Control system and control method for multi-station rotary flocking

A control system and multi-station technology, applied in the control of multi-station rotary hair planting, the control system of multi-station rotary hair planting, and the field of control systems, can solve the interference between the hair-planting nozzle and the brush plate, the large size and weight of the hair-planting machine, Problems such as space occupation above the drilling and planting table

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

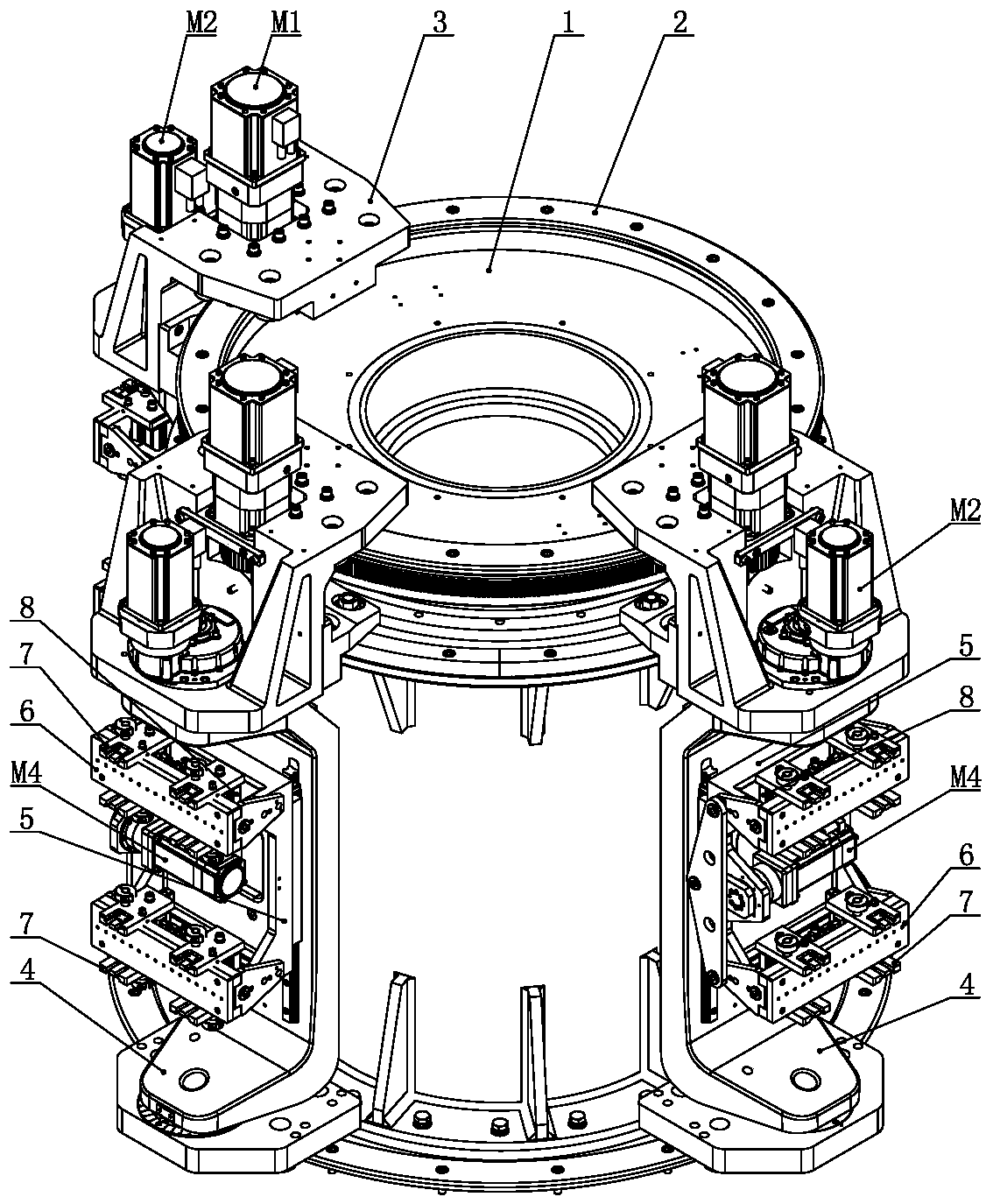

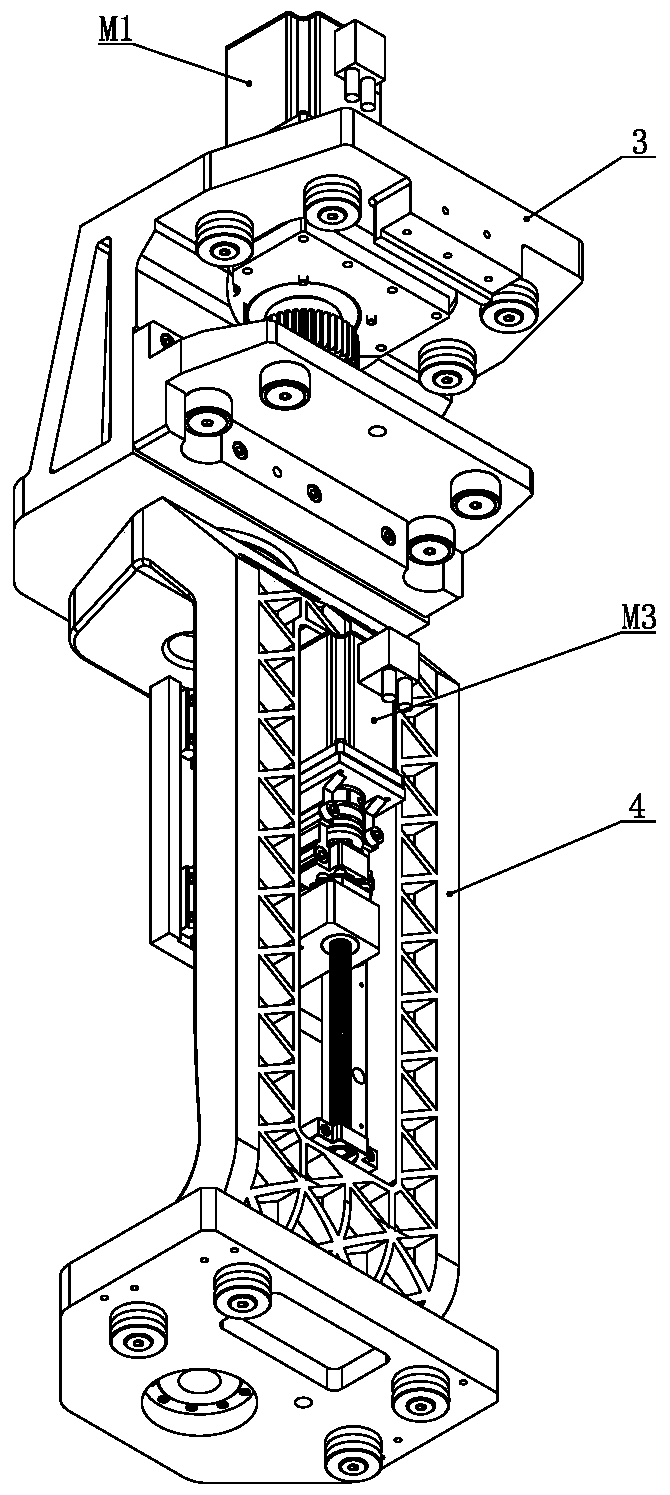

[0028] Such as figure 1 , figure 2 As shown, the multi-station rotary tufting machine in the present invention comprises a workbench central cylinder 1, an annular guide rail 2 is installed on the outer periphery of the workbench central cylinder 1, and a loading and unloading station and a drilling station are arranged on the circumference of the annular guide rail 2. And the tufting station, each station is equipped with a station turntable 3 respectively, and each station turntable 3 is equipped with a rotatable workbench support plate 4 respectively, and each workbench support plate 4 is respectively equipped with a liftable The brush body workbench 5 and the brush body workbench 5 are respectively equipped with swingable brush body mounting plates 6 , and the upper and lower sides of each brush body mounting plate 6 are respectively provided with jaws 7 .

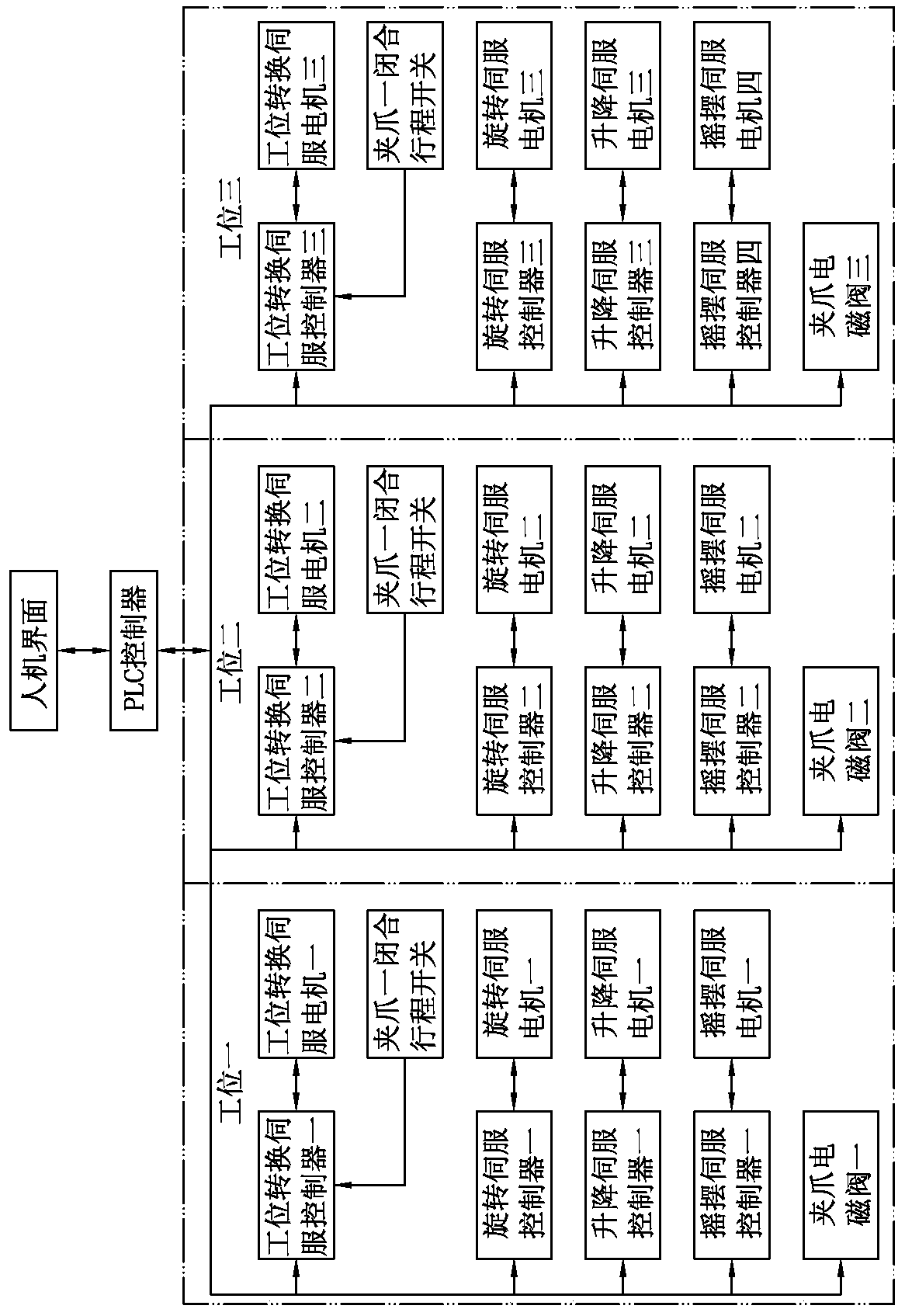

[0029] Such as Figure 3 to Figure 8 As shown, in the control system of multi-station rotary tufting of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com