A load conversion method for hydraulic lifting equipment replacement

A technology of hydraulic lifting and switching methods, applied in the processing of building materials, preparation of building components on site, pillars, etc., can solve problems such as high safety risks, and achieve the effect of safe load switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

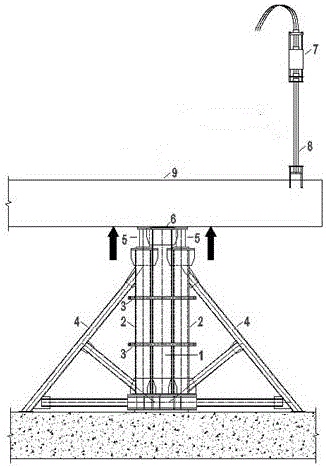

[0013] Such as figure 1 As shown, in the present invention, when the steel structure roof 9 is in the hydraulic lifting construction process, the failure of the lifting cylinder 7 cannot be ruled out and must be replaced or the lifting steel strand 8 is broken, the load conversion method of the present invention will be used to lift the lifting mechanism. The load can be safely and reliably transferred to the temporary support load transfer device, the specific steps are as follows:

[0014] The technical personnel issue the equipment replacement plan, and determine the specifications and sizes of the components of the temporary support load conversion device of the present invention through calculation and analysis, and use ANSYS for finite element analysis of complex nodes;

[0015] The type of hydraulic jack 5 is determined: the tonnage of the jack 5 is determined according to the reaction force value of the temporary support point; according to the deformation difference Δ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com