Quick coupling for fixation of mining rails

A technology for rails and mines, applied in the field of quick joints for rail-fixing in mines, can solve the problems of high use cost, low assembly efficiency, inconvenient portability, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

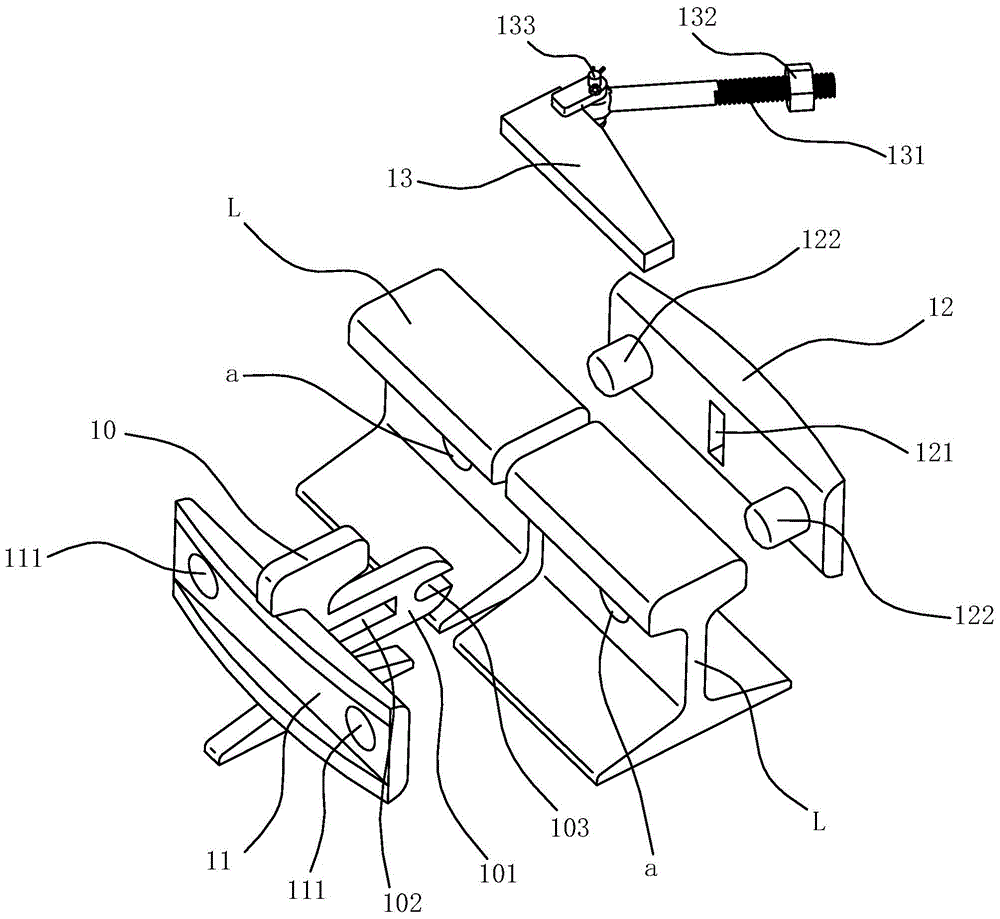

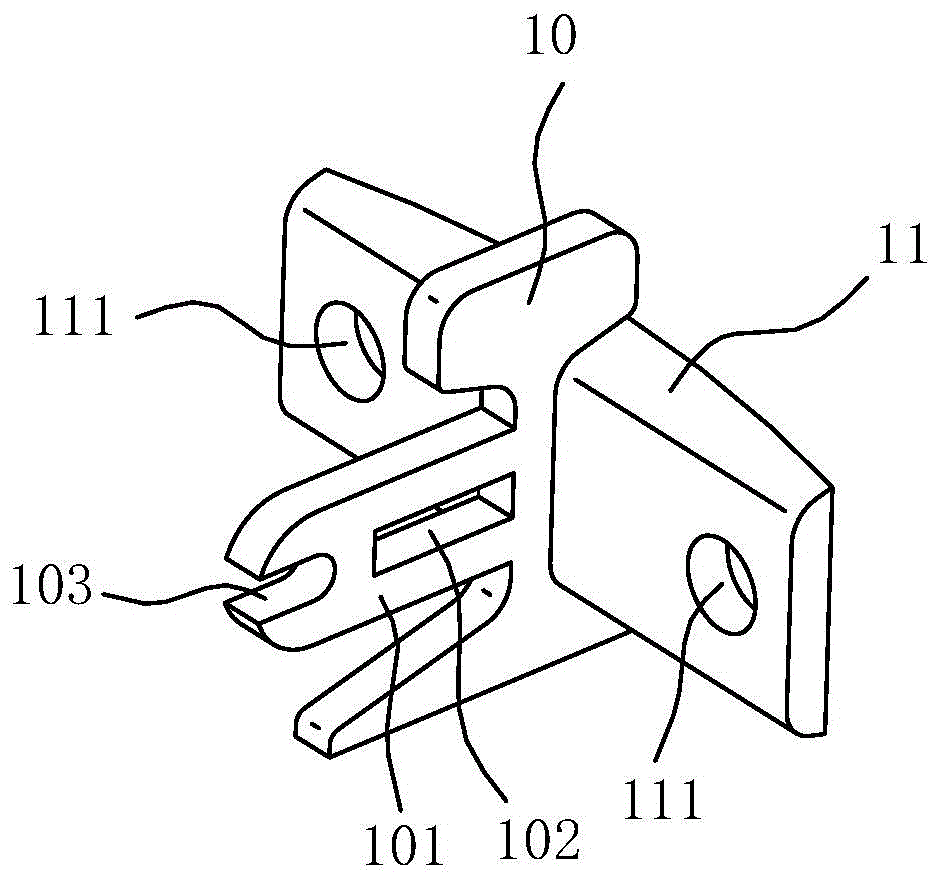

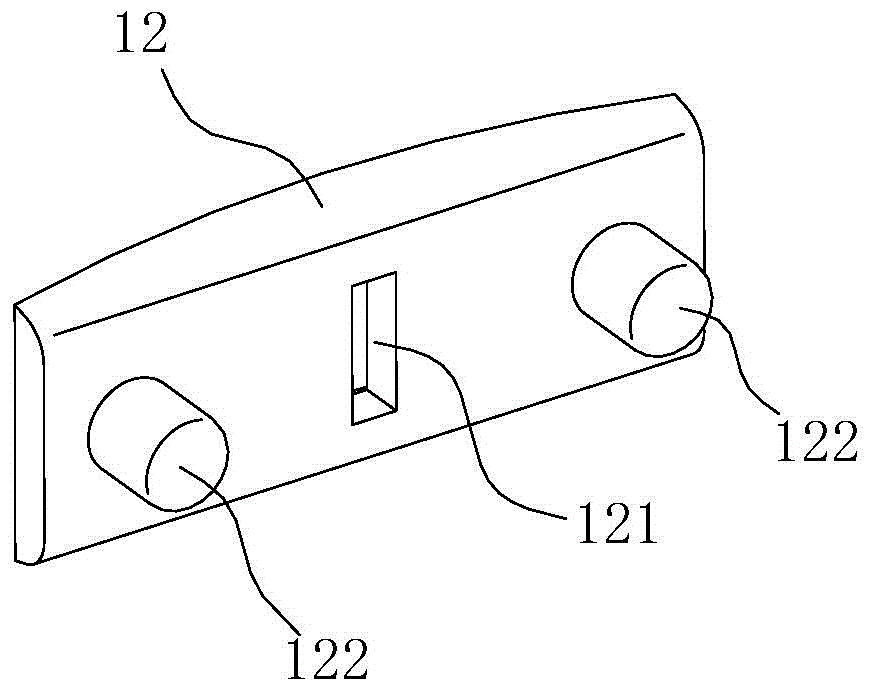

[0010] Such as Figure 1-5 As shown, a quick joint for rail-fixing of a mine track includes a first splint 11 and a second splint 12 clamped on both sides of the web of the rail L, and an insert plate 10 inserted between the end faces of the two rails L; at least one of them There are bolts 122 on the splint, and at least two bolts 122 are provided, and the bolts 122 are respectively inserted into the connecting holes a reserved on the webs of the two rails L and extend to the pin holes 111 on the opposite splint; The insert plate 10 is provided with an extension portion 101 extending toward at least one side of the web of the rail L. The extension portion 101 penetrates the through hole 121 provided on the first splint 11 and / or the second splint 12, and the extension portion 101 is provided with a jack 102 penetrating the extension part 101 along the length direction of the track L, and a wedge 13 is inserted in the jack 102, and the wedge 13 abuts against the first splint 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com