Shaft seal

一种轴密封、密封元件的技术,应用在发动机的密封、机械设备、发动机元件等方向,能够解决部件数量增多、密封元件共同旋转、产品单价变高等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

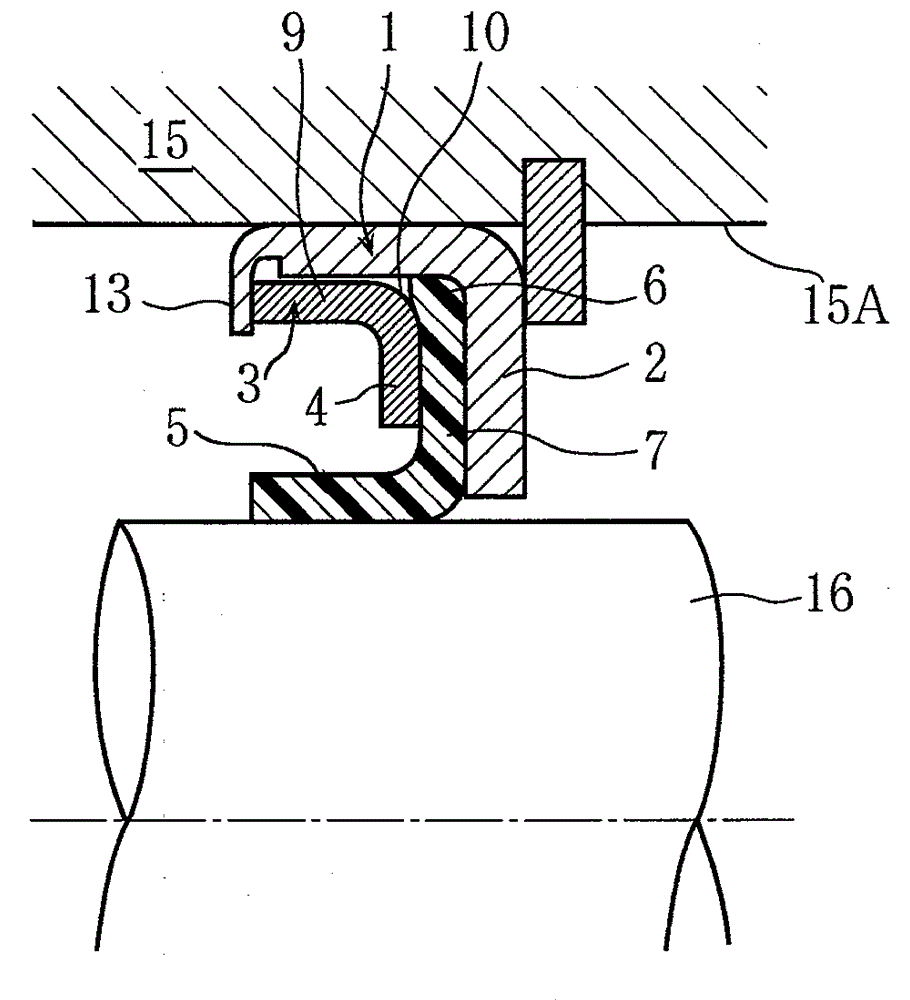

[0013] Preferred embodiments of the present invention will now be described with reference to the accompanying drawings.

[0014] Figure 1 to Figure 3 A first embodiment of the invention is shown. The shaft sealing device is used, for example, in EGR-V, vacuum pump, compressor, (oil pressure or pneumatic) reciprocating cylinder (not shown in the figure). In addition, shaft seals are available for rotary as well as reciprocating motion.

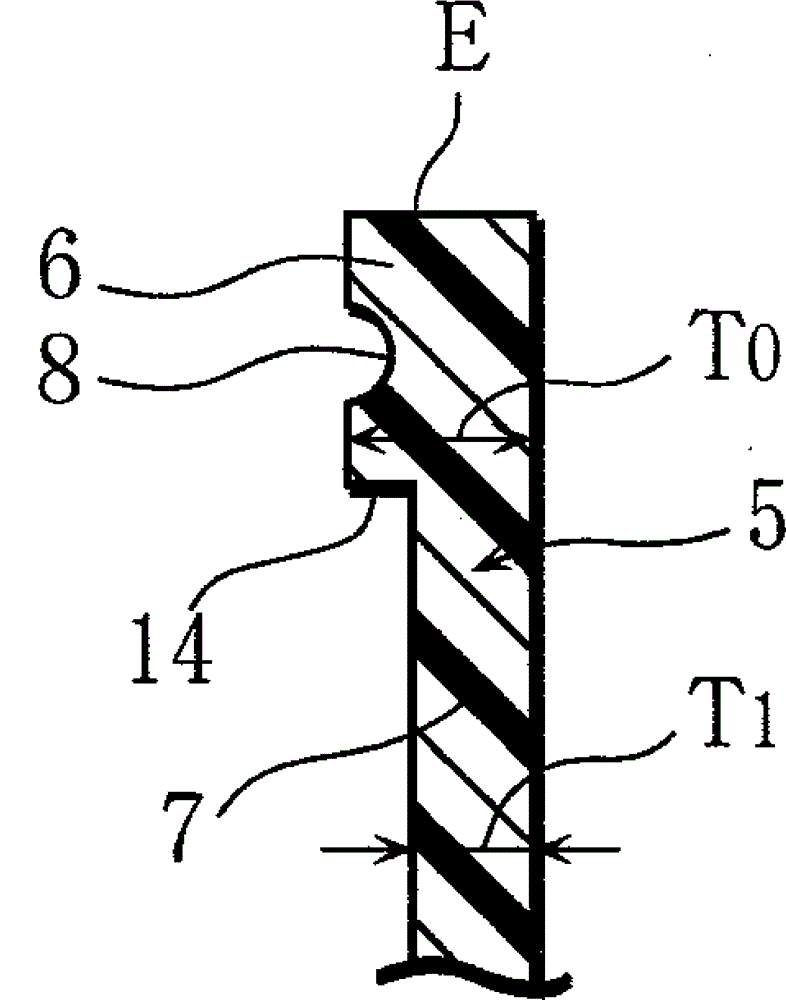

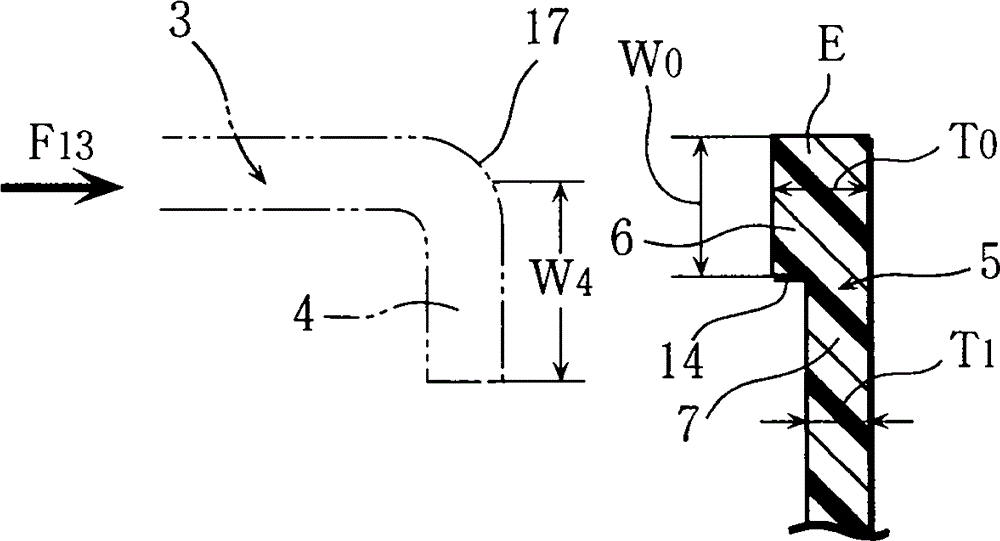

[0015] This shaft seal device is attached to a cylindrical space portion between a circular hole portion 15A of a housing 15 and a shaft 16, and is provided with a sealing member 5 formed of resin adjacent to the shaft 16 (such as figure 1 shown in ). The thickness dimension T of the outer peripheral edge 6 of the sealing member 5 formed of a resin such as PTFE held by the inner peripheral wall portion 2 of the outer case 1 formed of metal and the inner peripheral wall portion 4 of the inner case 3 formed of metal 0 set to image 3 great...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com