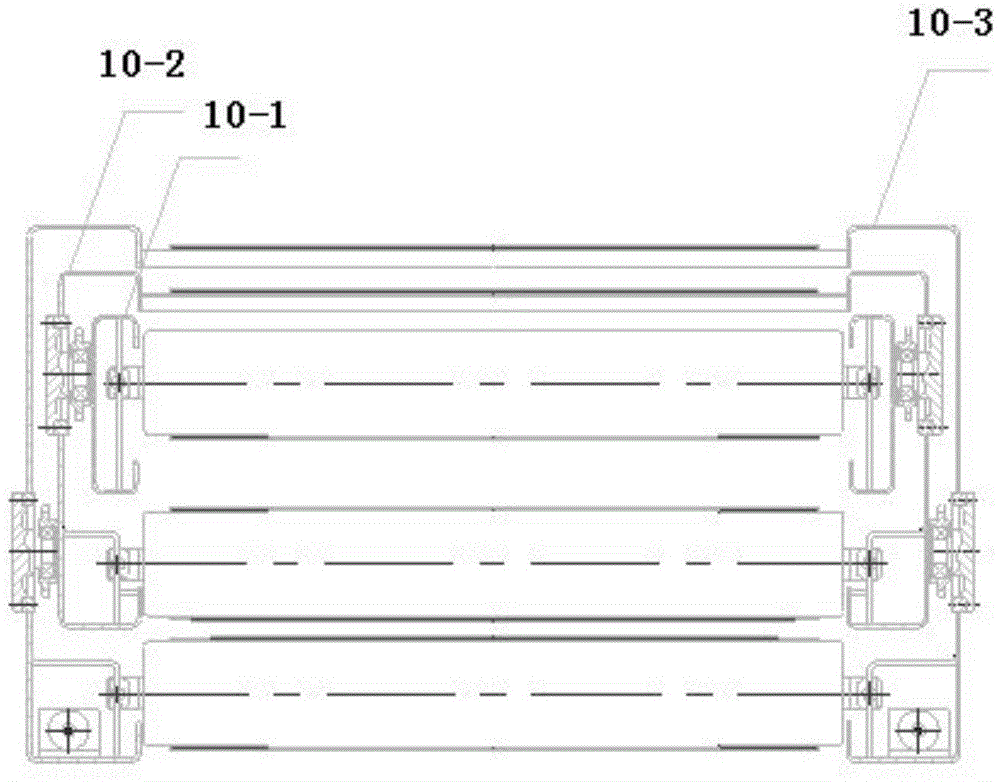

[0021] combine figure 1 , a material conveying vehicle, comprising a vehicle body, a three-stage telescopic arm arranged on the vehicle body, and a conveyor belt deviation correction device arranged at the rear end of the third-stage telescopic arm, the three-stage telescopic arm comprising a first-stage fixed basic arm 10- 3 and two-stage telescopic arms, the first-stage telescopic arm 10-2 is slidably nested in the basic arm, and the second-stage telescopic arm 10-1 is slidably nested in the first-stage telescopic arm 10-2. The rear end of the basic arm 10-3 is rotatably connected with the support column 16 provided on the vehicle body through a bearing, and the middle part of the basic arm 10-3 is connected with the vehicle body through the forearm lift cylinder 6. The material conveying vehicle further includes a rear conveying arm 15 , the front end of the rear conveying arm 15 is rotatably connected with the upper end of the support column 16 through a bearing, and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com