Processing equipment for refrigerator seals

A processing equipment and sealing technology, applied in the field of refrigerator processing equipment, can solve the problems of complicated and cumbersome operations, and achieve the effects of ensuring the sealing effect, prolonging the service life, and being easy to place.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

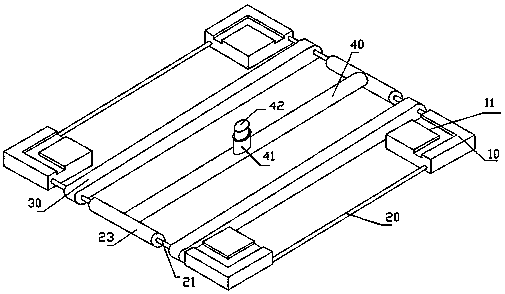

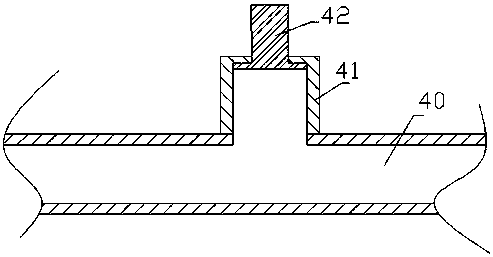

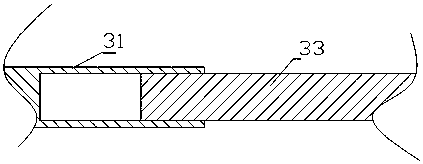

[0022] Such as figure 1 The shown processing equipment for refrigerator seals includes four installation molds 10 and four connecting rods 20, the connecting rods 20 connect the installation molds 10 in turn, the installation molds 10 are provided with right-angle grooves 11, and the right-angle grooves of the four installation molds 10 Groove 11 constitutes four right angles of a rectangle; four connecting rods 20 are arranged in parallel in pairs, connecting rods 20 are telescopic connecting rods 20, wherein, connecting rods 20 include two sections of connecting rods 21 and connecting cylinder 23, connecting cylinder 23 is socketed with the free ends of the two sections of connecting rods 21; elastic parts are connected between the free ends of the two sections of connecting rods 21, and springs are used as the elastic parts in the present embodiment; The telescopic horizontal plate 30, two horizontal plates 30 are arranged symmetrically with the sealing cylinder 40 as the c...

Embodiment 2

[0026] Difference with embodiment 1 is that the processing equipment among the present invention is arranged on the workbench 19, is connected with cutting knife frame 50 on the mounting mold, the clip on the cutting knife on the cutting blade frame 50 and the right-angle groove on the mounting mold The angle is 45 °, and the adjacent cutting knives are symmetrically arranged; the workbench 19 is also provided with a fence 51, and the fence 51 is symmetrically arranged with the adjacent cutting knife rest 50; during work, the seal is placed on the processing equipment to ensure The seal is located on the right-angle groove; after the front end of the seal is against the slab 51, the cutting knife cuts the seal. At this time, the seal is cut into three sections, and the second section of seal 62 then directly falls into the groove below; After one section of seal 61 is moved to another groove and placed, after the placement of four sections of seals on the processing device is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com