A kind of high-performance asphalt mixture for steel bridge deck pavement and preparation method thereof

A technology of asphalt mixture and bridge deck pavement, which is applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of harsh use conditions, inability to take into account high and low temperature performance at the same time, and achieve total cost Low, good environmental benefits, good low temperature toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

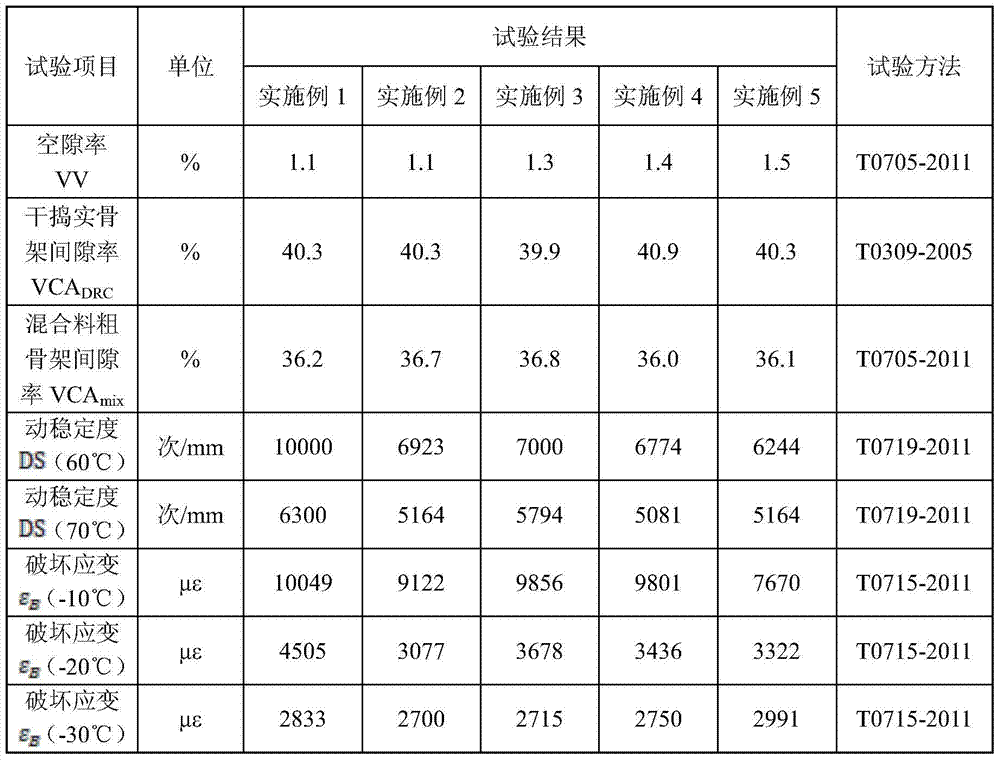

Examples

Embodiment 1

[0040] For high-performance asphalt mixture, the mass percentage of each component is as follows:

[0041] Limestone with a particle size of 2.36-4.75mm: 78.8%

[0042] "Lobo" high modulus admixture: 1.0%

[0043] 40 mesh vulcanized rubber powder: 3.6%

[0044] Finished SBS modified asphalt: 10.6%

[0045] Limestone mineral powder: 4.0%

[0046] Cement: 2.0%.

[0047] The preparation method is as follows: place limestone aggregates with a particle size of 2.36-4.75mm in an oven at 190°C for 4 hours; Aggregate, 101.5g of "Lubao brand" high modulus asphalt concrete admixture, 365.5g of 40 mesh vulcanized rubber powder were added to the pot and mixed for 3 minutes, then 1076.1g of finished SBS modified asphalt was added and mixed for 3 minutes, and finally added 406.1g of limestone mineral powder and 203g of cement were mixed for 2 minutes to obtain high-performance asphalt mixture.

[0048] The mixture was rolled and formed into rut specimens with a rutting machine, and subj...

Embodiment 2

[0050] For high-performance asphalt mixture, the mass percentage of each component is as follows:

[0051] Limestone with a particle size of 2.36-4.75mm: 82.0%

[0052] PR MODULE high modulus asphalt concrete anti-rutting agent: 1.5%

[0053] 40 mesh waste tire rubber powder: 3.5%

[0054] Self-made SBS modified asphalt: 12.0%

[0055] Limestone mineral powder: 1.0%.

[0056] The preparation method is as follows: place limestone aggregates with a particle size of 2.36-4.75mm in an oven at 190°C for 3 hours; mm limestone aggregate and 146.3g of PR MODULE high modulus asphalt concrete anti-rutting agent, 341.5g of 40 mesh waste tire rubber powder were mixed for 3 minutes, then 1170.7g of self-made SBS modified asphalt was added and mixed for 3 minutes, and finally, 97.6 g of limestone mineral powder mixed for 3 minutes to obtain high-performance asphalt mixture.

[0057] The mixture was rolled and formed into rut specimens with a rutting machine, and subjected to high-tempe...

Embodiment 3

[0059] For high-performance asphalt mixture, the mass percentage of each component is as follows:

[0060] 2.36 ~ 4.75mm basalt: 80.0%

[0061] PR MODULE high modulus asphalt concrete anti-rutting agent: 1.0%

[0062] 40 mesh rubber powder: 3.1%

[0063] Finished SBS modified asphalt: 12.5%

[0064] Cement: 3.4%.

[0065] The preparation method is as follows: place the basalt aggregates with a particle size of 2.36-4.75mm in an oven at 180°C for 4 hours; mm basalt aggregate, mixed with 102.5g of PR MODULE high modulus anti-rutting agent for asphalt concrete, 317.8g of 40 mesh rubber powder for 1.5min, then added 1281.3g of finished SBS modified asphalt and mixed for 1.5min, and finally added 348.5g The cement is mixed for 1.5 minutes to obtain high-performance asphalt mixture.

[0066] The mixture was rolled and formed into rut specimens with a rutting machine, and subjected to high-temperature rutting dynamic stability test and low-temperature trabecular bending failure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com